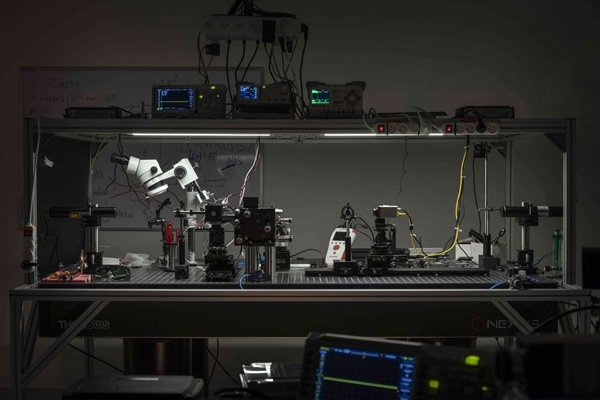

October 2, 20236day,Mohou.com has learned that,Startups from Israel3DM has developed new laser powder bed fusion (SLS) technology and is steadily progressing towards the official release of its first hardware solution in the near future. It is reported that the new technology developed by this young company founded in 2016 will open up the possibility of new materials and make the technology more accessible.

Quantum cascade laser for 3DM

What sets 3DM apart from the competition in the SLS field is its Quantum Cascade Laser (QCL). Developed by Daniel Majer, founder of 3DM and expert in electro-optical laser and semiconductor technology, QCL is a solid-state laser whose high-energy beam can be tuned to specific wavelengths in the spectrum mid infrared. In practice, this means that 3D printing lasers can be programmed to match the specific melting properties of almost any thermoplastic material, opening up enormous potential for printing new types of powdered plastic materials. The laser’s precision and melting intensity also help material molecules bond together, giving parts improved mechanical and isotropic properties.

The approach to developing lasers that match the energy absorption properties of specific thermoplastics differs from most existing lasers. SLS technology. These techniques often rely on less efficient lasers that can only process a small range of materials and materials containing additives to improve energy absorption. These additional developments and work may increase the cost of SLS technology and consumables and limit the feasible range of thermoplastics. QCL technology overcomes these obstacles by using lasers to melt specific materials in the most efficient way possible. 3DM’s QCL technology has been successfully used to print all types of SLS materials, including PA, PP and TPU, and can theoretically be used with any powdered thermoplastic material.

In addition to variable wavelength, quantum cascade lasers provide other advantages. Lasers are small, the size of a grain of rice, and very affordable. according to According to 3DM, each tunable wavelength laser costs only a few dozen dollars. As a result, 3DM was able to develop a beam head system that cost-effectively hosts up to six lasers that can operate simultaneously for faster print speeds (the beam heads themselves can be combined for greater scalability ). The laser also has greater precision than CO2 lasers, allowing very high resolution.

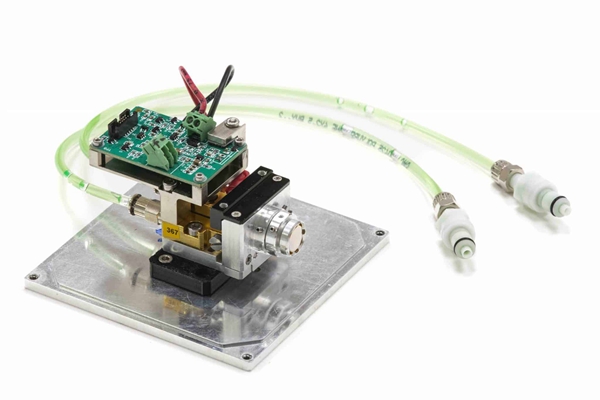

△Each laser is divided into several laser components, after which each component is carefully inspected and tested, and assembled on the cooling equipment with the collimating lens and driver. Once assembled, these components form the “laser module”.

Ido Eylon, CEO of 3DM, summarizes the main advantages of 3DM laser innovation: “The main advantage of QCL technology is the efficiency of melting plastic materials. This brings four main advantages: the diversity of materials, the high resolution and the improved surface finish. These advantages, the expected price is cost effective and the system is an open platform, allowing manufacturers to use a variety of materials and keep operating costs low.

