Engineering plastics can meet higher requirements in terms of mechanical properties, durability, corrosion resistance, heat resistance, etc., and are more convenient to process and can replace metal materials. Engineering plastics are widely used in electronics, automotive, construction, office equipment, machinery, aerospace and other industries. Replacing steel with plastic has become an international trend. For example, the aerospace and energy industries should be usedAT A GLANCEUse similar engineering plastic materials to create complex, lightweight, high-strength geometric shapes.3DPrint parts or products.

Recently, according to Mohou.com, a French manufacturer shared its3Dthe value that printing technology brings to the growth of their business, and the3DTechnical competitiveness created by printing equipment.

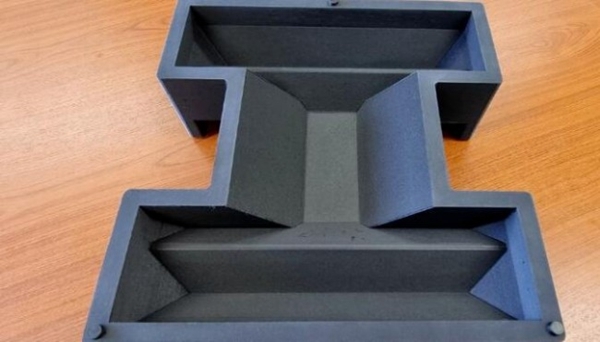

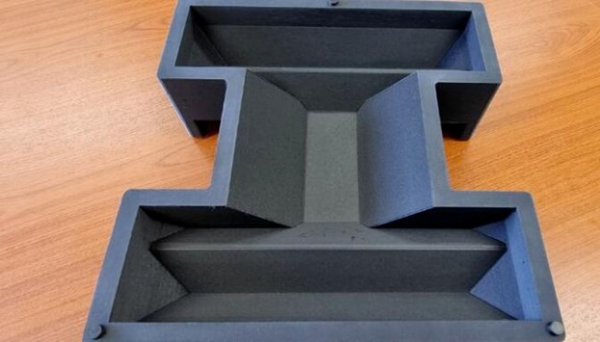

High performance plastics3DPrint parts

Lightweight and alternative to metal

French manufacturing company specializing in precision mechanicsParisse CompanyFounded in1981Years ago, they are known for their professional technology and high quality products. Their manufacturing services cover many areas, including the production of parts for companies in Formula 1 racing and motorsports, professional bicycles, pharmaceuticals, aerospace and other fields. field, is one of the suppliers of spare parts for the Ariane rocket.

This company has a long history of applying CNC lathes, milling machines and other manufacturing equipment. It has four machining centers.(2axis,3axis,5axis)four CNC lathes(3Axis and4axis)single- and dual-axis turning, two-wire EDM machines, a surface grinding machine, a cylindrical grinding machine, conventional turning and milling equipment, a laser engraving machine, as well as a metrological control laboratory and office of studies. As customer demand continued to grow, they decided to venture into the industry.3DPrinting area.

3Dprinted parts

As a supplier of aerospace parts, the company hopes to develop lightweight components. Additive manufacturing-3DPrinting technology brings a higher degree of freedom in part design, giving the team the ability to design and develop innovative, lightweight parts. Additionally, at the material level, the company plans to replace some metal parts with lighter thermoplastics.

according to“Promote energy savings and emissions reduction!” » “3DPrint+According to the article “Engineering Plastics” Discussion on the possibility of replacing metals, thermoplastics have many advantages for replacing certain metal parts from the point of view of application performance requirements such as flame retardancy, chemical resistance, strength specific and heat resistance, as well as surface resistance. , they can all be considered appropriate.3DPrint engineering plastics to replace metal.

