2022Year12moon8Japan, according to Mohou.com, FranceClaude RegaudClinicians from the institute and the Toulouse University Hospital carried out a nose transplant on a patient,3DUsing printing technology, she successfully realized her dream of reconstructing her nose.

△The forearm and3DBioprinted nose

2013A French woman who lost part of her nose to nasal cancer in 2011 had undergone several reconstructive surgeries without success. So she agreed to be a test subject for a new approach. This involves the patient taking a biological test3DThe printed nose was transplanted onto his forearm, where it grew for two months before being3DThe bioprinted nose was removed, revascularized and implanted on his face.

△Belgian bone graft developerCerum

First face transplant

The patient underwent radiation and chemotherapy for more than four years, resulting in the loss of part of her nose and the front of her palate.(the roof of his mouth). The patient was left without a nose due to a failed flap graft and difficulty wearing a facial prosthesis. As traditional treatments failed to achieve her goals, she had to undergo more experimental surgeries and witness3DThe whole process of bioprinting a nose that grows on one’s own skin.

To create a functional implant, surgeons teamed up with a Belgian medical device manufacturerCerumWorking with the clinical team, they contributed to the development of the biomaterial-based nose structure. It is then implanted and cultured in the patient’s arm, and once these preparations are complete, the blood vessel can be reconstructed using microsurgery.

In this procedure, a surgical connection is formed between two internal structures of the body, usually tubular structures such as blood vessels or intestinal loops. The Toulouse University Hospital had to connect the blood vessels in his forearm to those in his temple to ensure the implant would not be rejected.

According to the surgical team behind the procedure, it’s unique“Surgical intervention has never been performed on such a delicate and poorly vascularized area before.” Last month, the patient was hospitalized and given three weeks of antibiotics, but otherwise was “doing very well.”

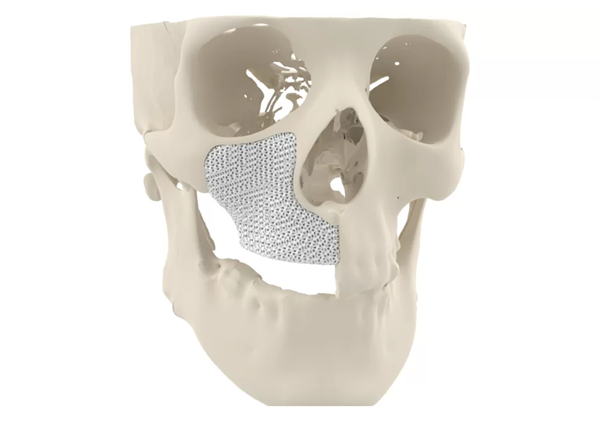

△CERHUM MyBone 3DPrinted facial bone graft

CerumofMy bonetechnology

as a bone graft3Dprinting expert,CerumIt can be said that his contribution to the operation played a key role. The company says its patented maxillofacial implantMy boneAlready approved for use in European patients earlier this year, the company says it has produced thousands for use in research and development, contract development and manufacturing organizations.(CDMO)and implanted devices.

These implants are based on fully biocompatible bioceramic technology and can be3DPorosity is controlled by printing and complex geometries can be customized to the patient. In fact, the3DThe printed implant is made from hydroxyapatite, a bone component known for its osteoconductive and osseointegrative properties, which promote colonization of the body’s blood vessels.

Compared to autografts and allografts,Cerumsaid the method is less invasive and less risky, while adding that its bioceramics are “better biocompatible than most synthetic materials.” The company also claims the material promotes faster healing than standard implants while reducing the time and number of surgical procedures patients must undergo.

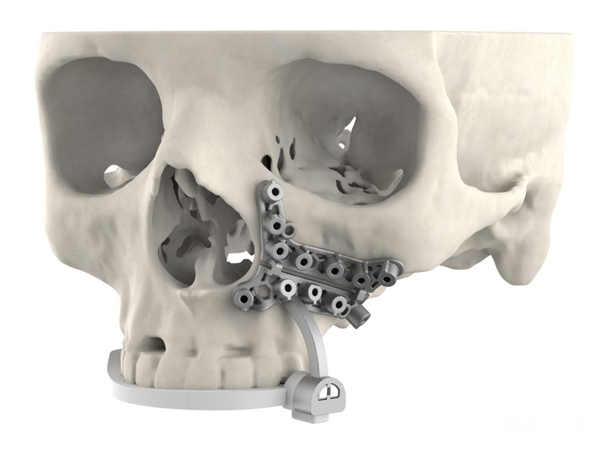

△ Attached to skull model3D systemsGuide to maxillofacial surgery

Cerumbone grafts are now on the medical market alongside several others3DPrinted maxillofacial guides and combined implants. last year,3D systemsA hybrid maxillofacial surgery guide based on titanium and nylon has been launched. It allows bite registration, allowing surgeons to operate on patients with more precision and confidence.

In the past, the Quebec Industrial Research Center has also usedGE Arcam Q10 Plus Additive 3D ModelPrinter develops patient-specific mandibular implants.

Source: unknown

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.