High-resolution 3D printer (1): The ultimate guide

High resolution 3D printer (3): The highest resolution resin 3D printer

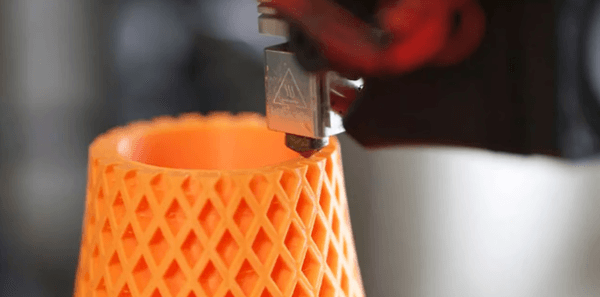

Modeling of molten deposits(FDM) 3D printing can print layer lines thinner than a human hair (Source: Kimya)

3D printingThe machine uses continuously extruded filament in the XY plane, so XY resolution is a measure of the precision of the horizontal movement of the printer mechanism. However, this measurement is not typically listed on industrial-grade FDM printer datasheets, so the only widely used resolution measurement for this technology is Z or layer height.

The precision isA more common measurement in FDM 3D printing, this is an indication of XY resolution rather than a measurement of it.

Dimensional accuracy figures on 3D printer datasheets (e.g. +/- 0.2 mm) are usually derived from test printing and measurements. For example, the UltiMaker Method Series FDM’s +/- 0.2mm dimensional accuracy comes from printing a set of models multiple times on multiple machines and then using a scientific measuring machine to measure the dimensions of each part and compare them to the CAD dimensions. middle model.

Since the height from the ground appears to beThe only resolution measurement widely used in FDM 3D printers, so the lower the layer height, the higher the resolution of the part. It’s simple, is that really the case?

Yes, the layer height is the resolution (it’s even called the layer resolution), but there’s probably no reason to go lower than50 microns, although some printers have layer heights of 10 microns. Similarly, the thickness of human hair is around 70 microns.

Today, various consumers and professionalsFDM machines can all achieve a resolution of 50 microns, which has prompted printer manufacturers to shift their focus from resolution to other metrics that differentiate their machines, such as the precision of Swiss watch mechanisms (stepper motors). pitch, belt teeth, gears, etc.) to control printing. . This results in high accuracy, often called position resolution, as mentioned above. Some printer manufacturers never even mention layer height.

In fact, the impactMany factors influence the achievable layer height in FDM printing, such as material, temperature, nozzle size, environmental vibration and of course software settings. A qualitative comparison of layer height is therefore not very useful.

Instead, layer heights must be precisely matched.

Unlike most resin technologies,FDM slicing software such as Cura and PrusaSlicer offer the ability to change layer heights throughout the printing process. The software will apply smaller or larger layer heights depending on the characteristics of the model. For example, the layer height will become smaller for more detailed parts and larger for featureless parts.

if you need10 micron resolution, you may want to consider upgrading to other technologies.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.