2022Year8moon17day, IndiaLV PrasadEye Institute (LVPEI), Indian Institute of Technology (ITI), in collaboration with the University of Hyderabad and the Center for Cellular and Molecular Biology3DThe printed corneas have been successfully tested on animals.

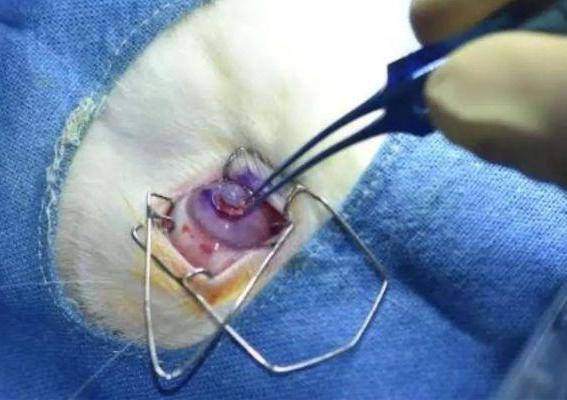

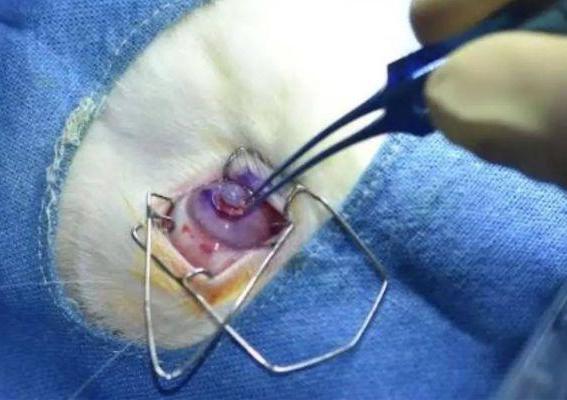

△3DPrinted corneas transplanted into rabbit eyes

The team says this artificial material contains no residual cornea and is made from bioink derived from human donor tissue.3DPrinted corneas transplanted into rabbit eyes. Since the cornea is based on “completely natural “basis, which is why the developers of the corneal implant say it could soon be “for humans“to treat corneal scarring and other serious eye conditions that can lead to blindness.

“LVPEIprincipal investigatorBuy themPhD andVivken SinghThe doctor said:“This is the first time3DOptically and physically printed human corneas suitable for transplantation.“used to do this3DBioink for corneal printing has a wide range of applications, for example for soldiers with eye injuries during war to seal corneal perforations and prevent infections, or in remote areas where it does not exist of specialized ophthalmological centers.“

△The technology is being prepared for clinical trials through translational research

Why study biology3DPrint corneas?

The cornea is transparent in the eye. It covers the iris and the pupil. It is usually elastic and can heal from minor abrasions. However, improper use of contact lenses can cause scarring of the cornea. Even those who lead a healthy lifestyle and take good care of their eyes can fall victim to problems such as corneal dystrophies, which cause blurred vision and are particularly passed on to the next generation.

Although corneal replacements are actively researched worldwide, they are either animal-derived or synthetic. According to the National Eye Institute, the main remedies used to treat corneal diseases remain laser treatment, or the transplantation of organic or artificial tissue. However, even if the prosthesis cannot restore the patient’s vision, cell transplants often come from animals, but the biggest problem is that this method carries a certain risk of rejection and is very unsuitable for some religious countries (such as India, etc.) ).

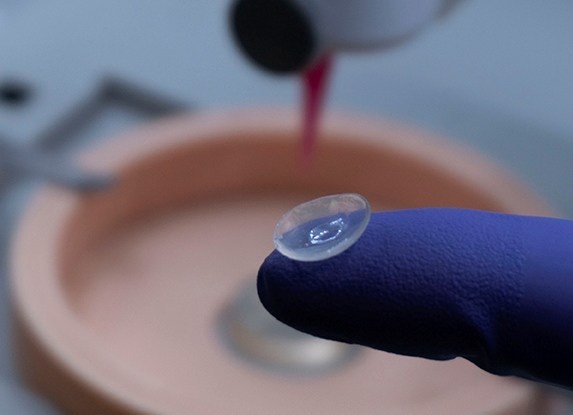

△Pandorum Technologiesliquid3Dbiological cornea

biology3DPrinting technology

To get around cultural and religious issues surrounding the use of certain animals in eye implants, the researchers instead based their study on human tissue donations. Specifically, the team developed a biometric hydrogel using a decellular corneal tissue matrix and stem cells extracted from human eyes.

The material is completely free of synthetic components and is designed to provide an ideal microenvironment for matrix regeneration. Actually,IIT-HyderabadAssociate ProfessorFalguni Pati“This bio-ink can even simultaneously maintain the curvature and thickness of the bioprinted cornea, making implantation easier,” said Dr.

The team said the operation went very well.LVPEIofBuy themPhD andVivken Singh“Bioprinting may soon prove useful in the treatment of eye scarring or conditions such as keratoconus, where keratitis can cause considerable vision problems,” said Dr.

As with other implant development efforts, translational research in preparation for further clinical trials will be conducted bySree Padmavathi VenkateswaraThe fund provides support. The team hopes that this technology will help make corneal transplants more relevant and less expensive in the country.

△Pandorum Technologiesof3DCorneal Stromal Lens Printing

3DPrinting technology has been used to restore vision

Going back further, based in BangalorePandorum Technologiesbusiness, in2019corneal tissue3DBioprinting aims to allow eye injuries to heal seamlessly. At that time, the company3DCorneal stromal lens printing is considered a potential way to treat vision loss caused by corneal disease without the need for human donors.

In a more practical application, IsraelShareMedical Center (SZMC) earlier this year, surgeons successfully performed the world’s thinnest artificial cornea transplant. Depend onYoonDeveloped by the company50A micron-thick implant was used to restore a local patient’s vision, significantly reducing his wait time for surgery.

source:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.