2022Year9moon4day,According to Mohou.com,Washington State University (WSU) A research team has developed a simple and effective method to recover and convert polylactic acid (PLA). This is a way of transforming normally discarded plastic into3DThe advantageous resin method used in printing allows plastic waste to be recycled and reused.

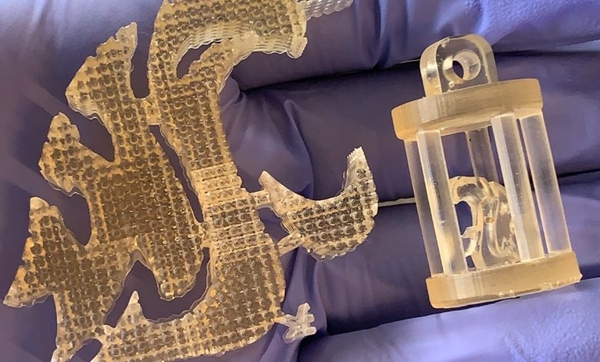

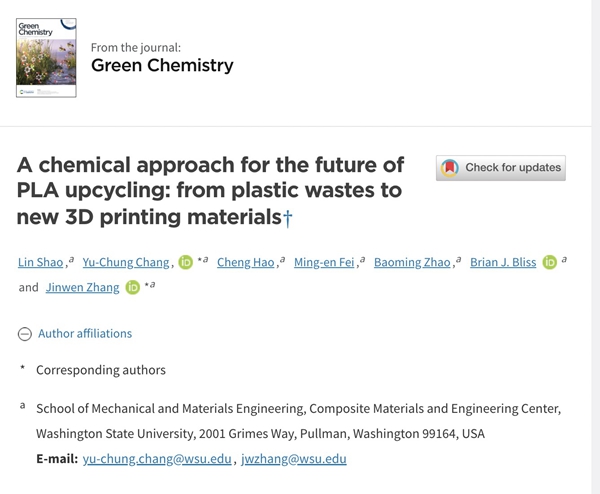

△WSUThe research team uses recycled materialsPLAplastic, made for3DPrinted with high quality resin

Postdoctoral researcher at Washington State University and one of the study investigatorsYu Chung ChangHe said: “We’ve found a way to instantly transform it into something more powerful and better, which we hope will inspire people to ‘improve’ these things rather than throw them away. We made it directly from waste, stronger materials and I believe this technology will provide great market prospects in the future. »

According to the university, the world produces approximately3010,000 tonnesPLAand its use is increasing considerably. Although it is biosourced, it is classified as7plasticPLANot easy to decompose. It can float in fresh or salt water for up to a year without degrading. It is also rarely recycled because, like many plastics, when it is melted and reformed, it no longer performs as well as it originally did and loses its value.

Changexplain:“Although it is biodegradable, once you dig into it you will find that it breaks down in the soil until100For years, in reality, this will still produce a lot of pollution for the environment. We want to solve the problem that when people actually start producing polylactic acid on the million-ton scale, we need to know how to deal with it.

In their study published in the journal Green Chemistry, researchers led by Professor Zhang Jinwen of the School of Mechanical and Materials Engineering developed a rapid, catalyst-free method for recycling polylactic acid by breaking down the long molecular chains into one single unit. The entire chemical process can be completed in about two days at room temperature. Aminoethanol, a chemical used to break down polylactic acid, is also cheap, they explain.

△This converts plastic into3DThe resin printing method can also reduce the pressure caused by the decomposition of plastics around the world.

Changexplain:“If you wanted to turn a Lego castle into a car, you’d have to take it apart brick by brick, and that’s what we did. Aminoethanol precisely cuts polylactic acid into monomers, and once it’s back to monomers, you can repolymerize it into something more powerful.“

Once the polylactic acid was broken down into its basic elements, the researchers reconstructed the plastic and created a photopolymerizable liquid resin commonly used as a3DPrinting supplies for printers. when it is used for3DWhen printed and cured into plastic sheets, the product exhibits mechanical and thermal properties equal to or better than commercially available resins.

Although researchers focus onPLAresearch, but they hope to apply this work to polyethylene terephthalate (PET), which is better thanPLAMore common, they have a similar chemical structure, but pose greater waste utilization problems.

It appears that they have filed a provisional patent application and are working to further optimize the process.

source:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.