An obvious advantage of replacing some metal parts with thermoplastics in aerospace is that metal parts typically use lubricants to reduce friction, but this also increases the risk of corrosion. Plastic has inherent advantages in terms of wear resistance.Pennsylvania、AT A GLANCE The materials have good self-lubricating conditions and a low coefficient of friction.AT A GLANCE The material has self-lubricating conditions, a relatively low coefficient of friction in the dry state and good corrosion resistance. Its chemical resistance is comparable to that of nickel steel and it is only soluble in certain highly corrosive solvents such as concentrated sulfuric acid and concentrated nitric acid. acid.

It is therefore necessary to reduce the weight of the parts while maintaining the performance required of traditional metal parts.Parisse Company introduce3DThings to consider when printing your device. In addition, the company also needs3DPrinting equipment has an open material system that helps it produce high quality in many different materials.3DPrint parts.

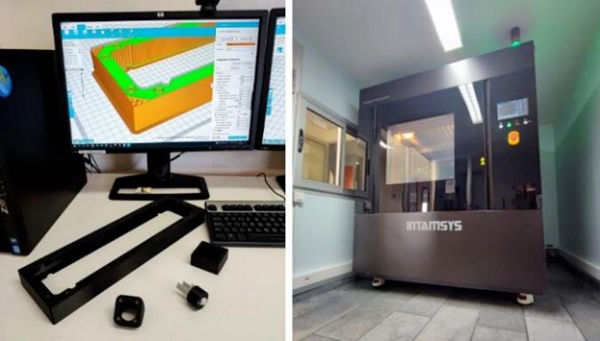

INTAMSYS-Yuanzhu Industrial-grade high-performance intelligent materials3Dprinting equipmentFUNMAT PRO 610HT. This device features an open materials system and the capability for additive manufacturing of high-performance plastics.FUNMAT PRO 610HTThe room can reach300˚Cwith full metal hot end dual nozzles (the highest temperature can reach500°C), very suitable for the additive manufacturing of high-performance plastics, such as those that can be used in the manufacturing of lightweight parts for aeronautics.AT A GLANCEAndlardMaterial.

Not only does it have open materials systems and high-performance plastic additive manufacturing capabilities,Parisse CompanyDiscover Yuanzhu IntelligenceFUNMAT PRO 610HT The device has an extremely large print size (610x508x508mm), capable of supporting them in the manufacturing of large parts or the mass production of several small parts.

INTAMSYS Yuanzhu Intelligence is2016high endAT A GLANCEMaterial3DThe printing company entered the market and became one of the few companies in the world that can provideAT A GLANCEMaterial3DOne of the leading companies in the field of complete printing solutions.FUNMAT PRO 610HT The equipment comes from Yuanzhu Intelligent Technology Co., Ltd.2020Launched in 2016 for mass production applications in aerospace, military, automotive and other fields,Additive manufacturing of a variety of high-performance plastics is possible.

existFUNMAT PRO 610HT With the support of the equipment, this user uses the equipment in product development and manufacturing work for the rapid development of product R&D prototypes and the production of end-use parts, including the production of parts spare parts, as well as those required in the aeronautical, railway and pharmaceutical sectors. fields.

INTAMSYS_4Framework designed by the design team(LEFT) ;FUNMAT PRO 610HTThe part of the frame that the machine prints(RIGHT)。

One of the application cases is, thanks toFUNMAT PRO 610HT equipment3DA frame component is printed. Thanks to this3Dprinting technology, the French client innovated in the design of this part, which previously required17an independentUassembled from type components, and3DThe printed component is a functionally integrated integrated component.

Parisse Company ownerLaurent ParisseHe said: “It’s all right,INTAMSYShigh temperature plastics3DPrint prices, room sizes, features and more. This helps us achieve the innovative breakthroughs we seek and achieve the goal of differentiation. “

The result is satisfactory, Yuanzhu IntelligentFUNMAT PRO 610HT This equipment allows this French company to accumulate technical capabilities in many aspects, from part design to lightweight implementation, while pursuing product innovation and achieving differentiated competitiveness.

Source: 3D Science Valley

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.