Click to learn:List of CNC materials Mohou.com

Today I would like to introduce you to someCNCPlastics have their own characteristics,Helping everyone to better choose the subject that suits them

01.ABSplastic

ABSIt is a general purpose, versatile plastic. It offers high impact resistance, toughness and strength at an affordable price. It is also easy to finish, as it can be easily painted, glued or welded together. If left as is, it will have a matte finish.

advantage:ABSIdeal for general purpose prototypes, preformed prototypes, parts prone to impact and requiring robustness, or where low cost is required.

default:ABSDoes not have good resistance to abrasion or chemicals and will melt in acetone. It’s also not a particularly durable plastic. Also.

Common applications:ABSThe most common application is injection molding, used to make electronic enclosures, household appliances and even the iconic Lego bricks.

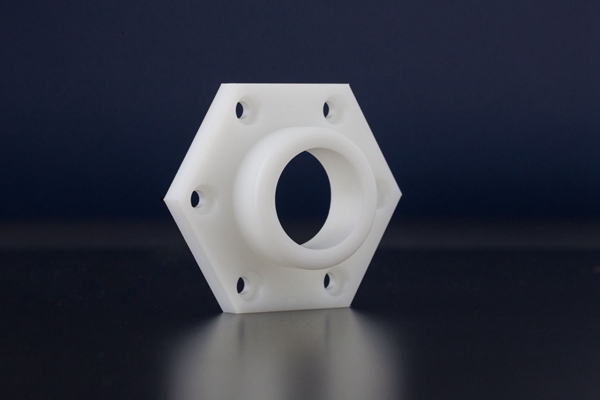

02.nylon

Nylon is a strong, durable plastic suitable for a variety of uses.

Advantages: Nylon has high strength and stiffness, resists over a wide temperature range, has good electrical insulation and exhibits good resistance to chemicals and abrasion. Nylon is ideal for applications requiring inexpensive, strong and durable components.

Disadvantages: Nylon absorbs moisture, causing it to swell and lose some dimensional accuracy. Distortion can also occur if a large amount of asymmetric material is removed during processing due to internal stresses inherent in the material.

Common Applications: Nylon is most commonly found in medical devices, circuit board mounting hardware, automotive engine compartment components, and zippers. It is used as an economical replacement for metals in many applications.

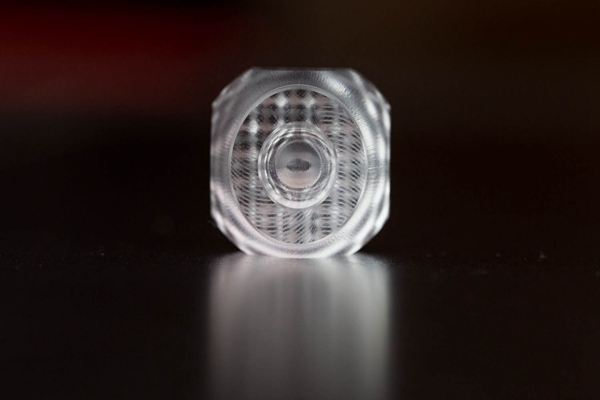

03.PMMA

PMMAThis is acrylic, also known as plexiglass. It is strong, has good impact and scratch resistance and can be easily glued using acrylic cement.

Benefits: It is ideal for any application requiring optical clarity or translucency, or as a less durable but less expensive alternative to polycarbonate.

default:PMMAis a fragile plastic that cracks or breaks rather than stretching. Any surface treatment on a piece of acrylic will lose its transparency, giving it a frosty, translucent appearance. It is therefore generally best to pay attention toPMMAIndicates whether the part should maintain the original thickness to maintain transparency. If the machined surface requires transparency, it can be polished as an additional post-processing step.

Common applications: after treatment,PMMAis clear and most often used as a lightweight alternative to glass or light pipes.

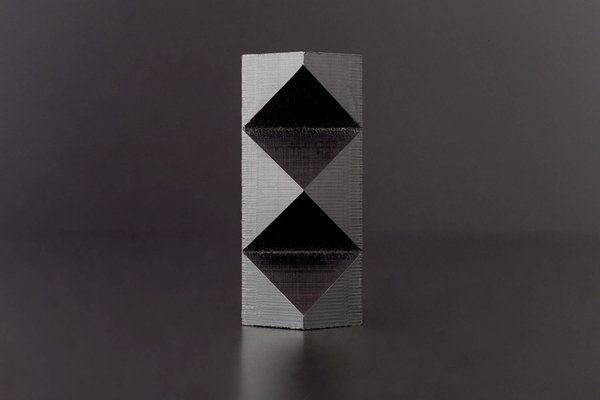

04.POM

P.O.M.is a special brand of acetal homopolymer that features a smooth, low friction surface, excellent dimensional stability and high rigidity.

advantage:P.O.M.is a good plastic for these or any other applications that require a lot of friction, require tight tolerances, or require a high stiffness material.

default:P.O.M.Very difficult to glue. The material also has internal stresses that make it susceptible to deformation in areas that are thin or have significant asymmetric material removal.

Common applications:P.O.M.Typically used in gears, bearings, bushings and fasteners, or in the manufacture of assembly jigs and fixtures.

05.HDPE

HDPEIt is high density polyethylene.

advantage:HDPEIt is a very low density plastic that also has excellent chemical resistance, electrical insulation and a smooth surface. It is ideal for making caps and gaskets due to its chemical resistance and sliding properties, but is also an excellent choice for weight or electrically sensitive applications.

default:HDPEThe main disadvantage is low resistance, especially to stretching and bending.

Common applications:HDPECommonly used in fluid applications such as fuel tanks, plastic bottles and fluid flow tubes.

06.PC

PCIt is our most sustainable plastic.

Advantages: It has high impact resistance and rigidity and remains functional over a wide temperature range. It is also optically transparent and can be dyed black if necessary to be opaque.PCIdeal for applications requiring very hard or tough plastics, or where optical clarity is required. SO,PCIt is one of the most used and recycled plastics.

default: purePCNot very resistant to wear and easily scratched. If desired, scratch-resistant coatings and steam polishing can be added as post-processing steps to improve wear resistance or optical clarity. It also doesn’t have readily available two-inch-thick parts, which limitsPCDimensions of the parts.

Common applications:PCIts durability and transparency make it possible to make optical discs, safety glasses, light pipes and even bulletproof glass.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.