In this issue, Mohou.com will share with you a case of cooperation between EOS and ice hockey equipment brand Bauer Hockey in the field of 3D printing of personalized helmets. You will then be able to experience the benefits that 3D printing technology brings to the design. and manufacturing of ice hockey helmets.

EOS and Bauer Hockey Team Up to Create New Custom Ice Hockey Helmet

What a good headset should look like

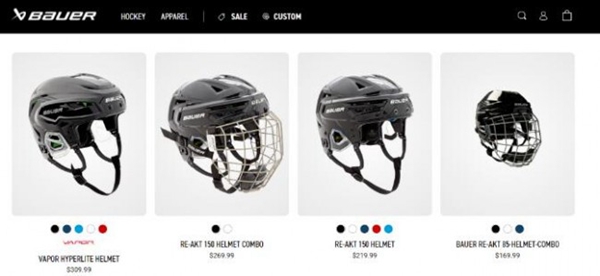

Hockey helmets have been in development for more than 50 years, and new 3D printing technologies are changing product development and the consumer experience in unprecedented ways. Bauer Hockey, a global leader in ice hockey equipment innovation, has partnered with EOS to integrate additive manufacturing into its MyBauer custom equipment program.

The MyBauer REAKT ice hockey helmet uses Digital Foam technology developed by EOS based on 3D printing technology to ensure a perfect fit for each person’s unique head. Bauer Hockey hopes this partnership will enable the commercial production of custom helmets.

Mathieu Dejardins, Senior Brand Manager for Protective Equipment at Bauer Hockey, said: “Bauer Hockey is pursuing ‘mass customization’ and through collaboration with EOS and other partners, Bauer Hockey is expanding the MyBauer custom hockey equipment, including production of custom helmet liners. on a large scale Although Digital Foam technology is still relatively new, it allows Bauer. Hockey leads the way in product innovation and pushes against other engineering and manufacturing constraints.

The helmet, developed with digital foam technology, is currently on general sale as a specific item in the MyBauer product line.

What is Digital Foam™?

Digital foam based on 3D printing technology is made of very flexible plastic materials such as TPU or PEBA. Each voxel (volume pixel) can be precisely adjusted to create more comfortable, safer, lighter and more secure products.

Through a comparative survey of all manufacturers of industrial 3D printing equipment, Bauer determined that EOS and its patented Digital Foam technology for plastic additive manufacturing – 3D printing gave them a clear advantage and included them in the cooperation plan.

With the launch of the third generation of REAKT helmets, the days of simple small, medium and large sized products are over. By scanning the player’s head, creating a digital file, then using EOS’ Selective Laser Sintering (SLS) technology, the helmet liner is 3D printed with digital foam to fit the head perfectly of the wearer. This technology not only incorporates a complex and changeable mesh structure. provides the wearer with personalized services, but also improves comfort and provides greater breathability and weighs only 580 grams. Once the 3D printing is completed, the helmet liner will be painted and other post-processing processes will be carried out for final assembly.

Bauer REAKT helmet liner 3D printed using EOS digital foam technology

EOS obtained a patent for Digital Foam™ technology and carefully launched the Digital Foam™ program with the Additive Minds application engineering team starting in 2019, with the aim of simplifying the steps required to implement into the market for 3D printed digital foam products to speed up the process. the development and production of digital foam applications for 3D printing.

Currently, across many industries, from automotive to footwear, athletics to protection to medical, there are common themes and requirements that call on Digital Foam as a solution.

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.