Recently, Mohou.com learned thatgenerative expression of HPThe 3D text AI model platform 3D Foundry will launch to the public in early 2025, with a planned launch in the first quarter, and 3D Foundry will be browser-based and free to test at launch.

to useFox 3D model generated on demand by 3D Foundry (Source: All3DP)

3D Foundry is based on a generative AI chain, using a text-to-text, text-to-image and 2D-3D image model, then optimizing the 3D printing model through a computational process – this is the goal of the system. . The text-to-text conversion process is trained to create longer (“maybe 500 words”) 2D image generation prompts, while the 2D text-to-image process is based on existing third-party AI models and personalized training data. In the future, Kaiser said he hopes the software will be able to use a variety of generative AI models and allow users to choose styles between them. Currently, the prompt returns four 2D images of the same style, and the user can choose between them for the next generated link.

Kaiser explained that HP2D to 3D systems work by mimicking photogrammetry processes such as 3D scanning. Based on the user-selected image, the system estimates the depth, which Kaiser describes as the “base layer” of the process. The software then creates new 2D images to fill in this depth and find “successful pairs”, ultimately generating a 3D model.

The app is not without its problems. In our demo, the system got stuck at99% generation speed because there is so much fine, hair-like detail, Kaiser said. The first and second attempts produced better results.

From there, users can add texture bases to their models and send them to3D printing service, or download it as an MJF file.

HP3D design supervisor Pierre Kaiser presents a 3D foundry model made by his 6-year-old daughter (Source: All3DP)

3D Foundry’s results are impressive, but HP isn’t shying away from its limitations: Arvind Rangarajan, global head of software and data for personalization and 3D printing at HP, recently told All3DP that they were keen to AI expectations are realistic, while not overpromising.

Kaiser says the software is very good at generating convincing organic shapes, but not at precise measurements, which are crucial for creating functional parts. The solution lies in procedural design: hard-coded designs and constraints that make it easier to generate application-specific models. The keys areAn example shown on Formnext where the basic keys were conformed to a specific design and used as the basis for a 3D model. Other applications are being developed behind the scenes and 3D Foundry will launch a variety of programmatic designs, including generating bas-relief designs for iPhone cases and much more.

When asked if users would be able to input their own calculated design parameters,“I would like to have hundreds of these systems and I would like customers to be able to provide their own output formats,” Kaiser said. “It’s a plan, but it’s just not being implemented yet.”

behind the scenes,The Kaiser team is creating application-specific AI models for its partners, so it appears there is room for growth.

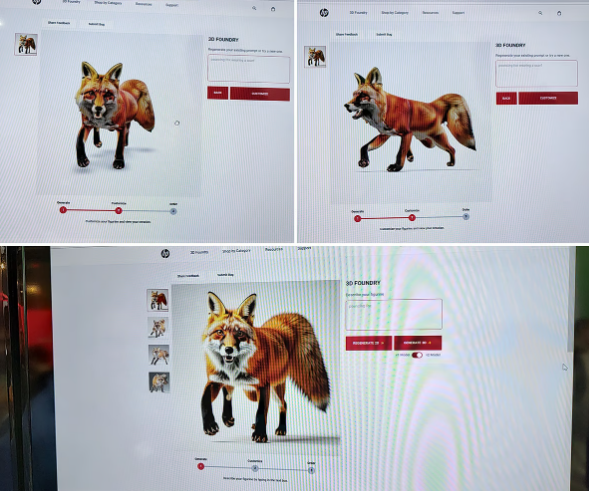

That doesn’t mean you can’t do it without using programmatic design.Functional design in 3D Foundry. An example of the tool’s potential is the body of the drone, made of hollow tubes and lightweight. Brian Ingold, director of 3D solutions at HP, said it took some prompt-based experimentation, but it ultimately worked.

to useLightweight drone model generated by HP 3D Foundry (Source: All3DP)

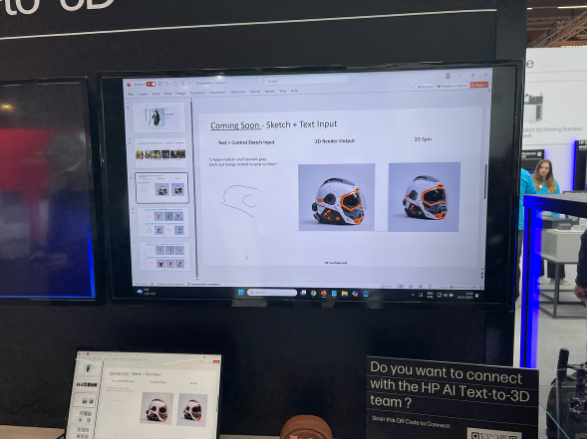

More detailed features will be available soon. In the roadmap demo,Kaiser presented the model generated under the “Control Image” constraint, a simple sketch: first a headset, generated from text prompts and a minimal sketch; then a more detailed sketch of the character, ultimately resulting in brightly colored cartoon models.

Achieved Using Text Prompts and Minimal Sketches3D helmet model generated by HP 3D Foundry (Source: All3DP)

3D Foundry is currently focused on organic, ready-to-use products (as evidenced by Formnext’s interactive demos), with professional models already actively used by some HP 3D partners. The final step is to implement restrictions to generate protected intellectual property to ensure that 3D Foundry complies as closely as possible with legal requirements.

If all goes well,3D Foundry will be a constantly evolving application. Kaiser said he has a three-year plan for his team, and it just depends on how much funding they can get after launch.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.