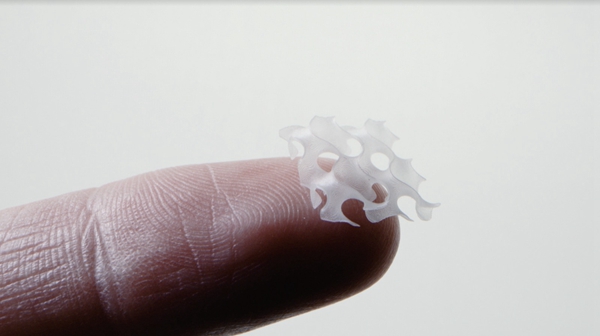

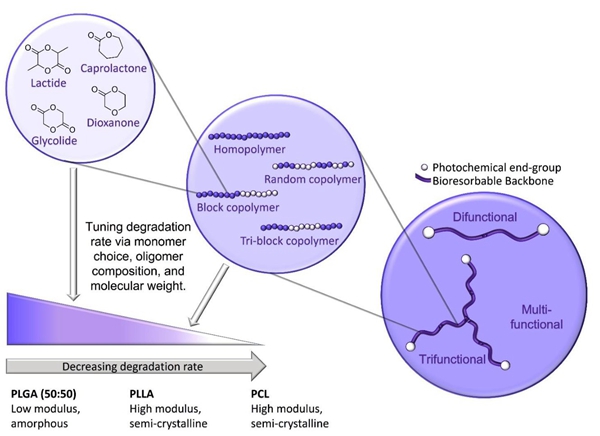

2022Year10moon29day,CarbonThe company uses photopolymerization3DThe printing technology developed a combination of biocompatible and bioabsorbable elastic materials that were biocompatible in vivo, and all samples were shown to be non-toxic and exhibit adjustable duration. This last step demonstrates thatCarbonBioelastomers have great potential for future applications in porous biomedical mesh structures, such as soft tissue repair, wound dressings, and nerve conduits.

In recent years, the Silicon Valley-based companyCarbonThe company leverages its high-speed photopolymerization of durable and responsive materials3DThe printer has made a name for itself.CarbonThe range of supported resin materials continues to expand and now includes more durable materials, up to40%materials of plant origin. However, it is the first biocompatible material used in implants. Bioabsorbable elastic materials under development have reportedly shown impressive mechanical properties, biocompatibility, and adaptability. This includes a degradation rate that can be adjusted to suit a variety of potential applications, making it versatile for a wide range of medical uses. Furthermore, current in vivo studies have demonstrated that implants26Required tissue tolerance and ideal healing response within weeks.

CarbonSenior Vice President, Corporate MaterialsJason Rollandexplain:“We are very happy to announce,CarbonThe developed bioresorbable elastomeric material platform demonstrated its in vivo biocompatibility. to useCarbonThese complex structures fabricated using digital photosynthesis technology could be the key to solving the long-standing challenge of optimizing the mechanical properties and degradation rates of implants. This is an important milestone and we look forward to working with interested partners to further develop applications for this resin.“

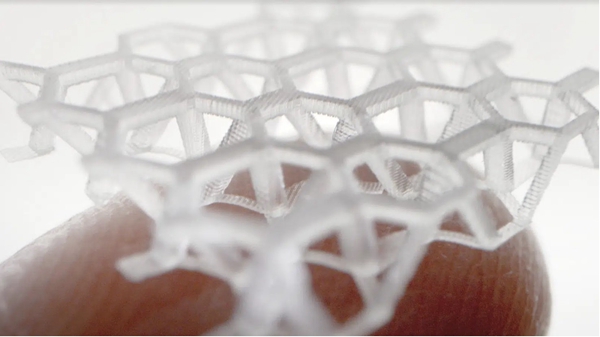

to useCarbon DLSAnd the printed grids of bioabsorbable elastic materials created by this resin hold great promise for the potential development of a variety of future biomedical solutions, for example in soft tissue repair. This implant could improve existing allografts and collagen-based allografts by reducing the inflammatory response, increasing elasticity and directionality, and improving the consistency of mechanical properties when repairing torn or thinned tendons.

Other uses for bioelastomers may include wound dressings, where absorbable mesh structures can promote healing while maintaining consistent force on uneven surfaces. They can also improve range of motion during healing while potentially reducing the need for repeated dressing changes and associated pain. Another use for the material could extend to nerve conduits, in cases of severe damage to the peripheral nervous system that would require surgery by a neurosurgeon.CarbonBioabsorbable elastic materials can improve existing solutions by increasing flexibility, porosity, neuroreceptivity and neuroconductivity.

△RUTFYesCarbonThe main component of bioabsorbable resin materials

Space filling applications in soft tissue surgery can also use these implants to fill the void left by the removal of a mass and allow natural tissue to grow to minimize deformity. Finally, the application of temporary mechanical supports could give rise to resorbable meshes. “carpet“Used in a variety of surgeries where tension or pressure on tissue must persist after surgery to minimize leaking or bleeding or to maintain soft tissue position during healing.

Source: Internet

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.