3D printing parts is not as simple as pressing a button on a 2D printer. You have to prepare the model, make sure the printer is correctly configured to avoid errors and defects, choose the right materials, etc. In most cases, post-processing also plays a role: once a machine has completed its journey, it usually must go through stages such as cleaning, depowdering, annealing, heat treating and even smoothing, painting, staining, etc. Depending on the printing technology you choose, there will be more or less. For example, with photopolymerization processes, 3D printed parts must be cleaned after printing to remove excess non-photopolymerized resin, and must also be cured to give the material its full properties and prevent distortion. For this, the user must be equipped with a suitable solution, generally provided by a 3D printer. There are many machines on the market: some are automated and suitable for industrial use, others are office machines suitable for any working environment. In the following article we will focus more on the second category. Cleaning and curing solutions for stereolithography 3D printing are listed alphabetically by manufacturer name.

3D and UV systems Figure 4 350

The 3D Systems Figure 4 350 UV Curing Unit is sold separately from the Figure 4 Modular System, but is ideal for parts over 200mm in height made with this solution. It is intended for curing only and is capable of curing parts up to 350mm in height, the maximum part height on the Figure 4 modular system, or curing multiple parts simultaneously at a multi-rack level. User guides provide all the necessary information for each resin type, ensuring the highest quality finish.

Photo credit:3D systems

Cleaning and Curing Anycubic 3 Plus

Anycubic can be said to be one of the most popular desktop resin machine manufacturers in the international market. It develops its own cleaning and curing solutions and offers a range of products ensuring that post-processing steps are carried out on the same machine. Wash&Cure 3 plus has a capacity of 8.4 liters, 25% more than its sister product. Concretely, the cleaning tray measures 230 x 140 x 260 mm. The post-processor is equipped with a double platen to harden the 3D printed parts: this part is produced using a new gooseneck lamp, which increases the energy value and offers maximum areas of detail . Finally, note that the machine is easy to use thanks to the touch screen which allows quick selection of its modes – cleaning, hardening, light activation, etc.

ApexMaker Solution

The ApexMaker UV Resin Curing Light and ApexMaker Clean Platform Workstation are designed to optimize post-processing of resin printed parts. The ApexMaker UV resin curing lamp uses a UV lamp with six high-power 405nm LEDs and is suitable for parts printed with LCD, DLP or SLA technology. The lamp can cure 3D parts in just a few minutes, and the manufacturer claims that no resin remains after curing, adding to the strength of the part. It is also equipped with a 360° turntable system at 10 revolutions per minute to rotate parts for even curing. The ApexMaker Cleaning Platform is a cleaning station with a 50 liter drum and models with a maximum capacity of 400 x 380 x 280 mm. These dimensions help simplify the cleaning process for larger models.

ApexMaker machine (Photo credit: ApexMaker)

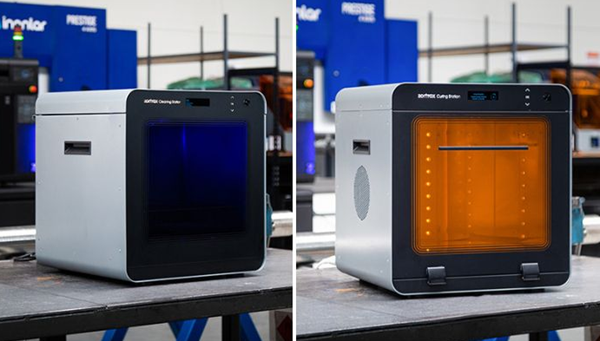

Suitable for industrial grade partsatum3DSolution

Based in the Netherlands, atum3D aims to take DLP technology to the next level. One of the post-processing solutions offered is a parts cleaning station, which relies on the cavitation effect produced by high-frequency shock waves (ultrasound) in ethanol. The machine has a stainless steel housing and basket and is capable of digitally adjusting the washing power and frequency. Additionally, atum3D offers an industrial-grade annealing station that combines powerful 45-watt UV light with radiant heat built into the vacuum chamber for superior performance. The quenching station has a capacity of 282 x 395 x 275 mm, allowing the processing of large parts, increasing speed and helping to optimize precision and final performance.

