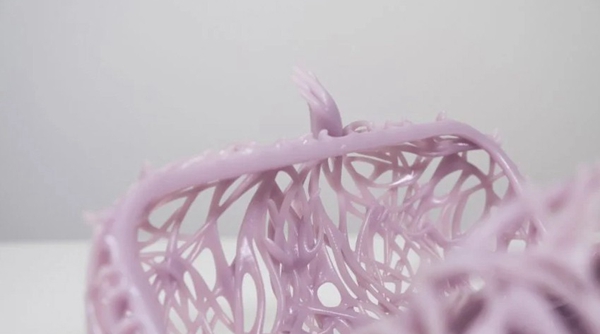

2022Year9moon27Japanese and Austrian designerJulia Koernerfor his fashion brandJK3Dproduced a3DPrinted pouch, this pouch is made from bioplastic. Already at2022YearM.Q.Shown at Vienna Fashion Week, the collection was inspired by kelp structures found along the coast of Malibu, California.

△Mini kelp pouchMade from bioplastic3DPrinted

The complex geometry of this bag is3DMade using printing, the designed voids help create a unique visual effect while making the bag lighter.Koernerexpress:”Mini kelp pouchEverything on it, like the buckles, hinges, and pockets, is made from plant-based polymers, using a single material.3DPrinted. At the same time, I analyzed naturally dried kelp and3Ddigitized, and based on the results of the analysis, this naturally unique3DDesign plan. “

△The design is inM.Q.Exhibited at Vienna Fashion Week

Used in Marvel films in the early years3Dprinting technology

Previously, she hadIris Van HerpenAndChaneldesign3DPrint haute couture.KoernerFirst contact at the University of Applied Arts Vienna3Dprinting technology, and has since combined its expertise with3DThe combination of printing technology has been applied toIris Van Herpenfrom high-end fashion to props and costumes for the Marvel movie “Black Panther”, and won the Academy Award for Best Costume and other awards.

△Black PantherUsing3DThe exquisite necklace and crown made by printing are obtained.2019Oscar for best costume

Exquisite costumes worn in the film include those worn by American actress Angela.· Bassett (Angela Bassett) plays Queen Ramonda (Queen Ramonda) wears a crown and a huge cape.

Koernerrecalls: “The directorRyan Cooglerhoping3DPrinting technology was introduced in the costumes of the Black Panther film. All I knew was that the film was about Africa and advanced technology. Everything was top secret. I didn’t even know the name of the film or the producers. “

Beige decoration with detailed filigree pattern, produced by selective laser sintering(SLS)technology makes it possible. This involves using a laser to heat a powder bed, melting the microscopic particles layer by layer, then removing excess material around them to reveal the finished product. These designs are linked to Belgiumcome to fruition(Maris) Co., Ltd.

△Mini kelp pouchAvailable in three colors including fuchsia

Inspired by the ocean, via3DPrinting becomes flexible

his design brandJK3DLocated between Vienna and Los Angeles,KoernerLive there now. She said: “This year9the month isJK3DDuring my first year in Vienna,M.Q.Fashion Week naturally highlights our unique product range andKelp Clutchlaunch. “

KelpThe mini clutch is available in midnight blue, slate and lilac, withJK3DofHYClutches andSlatThe side table collection was presented at the event along with the base. Both are used3DPrinting technology. With the help ofJK3D,Koernerdesigned to exploit3DPrinting technology is used to create designs that mimic nature, and more sustainable and environmentally friendly biomaterials such as corn or soy are highly recommended.

KoernerHe said: “With the help of3DIn printing, the brand is capable of producing customizable products with complex geometries. Our motivation is to create innovative, iconic and sustainable designs inspired by nature. “

She said:“We make it to order3DPrint, but can produce a pouch in one day, giving us the flexibility to personalize the pouch with initials or other personalizations. I believe the future of fashion is3DPrint. This technology allows us to rethink manufacturing processes, mass customization and personalization. “

△JK3Dalso showedHY ClutchAndSlatBase

She added:“3DPrinting is a sustainable way to keep up with constant changes in style, we can create designs digitally, present them virtually and work on only the designs needed.3DPrint. “

SOfuture fashion will definitely be inseparable from customization, and the most ideal way of customization at present is3DWith printing technology, you can add personalized decorations to your clothes at home. At the same time, clothing brand manufacturers can also sell customized products in batches or individually based on market feedback or customer needs. more in line with future market demand.

source:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.