What’s Coming Soon from 3DM

existIn May 2023, 3DM is preparing for the production of two industrial-grade 3D printers: a compact professional system equipped with a single laser module and a large machine equipped with a four-laser configuration. The former will launch first and is ideal for adopters seeking low-volume production and lower entry costs, while the latter is designed for high-throughput industrial applications. Ultimately, the company was primarily interested in industrial mass production.

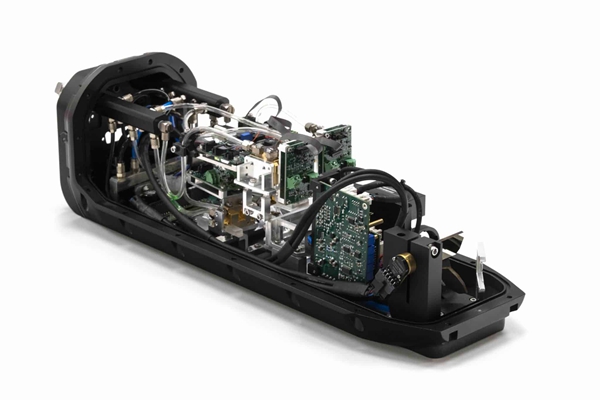

△Four different laser modules are assembled in a housing with other optics that combine all the laser light into a high quality, high power beam – aka the beam head (shown in the picture), on the powder Creates a point melted laser.

Since Since May, 3DM has made steady progress toward releasing its first system. “We further stabilized the beam head, made other improvements to it and shipped one to a strategic partner for testing on their own equipment and facilities,” Eylon said. “We are looking forward to this collaboration as it will be the first time 3DM technology is tested at a customer site and in a production environment. Additionally, we hope to gain a lot of very valuable knowledge and information about production applications of additive manufacturing through this event We will use this information in the future making it more suitable for production applications.

3DM has also expanded its agreements with its strategic manufacturing partners to produce its single-beam laser heads. With this latest agreement, 3DM will receive its first prototype system in early 2024. Eylon added: “We are planning to launch the product early next year and due to the huge market interest, we have started taking pre-orders of potential customers selected to guarantee their place in the queue. Next, 3DM also plans to launch ancillary products to supplement. » Its laser powder bed fusion systems, including automation and post-processing equipment and materials.

△Overall view of single beam laser head

Eylon revealed that 3DM had no plans to become a component manufacturer. Instead, the company will operate primarily as an additive manufacturing hardware provider, although it also sees itself as an application development consultant, as it will work closely with customers and end users to develop materials and applications for its laser powder bed fusion platform.

to hope that finally With 3DM solutions integrated into its production portfolio, Eylon recommends joining the company’s Strategic Partner Program and pre-ordering its single-beam head machines. He said: “As the first batch of production units will be limited in number and we have high demand for these units, we encourage manufacturers who want to stay at the forefront of technology to work with us and join the strategic partnership program to understand the potential for them. Offer benefits on a case-by-case basis and place orders to secure equipment for next year. »

Since hitting the market earlier this year,3DM and its unique products have attracted interest from many industries, including consumer products, medical, automotive and defense. There is also strong interest in additive manufacturing services and there is no doubt that the company promises not only a wider range of materials, but also higher quality parts, faster production speeds and more cost-effective 3D printing . The company’s focus on high-volume production (part numbers in the hundreds of thousands) is also key to its market positioning.

3DM has worked with many end users to develop applications, materials and refine its 3D printing technology. Eylon explains: “We are constantly working with end users and valuing their feedback. We plan to implement changes primarily related to the quality of results, then those related to user experience. Our goal is to build systems of additive manufacturing production which represents a huge but exciting challenge.

According to reports, in terms of applications,3DM companies are more eager to explore use cases requiring specific materials in order to take advantage of the tunable wavelengths of QCL systems. “The most interesting opportunities are those that requirepolymers to achieve their specific applications. We have a few confidential examples and we are always looking for more. “

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.