Photo credit:atum3D

Creality UW-02, an all-in-one large format printer

Creality’s UW-02 is an all-in-one cleaning and curing solution designed for large rooms. It allows parts up to 25 cm to be aggregated (aggregation volume 200 x 200 x 300 mm). Some cool features include 360° curing (using a rotating platform) and dual-band 385nm and 405nm LED beads. Creality also claims that the machine will deliver more powerful cleaning thanks to its large custom magnetic fan and customizable wash speed and duration of 2/5/10/15/20/30 minutes (fast or medium). The size of the wash is 250 x 160 x 200 mm.

Image source: Creative

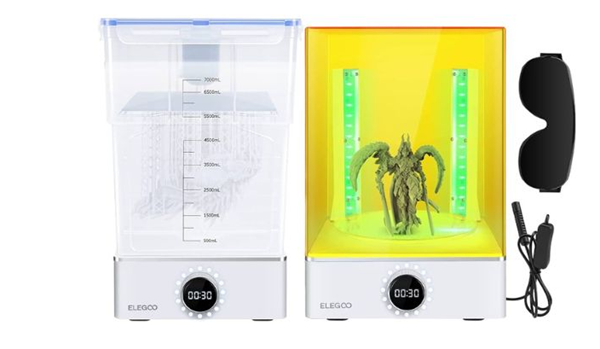

ELEGOO Mercury

Supplied by the Asian resin 3D printer manufacturer of the same name, the ELEGOO Mercury XS printer contains a cleaning station and a curing station for dual cleaning and curing of parts. Like the other solutions mentioned in this list, it offers 360° exposure via two adjustable L-shaped light bars and four additional LED lights placed under the turntable. When curing, it emits ultraviolet light with a uniform wavelength of 405nm for uniform exposure from all angles. The maximum station size is 200x260mm. Handheld UV lights can also inspect the interior and corners of 3D printed parts. The cleaning station is equipped with a large capacity sealed water tank (7 liters), which allows cleaning large rooms or cleaning in batches. If you want to clean the part without removing the build plate, the maximum cleaning size is 180 x 121 x 153 mm, or 201 x 124 x 255 mm without removing the build plate.

Photo credit:ELEGOO

EMAKE3D Cleaning and Curing Solution

EMAKE3D offers cleaning and curing solutions in different sizes: the annealing station measures 400 x 400 x 400 mm, while the cleaning machine is smaller (385 x 385 x 250 mm). The latter has two rinsing speeds, slow and fast, as well as a time setting allowing you to clean a room in three to twenty minutes. The machine is simple to use and can be interrupted at any time.

The wavelength of the solidifying solution is403 nm, with a power of 120 W, it can quickly process prints in five to ten minutes. Time settings allow users to cure prints based on specific resin characteristics. The 360-degree platform ensures prints are cured in all directions, while three independent sets of LED curing lights provide even illumination. Each lamp has a lifespan of over 20,000 hours.

Image source:EMAKE3D

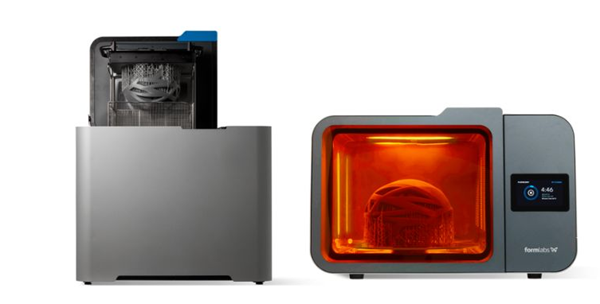

Formlabs and Wash L and Cure L from Formlab

Formlab’s Wash L provides users with smooth, clean parts and automates processes to provide the best user experience. Once cleaning is complete, remove the parts from the solvent and air dry them to avoid over-soaking the print. Additionally, a built-in solvent monitor tells the user when to change solvents. This cleaning machine is only compatible with Formlabs SLA 3D printers: users can use the included bed adapter to clean one Form 3L bed or two Form 3s simultaneously.

Formlabs Cure L enables 3D printed parts to achieve maximum mechanical performance and optimal dimensional accuracy. The machine is equipped with two 500 W heaters and a very powerful UV lamp in a reflective interior chamber which cures parts in less than 10 minutes. The dial ensures uniform exposure. Like Wash L, Cure L is optimized for Formlabs materials and comes with pre-programmed settings for the manufacturer’s resin. With dimensions of 690 x 540 x 445 mm, the Cure L is a large machine.

