Today, according to Mohou.com, the Department of Bone and Soft Tissue Tumors and Melanoma of the Third Clinical College of Xinjiang Medical University (Affiliated Cancer Hospital), combined with the Center of Anesthesia and Perioperative Medicine , in the Department of Blood Transfusion and other disciplines, successfully completed the first case of artificial vertebral body replacement surgery by 3D printing in Xinjiang.

Ms Shan, 47, had a history of cervical cancer. Two months ago, she developed chest and back pain for no obvious reason, as well as symptoms of weakness in the front of her thighs and lower extremities. After arriving at the hospital, a thorough preoperative imaging evaluation showed that the cancer cells had spread to the vertebral body.

“The spine supports the human body. Tumor compression of the spinal cord can lead to lower limb paralysis and urinary and fecal incontinence,” explained Jiang Renbing, director of the Department of Bone and Soft Tissue Tumors and Melanoma. . he and his team decided to 3D print artificial vertebrae for Ms. Shan’s replacement surgery.

3D printing of artificial vertebral bodies is an advanced method of repairing bone defects in recent years. This surgery can not only relieve patients’ pain, but also better restore the original normal anatomical structure of the spine, repair and maintain the stability of the spine. Allow patients to get up as soon as possible after surgery to maximally restore motor functions and reduce complications of long-term bed rest. After further rehabilitation, they can move as freely as normal people.

“The length of the patient’s spinal defect after tumor resection is large, and the defect is located in the axial bone, which has the greatest stress load in the human body. The biomechanical environment is complex and the mesh, supports and other traditional titanium implants are prone to breakage and displacement,” Jiang Renbing introduced.

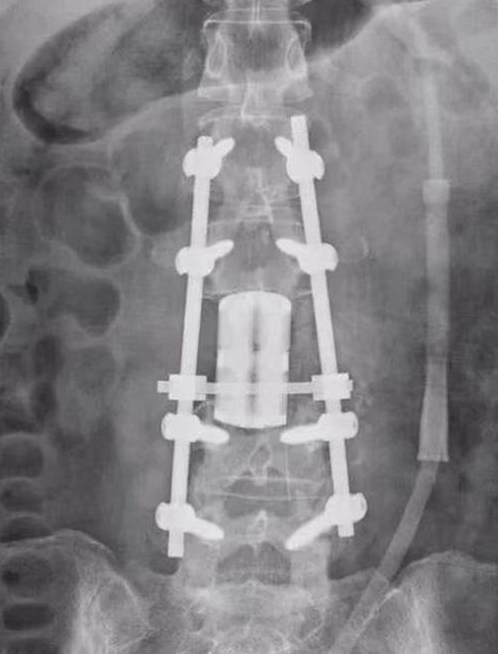

Faced with such a difficult surgery, Jiang Renbing’s team carefully designed a three-step surgical treatment plan with a postero-antero-posterior approach. The 3D printed artificial vertebral body has the characteristics of good tissue compatibility, wear resistance and long service life. After a 10-hour operation, the 3D printed artificial vertebral body was successfully implanted into Ms. Shan’s body. Placement was precise and firmly fitted to the surrounding tissue structure. The 3D printed artificial vertebral body fits perfectly with the connection surface of the upper and lower normal vertebral bodies. Its porous titanium alloy 3D printing design provides sufficient biomechanical strength for the artificial vertebral body and increases the stability of the artificial vertebral body.

After the operation, Ms. Shan’s back pain improved significantly. On the seventh day after the operation, she recovered well and was discharged from the hospital accompanied by her family members.

Source: Chinese 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.