On March 2, 2023, Mohou.com learned that Materialize, a 3D printing and digital manufacturing solutions service provider headquartered in Belgium, announced its cooperation with Exactech.

3D printed implants for Materialize

Exactech is a US-based company that develops and produces innovative implants, devices and smart technologies for joint replacement surgery. By now working with Materialize, they will be able to add Materialize’s Glenius 3D printing technology solutions to their product portfolio to provide personalized implants to patients with severe shoulder defects, enabling surgeons in Europe and beyond. Australia to offer a more comprehensive shoulder product portfolio.

Chris Roche, Senior Vice President of Exactech’s Limb Division, said: “With the addition of the Materialize Glenius implant to our existing product portfolio, we are providing surgeons in Europe and Australia with greater choice. wide range of products for the shoulder. We are excited to work with Materialize. ,Bring more personalization technology and artificial intelligence to shoulder reconstruction.

△Materializing the Glenius implant can help older people improve their quality of life

3D printed implants completely replace traditional treatment options

It is reported that shoulder arthroplasty accounts for approximately 60% of orthopedic limb surgeries and is one of the fastest growing areas of the orthopedic surgery market. As expectations for patient satisfaction continue to rise, surgeons are seeking new treatment options to achieve better clinical outcomes in difficult cases. Orthopedic surgeons can now use Materialize’s custom implants to treat patients with significant scapular bone loss who do not achieve good results with standard and enhanced inverted shoulder implants.

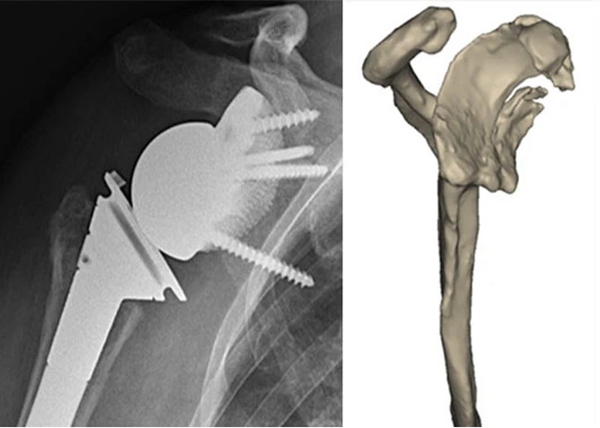

△In this case, the doctor found that the patient suffered from a serious degenerative disease of the shoulder joint and the top of the glenoid was completely missing, so he decided not to use the base plate traditional reverse for total fixation of the shoulder joint in this case.

Materialize said a patient named Mr. Terwiel needed a shoulder replacement. Due to the severity of this patient’s condition, traditional prosthetics may not be able to provide adequate support and stability. So doctors opted to use the company’s custom implant, Glenius, to create a custom-made shoulder prosthesis for her.

The company’s clinical engineers used the patient’s CT scan data and 3D technology to design a custom shoulder prosthesis for her, and provided doctors with a 3D-printed surgical guide to help them better install the prosthesis . After the successful operation, Mr. Terwiel recovered well and is now able to perform various activities on the shoulder. This case demonstrates the effectiveness of Materialize’s personalized implant technology and proves that it can provide better patient outcomes.

△Materialize Mimics Planner can improve the therapeutic effect of thoracic surgery

Growing demand for personalized medical devices in plastic surgery

Materialize Glenius is a professional medical 3D printing solution from Materialize designed to help doctors and patients deal with shoulder joint diseases and injuries. Using this technology, the two companies will in the future be able to produce customized shoulder joint implants and guides based on patients’ individual needs and anatomy, helping doctors perform surgical procedures with more precision and improve the success rate of surgical interventions and the quality of patient recovery.

Materialize said its clinical engineers use 3D data, simulation and artificial intelligence technologies to design each Glenius implant based on the patient’s unique anatomy. By optimizing implant fixation and stability while maximizing bone preservation, it is designed to achieve more predictable clinical results in the most challenging humeral cavity erosion situations.

Brigitte de Vet, Vice President of Medical at Materialize, said: “The plastic surgery industry is experiencing increasing demand for personalization of medical devices. Medical device companies should start with high-value use cases and then gradually expand to higher-volume applications to achieve big results. at scale Materialize is committed to helping researchers, engineers and clinicians innovate personalized treatments to improve clinical outcomes.

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.