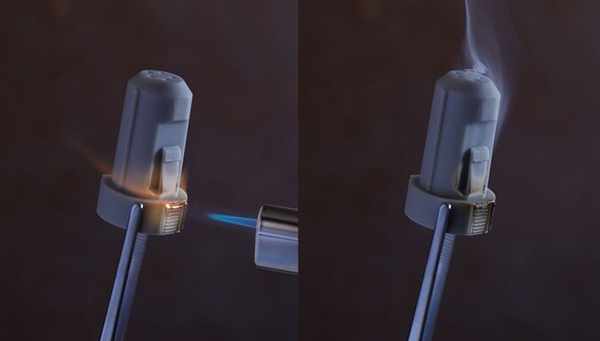

According to the Merriam-Webster dictionary definition, fire-retardant materials areMaterials “manufactured or treated to resist combustion”. In other words, flame retardant materials help maintain normal operations in the event of a fire, while flame retardant materials actively prevent the spread of fire. In 2022, the market value of these materials was 8.63 billion euros, and they are used in various fields such as furniture, textiles, electronics and even construction. Their importance in additive manufacturing is also growing, especially for final parts presenting a fire risk. There are several solutions on the market, including filaments, resins, and powders for 3D printing, and we’ll take a closer look at these options in the list below.

A,filamentThread

High performance materials

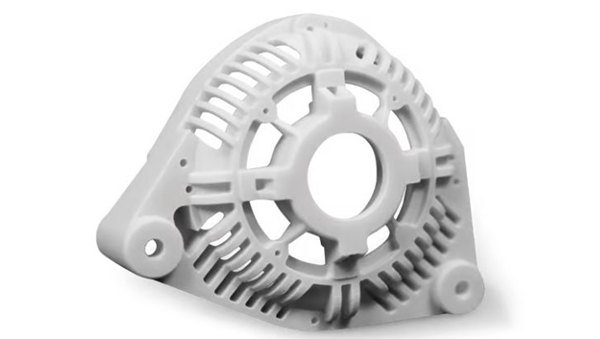

High-performance materials represent a group of polymers capable of withstanding harsh environments, both in terms of temperature and mechanical and chemical stresses. These materials feature complex thermal profiles and are commonly used in industrial applications, primarily in the aerospace, automotive and rail sectors. They are often inherently flame retardant.

if we belongThe PAEK series starts with PEEK which, in addition to its high mechanical and chemical resistance, also has a high flammability temperature. There are many manufacturers of PEEK in filament form, among which we can particularly cite Victrex, Evonik, 3DXTech, etc. We can also mention PEKK, a flame-retardant material that does not emit toxic fumes. It is a polymer very resistant to abrasion and liquids. Finally, when we talk about PEEK and PEKK, it’s difficult not to mention PEI (or ULTEM). Thermoplastics are also flame retardant. Additionally, ULTEM™ 9085 is certified for low fire, low smoke, and low toxicity (FST) applications and has a flammability rating of UL 94 V-0.

Always in high performance materials,PVDF (polyvinylidene fluoride) is flame retardant. It is known for its extremely high chemical resistance and low coefficient of friction – it is particularly popular in the production of nuts, screws, etc. As for manufacturers of filaments for additive manufacturing, Nanovia and Solvay offer PVDF.

Finally, we can usePPSU, which in addition to its interesting thermal properties, is also known for its extreme resistance to hydrolysis, water and shock. The BASF Forward AM brand offers PPSU filament for 3D printing, ideal for the aerospace industry.

to use3D printed parts of the PPSU (Photo credit: Zortrax)

Polycarbonate (PC)

polycarbonate(PC) is a thermoplastic that stands out for its transparency, which is why it is called a glass-like material. In addition to this unique property, it offers excellent robustness, resistance to impact and abrasion as well as mechanical resistance up to 140°C. It is inherently flame retardant and able to withstand repeated steam sterilization. Its resistance remains high even at temperatures as low as -20°C. Polycarbonate is commonly used as a filament for 3D printing in several fields, particularly for the manufacture of prototypes. Their applications include the production of automotive headlights, construction components, castings and translucent housings for electrical equipment. As early as 1958, the German company Bayer introduced industrial polycarbonate to the market. Today, the material is available from several manufacturers, including Polymaker, Kimya and UltiMaker, reflecting its growing popularity and utility in many industrial and manufacturing fields.