Wash L (left) and Cure L (right)

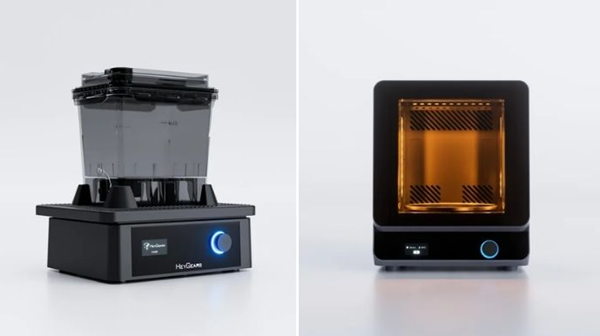

HeyGears and their cleaning and curing solutions

The UltraCraft Cure and UltraCraft Wash stations are complementary tools designed to optimize the production process of the Reflex and Reflex RS ranges from the manufacturer HeyGears. UltraCraft Cure guarantees complete curing from any angle with its dual UV wavelength technology. In addition, it also has an automatic calculation ofAdvanced features include curing time, an additional heating system and two curing modes that can be adjusted to the user’s needs. The UltraCraft Wash, on the other hand, stands out for its vibrating cleaning system which increases efficiency by 15% and allows for deep cleaning with minimal contact with the resin. Together, these workstations ensure high-quality end results and a streamlined production experience.

Photo credit:Hi Gears

MeccatroniCore machine

The BB CURE N and BB Wash workstations are advanced solutions for post-processing resin 3D printing. BB CURE N accelerates curing via an inert gas system, increases UV penetration to 3mm and ensures biocompatibility via a certified workflow. The BB Wash, on the other hand, makes cleaning easier thanks to its double baskets, its efficient rail system and its non-flammable liquid alternative to IPA. It works via WiFi or Ethernet and stores detailed reports for overall process control. Together they provide a professional workflow.

BB CURE N station (left) and BB WASH station (right)

Nexa3D cleaning and curing solutions

Nexa3D also offers post-processing solutions for office and industrial printers. For example, the Clean+Cure Station is a two-in-one post-processing station designed to simplify finishing resin 3D prints. It is compatible with XiP printers and most resin 3D printers. Its 5.5 liter capacity allows parts to be immersed in IPA or xCLEAN solutions for cleaning, while its magnetic stirrer ensures even cleaning. For curing, it features a rotating base that exposes parts evenly to light, and comes with adjustable LED arms and reflective covers. Therefore, this tool is ideal for those looking for professional results in a compact and convenient package.

Photo credit:Nexa3D

Photocentric and its range of post-processing solutions

Photocentric is well known in the 3D printing industry for its resin 3D printers and in particular its range of LCD machines (Opus, Magna, Titan). In addition to these additive manufacturing solutions, it also offers post-processing stations for resin parts. Although it offers different stations depending on the printer used, here we will only consider the Wash XL and Cure XL, both designed for large format models. The first is a 3-in-1 option that effectively cleans, rinses and dries large and complex 3D printed parts. The second is a machine that uses dual wavelength light to ensure uniform curing of large parts. In addition, thanks to the 360° rotation of the platform, the heat is distributed evenly, resulting in precise, non-stick pieces.

Image Source: Focused on Light

Phrozen and its cleaning and hardening station kit

The Phrozen Cleaning and Curing Station kit provides a complete system for cleaning, drying and curing large resin 3D prints. The washing station measures 277 x 207 x 467 mm and the drying station measures 354 x 309 x 368 mm. The cleaning capacity is 8 liters and can handle models up to 218 x 123 x 235 mm. The manufacturer recommends using it first for 3D prints made with the Phrozen Sonic Mighty 8K resin printer. Equipped with a powerful turbine for gentle cleaning and 405nm UV light to ensure even and efficient curing. According to the manufacturer, the cleaning station effectively cleans models without damaging their details. The dual-fan drying system prevents surfaces from sticking, while its compact design allows it to be used even in tight workspaces.

Image source:Phrozen Technology

prusaCW1S

Prusa CW1S is a multifunctional machine that integrates four functions: preheating, cleaning, drying and UV curing to optimize the post-processing process of 3D resin printed parts. The dimensions of the solution are 218 x 232 x 345 mm. The preheat function brings the resin to the ideal temperature for high quality printing, especially for the SL1S machine. For cleaning, the CW1S uses a stainless steel water tank and a magnetic turbine that creates a gentle vortex that helps remove residue without damaging details, even for the smallest 3D prints. After cleaning, the model is dried to prevent resin staining and prepared for the final UV curing stage, essential to impart optimum strength and surface properties. Four 405 nm UV LED strips ensure uniform curing with a power of 52.8 W. The machine is also equipped with a smart infrared sensor that detects the presence of a tank and adjusts the available options, making operation more intuitive .

