Scientists from the Ural Federal University and the Urals Branch of the Russian Academy of Sciences are jointly working on a project to identify hard magnetic compounds made of rare earth metals.3DOptimal conditions for printing permanent magnets.

This technology makes it possible to produce permanent magnets of any shape on a small scale, as well as to create complex permanent magnets and configure their magnetic forces. Such permanent magnets could be used to make micromotors and generators that could be used in devices such as pacemakers. Additionally, this technology minimizes production waste and allows for shorter production cycles.

Permanent magnets can maintain a magnetic field source for a long time and are widely used in various industries and equipment, such as the manufacturing of modern electric motors, household appliances and computer equipment. Permanent magnets made by traditional methods are difficult to make in small sizes and generally have two magnetic poles, one in the north and one in the south.

From a technical point of view, making small, complex permanent magnets is not an easy task. And3DPrinting technology can be used to create permanent magnets of complex shapes. After numerous experiments, Ural scientists managed to identify the use of selective laser sintering and magnetic powder3DOptimal settings for printing permanent magnets.

And3DPrinting can also change the internal properties of the magnet during the production phase. For example, changing the chemical composition of the compound, the degree of spatial orientation and crystallographic texture of the crystal, and affecting the coercive force (resistance to demagnetization).

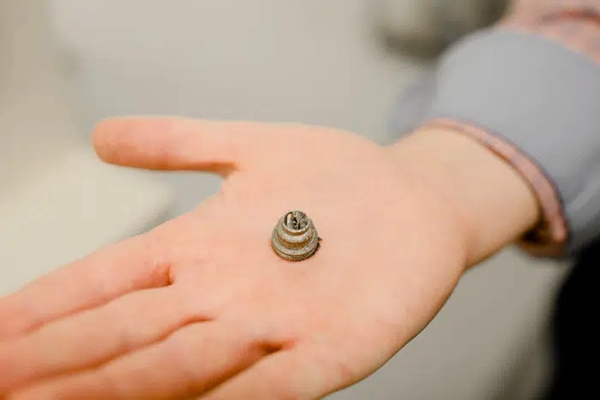

“It turns out that when small permanent magnets are manufactured, machining is generally used to grind large pieces of permanent magnets, and about half of the permanent magnets will become industrial waste.3DPrinting can avoid this and create complex permanent magnets, like the one with5Antarctic,5In the Arctic, such a configuration is necessary for a pacemaker. Currently, the rotors of the electrical motors of pacemakers are assembled microscopically using individual permanent magnets. “Researcher Dmitri–Neznakin (Dmitry Neznakhin) explain.

Currently they have3DPrinted only1The millimeter-thick permanent magnets are based on a powder containing samarium, zirconium, iron and titanium.

“We found that adding fuse powders of samarium, copper and cobalt alloys can preserve the magnetic characteristics of the main magnetic powder when the samples are sintered. Nieznagin added: “The melting temperature of this alloy is lower than the characteristics of the main alloy.” changes, which is why the final material retains its strength and density.

Source: Internet

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.