Photo credit:3djake

Other flame retardant materials

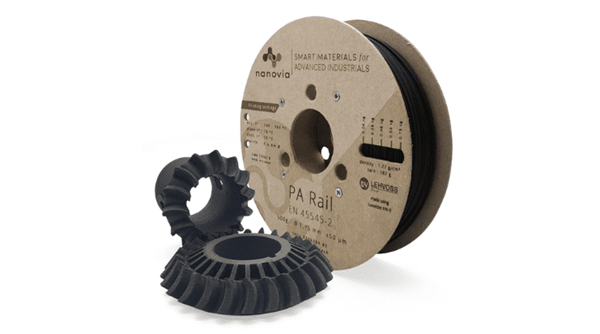

althoughABS and polyamide (nylon), two popular thermoplastics widely used in 3D printing due to their strength and versatility, are not inherently flame retardant. However, it can be made flame retardant by modifying it and adding certain specific additives. There are flame-retardant ABS filaments on the market, such as 3DXTech’s Fire FR-ABS, which is made from high-quality flame-retardant ABS and is UL94 V-0 rated, meaning it has excellent strength to the fire. This type of filament has self-extinguishing properties, making it ideal for applications in areas such as automotive or aerospace. Likewise, PA Rail Nanovia polyamide filaments meet non-flammability standards and are designed to meet the requirements of the railway industry. The filament is made of polyamide (nylon) and flame-retardant ceramic, which prevents the spread of flames and ensures safety in the event of a fire.

Photo credit:Polyfab3D

two,ResinFlame retardant material

Formlabs flame retardant resins

A flame retardant resin is usedSLA (stereolithography) technology is an efficient and inexpensive solution for manufacturing self-extinguishing components. The resin is designed to withstand high temperatures without spreading flames in the event of a fire, providing a solution for industries with strict standards such as aerospace, aviation, electronics and medicine. By meeting the UL 94 V-0 standard, safe and reliable parts can be produced even in industrial environments with high temperatures and near fire sources. After post-treatment at 80°C for 120 minutes, the parts reached a load deformation temperature of 111°C at 0.45 MPa, ensuring their long-term strength and functionality.

Photo credit:form laboratories

Flame retardant materialEPX86FR

EPX 86FR is a flame retardant resin developed by the manufacturers of Carbone. It is characterized by its robustness and durability, offering a viable solution in demanding environments. It is self-extinguishing and BlueCard certified, meeting the strictest fire safety standards. Additionally, EPX 86FR effectively resists high temperatures, thermal shock, chemicals and humidity changes without affecting its basic mechanical properties. This resin can be used in various fields where toughness, fire resistance, precision and surface quality are the basic criteria. Therefore, this material is widely used in industrial, consumer goods and automobile industries. Examples of practical applications include the manufacturing of electronic enclosures and racks, connectors and cable ties.

Photo credit: Carbone

Evolution FR Room

Cubicure Evolution FR is the first product of its type to receive a UL94 V0 rating, making it an excellent choice for industries such as electronics and transportation. This material offers exceptional precision and surface quality while being heat resistant up to 80°C. Cubicure Evolution FR enables precise 3D printing with resolutions up to 10 µm. The first flame-retardant photopolymer for resin 3D printing, it represents a solution for the production of spare parts and functional prototypes. Its UL94 V0 rating ensures that the flame will automatically extinguish in just 10 seconds, a feature previously reserved for materials used in extrusion and laser powder bed fusion processes. Thanks to its halogen-free composition and compliance with the strictest safety standards, Cubicure Evolution FR is positioned as the first choice for industrial 3D printing, particularly in applications where flame retardancy is critical.

Photo credit:In the room

Resin3955 HDT280 TVN

Developed by Loctite3955 HDT280 FST flame retardant resin has very good physical and surface finishing properties. As a high-performance halogen-free material meeting UL94-V0 standards, it is ideally suited for the additive manufacturing of connectors, clips, sockets, electronic enclosures and interior parts in the most demanding industries. Thanks to its performance in vertical combustion tests, the resin is fully compliant with FST aerospace standards, ensuring the safety and reliability of manufactured parts. Therefore, parts 3D printed with this resin (mainly through industrial DLP technology) will not warp in harsh thermal environments. This paves the way for its use in areas such as aerospace and railways.

three,powderFlame retardant material

Flame retardant materialPA 2210 EN

Highly flame retardant polyamidePA 2210 FR is a high-performance UL Blue Card certified and CS/FAR 25.853 compliant material for use in a variety of applications across multiple industries. This halogen-free and therefore non-toxic material has advanced mechanical properties, with a tensile strength of 46 MPa and a flexural strength of 65 MPa. PA 2210 FR offers greater design freedom for complex parts and the ability to manufacture large components, while its 0.15mm layer thickness ensures faithful reproduction of intricate details and precise features. Its low flammability makes it a particularly relevant choice in environments where fire protection is a priority, particularly in the construction, transportation, aerospace and electronics sectors.

Image source:Come to fruition

DuraForm® FR 100 flame retardant material

DuraForm® FR 100, a flame-retardant thermoplastic from 3D Systems, is a solution developed to reduce the production of smoke and toxic byproducts during combustion. The material is UL94 V-0 compliant and meets the strictest environmental standards for a variety of consumer applications. Available in powder form, the material has high toughness and good impact resistance, making it ideal for 3D printing, particularly Selective Laser Sintering or SLS. DuraForm® FR 100 is designed to meet the needs of the aerospace, automotive and consumer product industries requiring fire resistance and low smoke toxicity. It can therefore be used to make aircraft cabins, household appliances, drones and chests.

Photo credit:3D systems

Source: 3dnatives

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.