Recently, according to Momon.com, Mohawk (Mohawk) innovative technology companies andVELO3DThe company collaborated on the development of a solid oxide fuel cell (SOFC), which is a promising new technology for energy preparation, with the help of Bike3D Reduce the price of anode exhaust gas recovery boosters 60%entered the commercialization phase from the research stage.

△Anode waste gas recovery blower

US Department of Energy (DOE) for many years have beenSOFCMake an investment (according to their website, since1995Invested over the years7.5billion) as part of ongoing efforts to decarbonize energy production. The Ministry of EnergySOFCDescribed as an electrochemical device that generates electricity directly from the oxidation of a hydrocarbon fuel (usually natural gas) while eliminating the actual combustion step. basically,SOFCLike an indefinite battery that constantly recharges—There is no need to burn the gas to charge it.

Small package, big power output

Mohawk Innovation Technologies Company (TREES) Vice President of EngineeringJose Luis CordovaThe doctor said:“Solid oxide fuel cells are very attractive because they produce large amounts of power in a very small package. Mohawk Corporation is a company with28The 20-year-old company, headquartered in Albany, New York, specializes in “clean technology“–Design oil-free turbomachinery products that are efficient, economical and have low environmental impact, including renewable energy turbogenerators and oil-free turbochargers./Blower and electric motor.Jose Luis Cordovaexplain:“SOFCThey are compact and can be built in factories and then transported to specific locations where they are needed to support distributed energy production. Compare that with typical multi-megawatt centralized power plants, which often take billions of dollars and years to build.SOFCIt is also very effective. Unlike regular batteries, they don’t lose power over time because you can continue the electrochemical reaction almost indefinitely as long as you supply the reactants.“

△MohawkInnovative technology companies andBike3Dbusiness cooperation,3DPrint fuel cell parts to reduce costs (dramatically).

Although in2019There are more than4Ten thousand units100kilowatt fuel cells (each capable of50houses) are shipped worldwide, but like manySOFCWidespread adoption of this technology has been limited by the fact that the components are expensive to manufacture and wear out quickly due to exposure to the gases that make them so effective.

Facing cost and sustainability issues

To help overcome these challenges,MohawkSome of these key components have been designed for extended life and increased efficiency. A typical example is the anode exhaust gas recovery fan (AORB)–“Equipment assessment“(supportSOFCan important part of the fuel cell machinery).

JoseHe said: “During operation, each fuel cell only uses approximately70%gas. The rest approx.30%Along with water (a product of the electrochemical reaction), it is discharged directly from the system. And you don’t want to waste that leftover gas or water, you want to send it back to the beginning of the process. It isAORBWhat it does: It’s basically a low-pressure compressor or fan that recycles exhaust gases and sends them back to the front of the fuel cell.“

Joseexplain:“a typical250kilowattSOFCThe factory will use two.SOFCThe factory balance designer assumed that this fan would be a commercially available unit. But traditional blowers are susceptible to corrosion and degradation due to process gases present in the system. The hydrogen in the mixture can attack the fan’s alloys and can also damage the magnets and electrical components of the motor that powers the fan. Most blowers also contain lubricants, such as oil, which can also degrade. As a result, you end up with a fan with very low reliability. – Represents a significant portion of the plant’s break-even costs – And yoursSOFCFactories require major overhauls every two to four thousand hours. “

This statistic falls well short of the U.S. Department of Energy’s goal ofSOFCThe lifespan is40000hours, installation costs vary from average12000Dollar/kilowatts (kilowatts of electrical energy) reduced to900Dollar/kilowatt.

Jose Luis Cordovaexplain:“We therefore realizeMohawkProprietary compliant, oil-free foil bearings (BFC), specialized coatings and decades of turbomachinery expertise are well suited to this challenge. “

Additive manufacturing provides the answer

Funding from the U.S. Department of Energy isMohawkprovided inFuel cellmanaged by energy companiesSOFCDesign and testing in a demonstration power plantAORBMeans of prototyping. Rigorous testing under realistic operating conditions measures durability and performance. The latest version has no noticeable degradation of components or output and completely eliminates any performance or reliability issues.

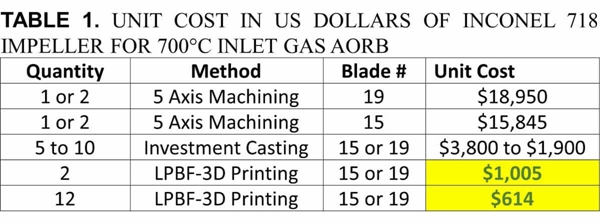

However,AORBThe cost remains prohibitive. This is largely due to its high-speed centrifugal impeller, which operates continuously under extreme mechanical and thermal stress. For maximum life, the part should be made from expensive, high-strength, nickel-based, corrosion-resistant superalloy materials such asInconel 718OrHaynes 282these materials are difficult to machine or cast. Achieving optimal aerodynamic efficiency in wheels requires complex three-dimensional geometries, which pose a manufacturing challenge. Additionally, due to the current situationSOFCIn the nascent state of the market, wheel production batches are relatively small and economies of scale are difficult to achieve.

