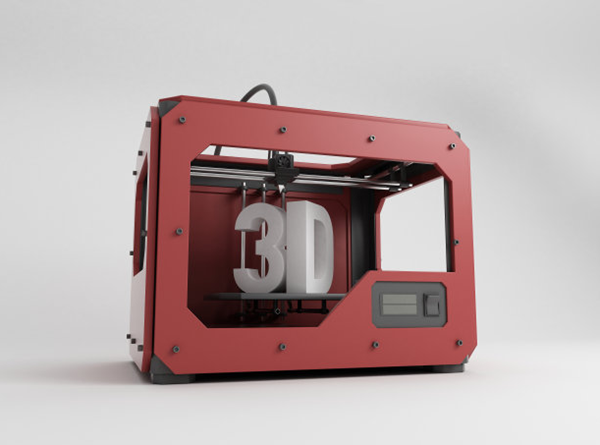

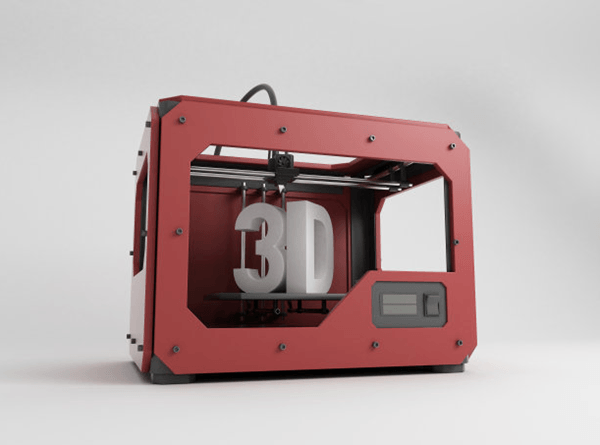

What is 3D printing? What can 3D printing do? What are the advantages of 3D printing products? These are the three questions that many customers who are new to 3D printing want to know. Today I will tell you why you choose 3D printing to print products.

3D printing is a type of rapid prototyping technology, also known as additive manufacturing. This is a technology that uses adhesive materials such as metal powder or plastic to build objects through layer-by-layer printing based on digital model files. 3D printing is usually carried out using digital technology hardware printers.

It is often used to make models in mold making, industrial design and other fields, and is gradually used in the direct manufacturing of some products. There are already parts printed using this technology. The technology has applications in jewelry, footwear, industrial design, architecture, engineering and construction (AEC), automotive, aerospace, dental and medical, education, geographic information systems, civil engineering and other fields.

Advantages of 3D printing:

(1) Product complexity and diversification have nothing to do with cost. Under traditional manufacturing methods, the more complex the shape of the product, the higher the manufacturing cost. At the same time, traditional manufacturing equipment has fewer or unique functions, and the product shapes that can be processed are limited. For a 3D printer, it can print products of various shapes, whether complex objects or simple shapes, without having a big impact on its manufacturing cost. It does not require any machining or prefabrication of molds, which greatly reduces the difficulty of manufacturing complex products and shortens the development cycle.

(2) Manufacturing without skills. Traditional artisans must be apprenticed for several years to master the required skills. Mass production and computer-controlled manufacturing machines have reduced skill requirements, but traditional manufacturing machines still require skilled professionals to adjust and calibrate them. To use 3D printing technology to make similarly complex products, individuals simply need to make an intelligent design on the computer, then convert the complex workflow into digital files and send them to the printer 3D to carry out manufacturing. During the whole process, users do not need to master various complex manufacturing techniques and processing skills, which greatly reduces the technical threshold of the manufacturing industry.

(3) Benefits of personalized customization. 3D printing can realize on-demand production, reduce the company’s physical inventory, avoid the waste of resources of a large number of unsold goods in mass production, and is more environmentally friendly. Even products can be printed nearby and on demand, reducing logistics and product transportation costs.

The above advantages make 3D printing very suitable for rapid manufacturing of the following types of products:

1. Complex structure. Such as free-form surface vanes, complex internal flow channels, etc. which are difficult to treat with traditional methods, and even those which cannot be treated, such as internal hollow structures;

2. Personalized personalized products. Such as personalized production of jewelry, human organs, cultural creativity, etc., small batch production, as well as research, development and manufacturing verification before mass production of products;

It is worth pointing out that from the perspective of the research and application situation at home and abroad, compared with the traditional technology of machining, casting, forging, welding and casting, the 3D printing technology lags far behind the latter in terms of product dimensional accuracy and surface quality. , post-processing is tedious, and the product performance is not as good as many The requirements for high-end metal structural parts; secondly, they are still relatively low in processing speed and mass production efficiency, and cannot fully meet the needs of the industrial field; finally, the cost of 3D printing equipment and consumables is always; high, such as the cost of metal powder printing. Much higher than traditional manufacturing costs.

Therefore, although 3D printing technology is a revolutionary advancement in traditional manufacturing technology, it cannot completely replace traditional manufacturing technologies such as cutting, casting and forging. The two should support and complement each other, and improve and develop a healthy cooperative relationship together.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.