2023Year1moon12March 1, according to Mohou.com, a company headquartered in Singapore3DPrinting service providerCreate3DDevelopment of an innovative and ultra-light satellite launch container – Zeus 1 (ZEUS-1), this container will beEspaceXThe rocket is sent into a predetermined space orbit.

Create3DdevelopedZEUS-1Satellite Container is a partner ofQosmosysAndNuSpaceJointly developed, this container’s unique structural design is designed to load50A gold anodized work of art. These works of art were laterEspaceXLaunched into orbit to celebrate pioneers10The detector is launched50birthday. to use3DPrinting technology, these companies discovered they could reduce the mass of satellite media50%Importantly, it also significantly reduces costs and delivery times.

NuSpaceCEO and co-founder of the companyNg Zhen Ningexplain:“The initially proposed design was made from sheet material. It can cost up to4000has5000dollars and a long delay of at least three weeks to get the machine-made parts to us, while3DIt only takes two to three days to print the part.“

△The rendering in orbit of the Zeus-1 satellite. Photo ofQosmosys。

Create3D: More than just a reseller

At first glance,Create3D seems to be different from other Singaporeans 3D Printer resellers and service providers (e.g.GOLDEN 3DOr3D printing Singapore ) are the same, but offer similar products, such as: traditional polymers, metals and ceramics3Dprinter, and3Dprinting software packages and post-processing systems, but it also offers customization for demanding use cases.

Since2012Since its creation,Create3DAlready with150Cooperation with several business partners and research institutes. This places the company at the industrial level3Dgained a lot of experience in printing projects and last year used this knowledge to helpQosmosysCompany develops device capable of operating in the cold vacuum of spaceNASAPersonalized products.

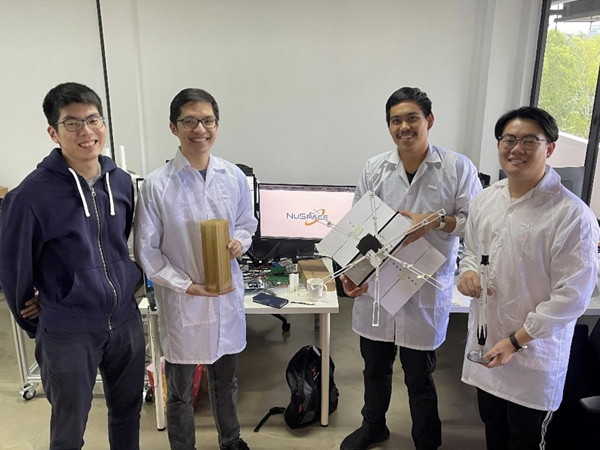

△InNuSpaceinstalled in the office3DPrint the test container. photo ofCreate3D

A tribute to aerospace innovation

Good speed On-demand orbital launch project Qosmosys Launched to celebrate the pioneers 10 The launch of the issue is 1972 Year NASA The probe that accomplished the first mission to Jupiter. However, even ifQosmosysThe decision had been made to fill the satellite’s test containers with artwork commemorating Pioneer’s launch, but they initially had no idea how best to accomplish this.

Traditionally, CNC machining or sheet metal forming would be used to create an aluminum enclosure, but since repeating such a part would involve bending and sawing,QosmosysThe company believes this is invalid. Another question to consider is “exhaust“a problem in which operating pressure in the space causes gears to release gases that can become trapped and damage nearby components.

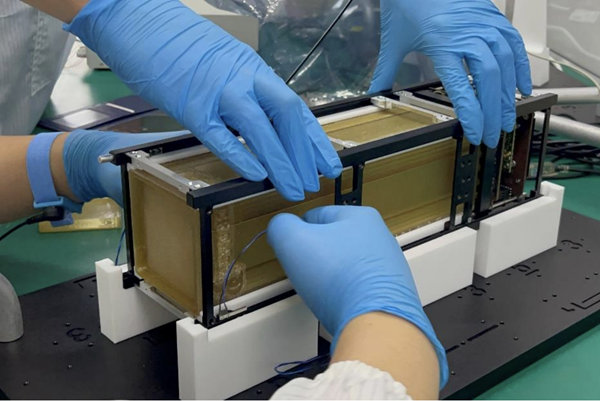

In order to solve these problems,QosmosysAndCreate3DAndNuSpacecooperate, useAntero 800NAdeveloped a shell which is aStratasysMaterial with high chemical resistance and low outgassing. After printing, the test container should be small enough to fit insideZeus-1inside the satellite holder. To ensure this,Create3DI said he adjustedNuSpaceprovided by the companyGUJATThe wall thickness of the model, thus creating a “like hands and gloves “parts.

pass3DThe weight of the printed test container is362grams, it is said that it is better than the traditional6061Made of aluminum800Grams are much lighter. Overall, NASA says the cost per launched payload is1million, the team says its approach could help make Zeus 1 more profitable in other ways as well.

Zeus 1 in2022Year12moon18Take a tour from Cape Canaveral, FloridaEspaceXThe company’s rocket has completed its launch.

△NuSpaceteam and final3DPrint the satellite hull. photo ofCreate3D

satellite3DContinuing advances in printing

Today, aerospace3DPrinting has reached such an advanced stage that the technology is deployed not only in the production of satellite accessories, but also in the creation of the spacecraft itself.2022Year7moon, 3D systemsThe company announced that it hadFleet spaceCompany signed3DContract for the printing of radio frequency patch antennas for use on its Alpha satellites.

Last year, Boeing also unveiled a new high-throughput small satellite3DPrinting facilities. This resort is located at2022The technology, expected to enter service by the end of the year, would be deployed to speed up satellite production and create a complete space bus.

Although it is not strictly speaking a satellite,Alba Orbitalof3DPrintPocketQubeLaunch vehicles are often used to propel such devices into orbit.Alba Orbitallow costAlbaPodThe deployer consists entirely ofCRP technologyofWind Shape XT 2.0manufacturing of composites in2022It was used to launch several microsatellites during the year.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.