Recently, according to Mohou.com, Canadian startup Fortis3D is launching two new polymer 3D printing materials for industrial applications, namely PA-GF20 and PK-GF20. When launching new materials, Fortis3D also carried out a detailed analysis of the material properties of each filament to enable engineers to find suitable application scenarios based on the material’s advantages. Drawing on experience in polymer engineering, Fortis3D’s team of scientists and engineers created reinforced polyamide (PA or nylon) and polyketone (PK) 3D printing filaments that are stronger than conventional other filaments and fiberglass.

Wayne Lam, commercial director at Fortis3D, said: “We have found that most fiber-reinforced filaments on the market can produce relatively strong and rigid parts, but they are nowhere near as strong as fiber-reinforced resins. used for traditional injection molding. we also wanted to do more. With these two goals in mind, we developed these two materials to be the strongest on the market and even allow use in high strength materials. Users of high-end printers produce parts with very high strength.

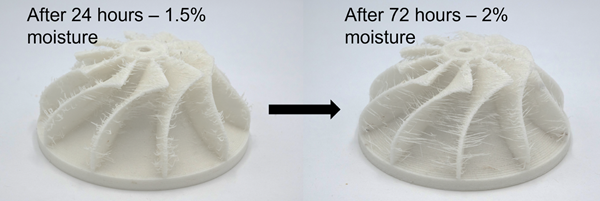

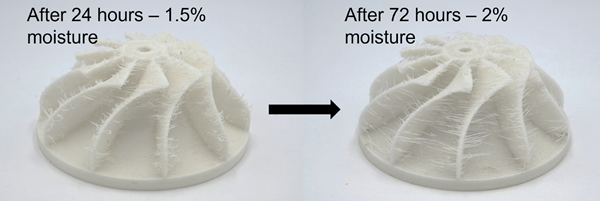

△PA6GF hygroscopic diagram. Photo by Fortis3D

Features of PA-GF20 and PK-GF20

Fortis3D’s PA-GF20 and PK-GF20 crushed fiberglass reinforcement materials are used for 3D printing high-performance functional parts. In addition to their excellent mechanical strength, both materials are resistant to chemicals, temperatures, impact and abrasion, making them durable in harsh environments. Applications of these materials range from covering industrial final parts to lighting fixtures. Most other fiberglass-reinforced filaments in the industry use very short (100-300 µm) ground glass fibers and incorporate them into various resins. Although they have good strength and printability, they can be brittle. Cut fiberglass is longer (3mm) and offers very high strength while retaining more of the toughness of the base plastic material, but it is more difficult to assemble. Both types of fiber typically break down more during the blending process, resulting in shorter fibers in the final product. Care should therefore be taken during processing to minimize fiber breakage.

△3D printed parts using the PK-GF20. Photo by Fortis3D

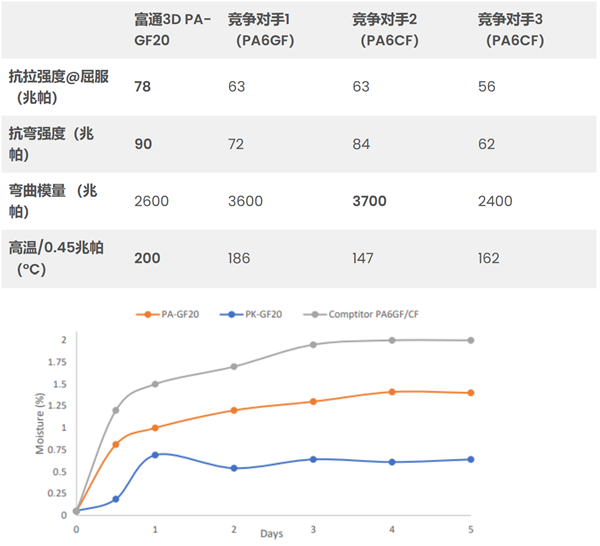

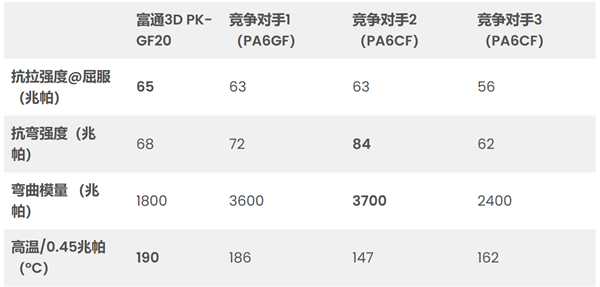

Technical data on PA-GF20 and PK-GF20 3D printing materials

The Fortis3D R&D team has optimized fiber loading and processing variables to produce one of the “strongest” fiber-reinforced PA filaments in the industry, with low fiberglass loading. Reduced fiberglass filler improves printing performance, nozzle wear and surface finish. In order to achieve a high tensile strength of 78 MPa after adjustment, the R&D team also used a chemical coupling agent to strengthen the adhesion between the glass fiber and the polymer matrix. Compared to injection molding, the tensile strength retention exceeds 90%, making it stronger than other major brands of glass fiber and carbon fiber reinforced nylon materials. When using a nylon copolymer similar to Fortis3D’s SnapPrint PA, moisture absorption is reduced by 30% compared to typical PA6GF filament. Compared to PA6GF filament, cross-stringing is minimized even when the filament is placed in ambient conditions.

△Schematic diagram of moisture retention calculated in days. Photo by Fortis3D

Polyketone (PK) is a terpolymer of propylene, ethylene and carbon monoxide. Its characteristics are similar to PA12, but it has lower hygroscopicity, higher chemical resistance and impact resistance, and correspondingly reduced friction and wear. It also retains its mechanical strength after absorbing moisture, unlike nylon. In terms of environmental protection, polyketone production produces 60% less carbon dioxide than nylon production. However, printing alone is very difficult due to excessive warping of PK printing and lack of adhesion to most adhesives and bed materials. To solve this problem, the Fortis3D development team created a proprietary formula that significantly reduces warping and fits most bed materials using only PVA glue. Chopped glass fibers are added for added strength and rigidity, allowing this material to compete with other carbon fiber or glass fiber reinforced nylons in the industry without the risk of excessive moisture absorption. Hygroscopicity is reduced by approximately 70% compared to typical PA6GF filament, meaning that over a week of environmental conditions, tandem connections are limited and part strength is not affected.

Filament series products currently sold by Fortis3D include SnapPrint PA, Lignum PLA, BioDuro Metallic PLA, etc. Fortis3D claims that its filament is made from high-quality materials and that each spool undergoes strict quality control standards before shipping. According to Fortis3D, the company’s production facilities are GMP certified and ISO 9001:2015 registered, ensuring “state-of-the-art” consistency in diameter, ovality and color from batch to batch. .

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.