Jose Luis Cordovaexplain:“As you can imagine, additive manufacturing offers an essential answer to reducing production costs. withFuel cell energyAs the initial plan for the collaboration continued to develop,MohawkResearch and development groups are also asking for help in designing their own fuel cell components. As many of these manufacturers and integrators are still in the research stage, each has different operating conditions in mind. Using traditional manufacturing methods, it would be very expensive to make only the small number of custom wheels or vortices desired. So we started to look at additive manufacturing. We ourselves researched manufacturers of additive manufacturing systems and worked withLPBFsupplierBike3Dconnect.

Collaboration on capabilities

Jose Luis Cordovaexplain:“Since its objective is to reduce costs and improveSOFCperformance, the Department of Energy is enthusiastic about innovative manufacturing methods such as additive manufacturing. Their funding (through the Small Business Industrial Research Program) supports our current work withBike3Das well as our previous collaborations withFuel cell energycooperation. Another advantage is that, like us3DThe capabilities and potential of printing technology are increasingly understood, and this work is helping to advance the entire industry.3DPrinting technology.“

Bike3DbusinessMohawkProject managerMatt Kareshexplain:“AndMohawkBy working with companies like this, their willingness to work with us and provide feedback advances our internal process metrics and capabilities and helps us improve our printing methods. “

The profitability of additive manufacturing

Jose Luis Cordovaexplain:“Each of our traditional subtractively manufactured turbines is up to15,000has19,000Dollar. when we use3Dprinting technology for8small batches of around 100,000, rather than one at a time, which brings it down to500arrive600dollars, which represents a very significant cost reduction. In addition to reducing manufacturing costs,LPBFis a technology that gives us the design flexibility we seek. Additive manufacturing is not limited by the number, angle or spacing of turbine blades, all of which directly impact aerodynamic efficiency. We now have the geometric precision required to enable more efficient rotary turbomachine designs while reducing associated manufacturing costs.“

Choosing the Perfect Alloy

existSapphire Velo3Don the system3DWhen printing a wheel (inBike3DContract manufacturers in a global networkDuncanMachine), choose to useInconel 718–One of the nickel-based alloys, it has strong temperature tolerance and can better withstand rotational stress.

MohawkCorporate mechanical engineerHannahLeaexplain:“InconelIt interests us because it is sufficiently chemically inert and retains its mechanical properties at fairly high temperatures, significantly more than aluminum or titanium.

althoughBike3DAlready certified for their machinesInconel718,butMohawkAdditional material research was carried out to add information about3DPrintable version of superalloy knowledge.Hannah Leaexplain:“Our tests show thatLPBF 3DprintedInconel 718Mechanical properties, such as yield strength and creep tolerance, are superior to those of cast materials. This is more than sufficient for high pressure blower and centrifugal compressor applications over the operating temperature range.“

Simplified iteration

As the work of the turbine progresses,Mohawkengineers andBike3DExperts collaborated on design iterations, revisions and printing strategies.Jose Luis CordovaHe said: “It’s really interesting because we haven’t had to make any major changes to the design of the original wheel that we were using.Bike3DWith the Sapphire system we can directly print whatever we want. We have made some modifications and adjustments to the process in terms of support structure considerations and surface treatment changes.“

As the turbine project progresses, additive manufacturing offers faster turnaround times than casting or milling because parts can be quickly printed, evaluated, iterated, and reprinted. in the sequel3DDuring a run, multiple examples of old and new turbine designs can be run simultaneously on the same build plate to compare results.

Due to the relatively small size of the wheel (diameter60mm), it was necessary for the team to develop a “sacrificial shield“–A temporary printed shell that preserves the authenticity of the blade during manufacturing.

Sacrificial shield and smoother surface

Bike3DofMatt Kareshexplain:“What’s really interesting about this approach is that shrouded wheels are essentially inaccessible to most current additive manufacturing technologies because they require all traditional support structures.“What we are adopting is not the absence of support, but a method of reducing support.MohawkHe says they don’t ultimately need the shroud, but the shroud makes the part better, so they usually attach this thing, which is usually extremely difficult to print, and then cut it. to useBike3dUsing this technology, they were able to build a unique fairing over the wheel, get the airfoil and channel shape they wanted, and then a very simple machining operation to remove the fairing.“

according toMohawkengineerRochelleBoisHe said surface treatment is another focus:“In our first iterations, the surface was a bit rough. The cool thing about the sacrificial shroud is that it gives us a flow path through the blade where we can use compression sharpening to correct the roughness. We had to do some more back and forth to determine how much material to add to the blades to achieve the desired blade thickness. The final surface finish we achieved was comparable to that of the casting, meeting our aerodynamic goals.“

Future tests, perspectives

The next step is to install a new wheelAORBand tested under field conditions.Jose Luis Cordovaexplain:“We hope that the successful execution of these two missions will provide ample evidence of theLPBFtechnology provided3DPrintInconelThe components provide a viable and reliable alternative for manufacturing turbomachinery components. Work is already underway to use additive manufacturing to create other blower components, such as housings and vortices.

Jose Luis Cordovaconcluded:”Through these DOE-funded projects, we were able to develop a library of common areas. Based on the original idea, we now have at least three completely different platforms that serve different energy capacities to support future clean energy advancements.“

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.