On the left isCW1S (left), with the machine and its components on the right (photo credit: prusa)

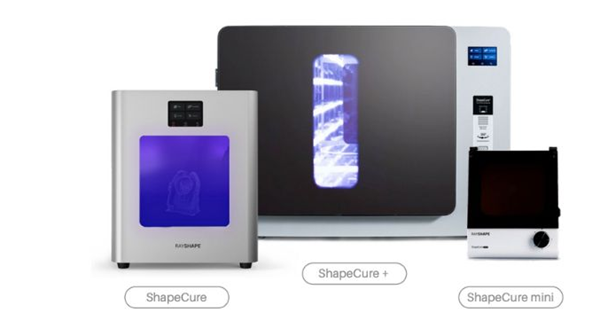

Rayshape ShapeCure and ShapeWash Series

Rayshape offers a range of systems for cleaning (ShapeWash) and curing (ShapeCure) resin prints. The ShapeWash 020S and 040S machines are compatible with the use of alcohol and isopropyl alcohol (IPA) as cleaning solutions. They come with stainless steel baskets and use ultrasonic cleaning. The two models are designed for different applications: the 020S is more suitable for small rooms and small volumes, while the 040S is suitable for larger rooms or high volumes. The ShapeCure series for curing resin prints uses multiple LEDs arranged around a 360° rotating platform that supports the part for increased power and curing efficiency. The ShapeCure solution is particularly capable of handling full-sized models. There are also mini and ShapeCure+ versions for small or large models.

Manufacturer’s cleaning and curing solutions (photo credit:Ray shape)

SinceFabWash and FabCure 2 from Shining 3D Dental

These cleaning and hardening solutions are made by dedicated dentistsDeveloped by 3D printing manufacturer brand Shining 3D Dental. These solutions allow complete, simple and automated post-processing of 3D printed resin parts by professionals (dental clinics, dental technicians, etc.).

FabWash is pre-programmed for each material and has an automated part demolding, cleaning and drying process. The machine has a capacity of 9.5 liters and uses a magnetic turbine for cleaning. As for the FabCure 2 Curing Station, it offers high-power multi-surface curing, rapid chamber heating, custom curing settings, and simple operation with an OLED display via 30 x 70W LEDs. The manufacturer recommends these stations as standard post-processing tools for Shining 3D printers.

Photo credit: Brilliance3D

SprintRay ProWash S and ProCure 2

SprintRay provides an innovative ecosystem of 3D printing solutions for dentistry. Its ProCure 2 post-curing system and ProWash S cleaning system are designed for speed and thoroughness. With ProWash S, 3D printed parts are cleaned in two steps and then dried in three steps. The ventilated mechanical nozzles provide powerful drying capabilities, so the entire working process of this machine lasts only nine minutes. The pieces are carefully cleaned and dried before hardening.

For this step, it is recommended to useSprintRay’s ProCure 2 also stands out for its speed because it does not require a long preheating time and generates heat directly. Specifically, ProCure 2 uses heat and light to achieve superior final mechanical properties on 3D printed parts. The light generator ensures uniform curing of each part, with the 385nm beam emitting targeted heat. All machines (printers, cleaning and curing solutions) can be connected together, allowing a complete workflow.

Photo credit:SprintRay

Suitable for resin technologyStratasys post-processor

Stratasys is one of the leaders in the additive manufacturing market. Among the different technologies it offers, we find resin-based technologies such as PolyJet, P3 or stereolithography. As with any resin-based process, additional post-processing is required to achieve optimal results. The manufacturer offers two solutions designed specifically for cleaning and curing 3D printed parts. First there are the PolyJet cleaning stations (CSIIP and DT3). CleanStation CSIIP uses an alkaline cleaning solution to quickly dissolve excess material, while CleanStation DT3 uses a water jet to quickly dissolve soluble support materials in printed parts and models. For part curing, Stratasys offers Origin Cure, a machine designed to ensure the precision, repeatability and detail of parts printed with Origin 3D printers. To this end, 360-degree LED curing, multi-wavelength curing and high-intensity curing ensure uniformity and preserve complex design elements.

