Recently, Mohou.com learned that Cloud Factory (YunFang), a full-service provider of designer jewelry design, production and fulfillment (including direct shipping) from EstoniaCloud Factory), it passes3DPrinting technology helps artists, designers, brands and gamers develop authentic jewelry.

△Cloud Factory personalized3DPrinted pendant

The company is made up of professionals from different fields. Users only need an idea, and the team will take care of the design,3DModeling, sending samples, packaging jewelry with custom brand logos, etc., and users don’t have to worry about minimum order quantities or inventory issues. Today, this model is changing the way traditional businesses operate.

The team said:“We are a team of very different people from different fields.Taavi Already in3DHaving worked in the printing field for over ten years, 3D FDMPrinter develops an operating system and teaches it to students and other startups3DPrinting experience. Co-founderMarekHolder of a doctorate in powder metallurgy, he worked in TallinnTalTecThe university serves as a scientist and solves the industry3DVarious problems with printers. “

The team:“I,AVERAGEthe only female founder, worked as a marketing manager in one of the largest and oldest nightclubs in the Baltics, dealing with different artist managers and promoters, having to be immediately aware of all the interests of young people in the club. I also have a degree in creative entrepreneurship in fashion design.ErikJoin us in the world of cryptocurrency, gold investing and affiliate marketing.TaaviRIGHT3DThe biggest interest is in printmaking and how it actually demonstrates the benefits of this technology. “

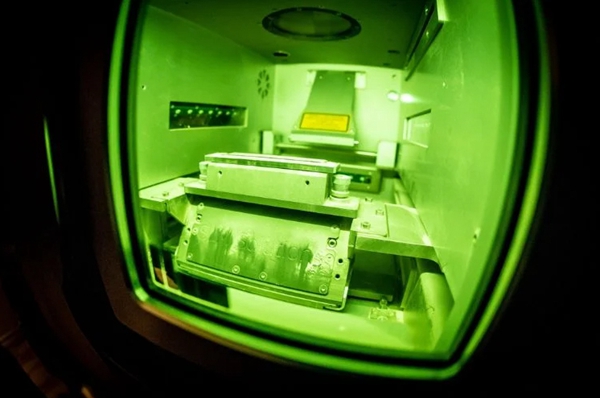

△Cloud FactoryofSLM125Metal powder bed fusion3DInside the printer (left) andBam Margeradesigned3Dprinted silver jewelry

3DHow did Print Cloud Factory get started?

AVERAGEHe said: “A chance,TaaviI had the chance to create metal jewelry for a global superstar. Then they andMarektogether they received government funding for innovation and contributed to the university’s industry3DThe printer was developed with fast and high quality settings. SO,TaaviLet me join the team to help you with branding, marketing and design. I immediately saw the potential for this company to be bigger than the superstar he met. From there, through my connections in the entertainment world, we were able to create samples for artists who were performing in nightclubs. We see the wonder in these artists’ eyes when we show them necklaces and rings with their logos and design elements. This business model immediately won their favor, so we decided to change the traditional operating model and become a “white label” manufacturing service provider for many artists, Internet celebrities and jewelry brands. “

Cloud Factoryuse metal3DPrinter to make silver jewelry

how to do it3DPrinted jewelry?

The team says that currently they only use925Solid silver. We have a partner who buys scrap silver from around the world and refines it into what we use directly as a metal.3DPrinted silver powder. We use selective laser melting technology, using100%Recycle money directly3DPrinted jewelry.

Many people ask us why we chose this printing technology. The answer is simple: it saves the most resources and avoids most of the tedious workflows compared to traditional manufacturing models. This allows us to automate all manufacturing processes and ultimately save time, materials and human resources. This technology best fits our ambitious vision to establish fully automated and sustainable jewelry printing centers around the world, offering brands a unique, fast and carbon-free service.

△Cloud Factoryfor fashion brandsUndesirableAndKiRiVOOand the playersCoryxKenshinprovide3Dprinted silver jewelry

Metal3DWhat are the advantages and limitations of printing?

The team said that among the technologies mentioned above,3DPrinting has many advantages. It allows us to offer ultra-fast and flexible production, customization, limited runs, new product launches and more in just a few days, and helps us reduce labor costs as much as possible artwork.

The only current limit is the creation of complexes3DModel product development time. For more detailed designs, the template creation process can take several days. That is why we are also working on developments that help us achieve fully automated workflows. For example, change2DDesign converted to3D. This will help us attract new customers faster than ever.

The team said:“We know the jewelry industry is lucrative, but it has been limited for centuries due to the need for deep production expertise, upfront payments and lengthy development processes. We are here to change the game, we want the jewelry industry to be adapted to this. inviting future generations to join an industry that is both traditional and modern, fun, affordable and good for our planet.

Ultimately, the team felt that the cloud factory was using3DThe printing process will certainly become a key part of the industry within ten years. Faced with increasing restrictions within the industry to end polluting practices, traditional manufacturers are looking for new ways to respect the environment and offer solutions that meet the needs of the next generation of customers.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.