Image source:Stratasys

Ultrasonic cleaning machines andRC-2

The SUNLU ultrasonic cleaner is an affordable option with multiple speed options and time control. Featuring three cleaning intensity speeds and a 2.7L capacity to accommodate bulky items. Using a photoresist cleaner, users can clean resin models, but the machine can also be used to clean non-printed parts such as glasses and jewelry.

The RC-2 UV Resin Curing Box is an equally cost-effective option for curing resin parts. Once the user has cleaned the print, it can be placed in a drying box to dry and harden. Using patented air duct technology, the machine allows prints to dry faster and the internal fan has three speeds. The machine offers a drying space of 200 x 200 x 250 mm and is equipped with 20 UV lamps. Four UV lamps are placed at the top, four at the bottom and twelve at the sides, with a maximum power of 42 W evenly distributed.

Image source:SUNLU

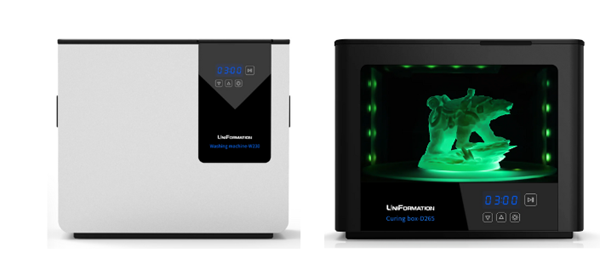

UniFormation and its cleaning and curing solutions

UniFormation offers a complete solution for the post-processing of resin 3D prints, one of which is dedicated to cleaning and the other to curing: UniFormation Ultrasonic Resin Cleaner W230 and UV Resin Curing Station 10.2

The W230 ultrasonic cleaner has a capacity of 6.5 liters and a cleaning volume of 228 x 128 x 200 mm. Uses 40kHz ultrasonic technology to remove resin without affecting detail. Models can be cleaned directly on the work surface inside the fine mesh basket, ideal for working with smaller parts. Due to its small size (382x202x330 mm), it is compatible with most DLP/SLA printers on the market.

The 10.2 UV resin curing station is a curing station with a working volume of 260 × 160 mm, using 16 evenly distributed UV lamps and equipped with an automatic turntable. It also features a flip lid and a touchscreen, allowing users to access intuitive presets such as a 3-minute timer. It is compatible with LCD/DLP/SLA 3D printers and is suitable for creating various objects such as jewelry, dentures and industrial prototypes.

UNIZ U Wash and U Cure

According to the manufacturerAccording to UNIZ, U Wash uses ultrasonic technology to ensure fast and effective cleaning, removing uncured resin in just six minutes or two wash cycles. U Wash’s ultrasonic technology has a frequency of 40,000 Hz and a power density of up to 2,500 mW/cm². The 2 liter stainless steel tray holds water or isopropyl alcohol. U Wash has no moving parts, making maintenance quick and easy.

on the other hand,U Cure is a curing station that only takes a minute to complete its process. UV energy density is 120,000 mJ/cm² and uniformity is 90%, enabling non-stick surfaces. Multi-directional UV LED systems and multi-angle reflectors allow 3D printed models to be placed anywhere on the work surface. Both devices feature the same compact design, measuring 280 x 280 x 250 mm, and feature a touchscreen.

Photo credit:UNIZ

Zortrax Cleaning and Curing Solutions

varnish manufacturerZortrax offers two solutions for cleaning and annealing 3D printed resin parts. For cleaning, the Zortrax cleaning station offers a work space of 300 x 210 x 270 mm and an 18 liter dustbin. It is equipped with a turbine so as not to damage the parts and preserve its details. A cycle lasts only 5 minutes: once finished, the lid of the machine is opened and the container is removed from the liquid. The machine’s filter ensures greater safety and allows isopropyl alcohol to be reused over several wash cycles.

For hardened parts, the manufacturer providesZortrax curing station with a working space of 300 x 200 x 300 and a UV wavelength of 405 nm. The chamber uses polished metal panels to provide uniform UV exposure. The machine is completely safe thanks to a soft-closing door and a sensor that immediately turns off the UV light when the door is opened.

To the left is the cleaning station; on the right is the curing solution (Photo credit:Zortrax)

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.