On March 27, 2023, according to Mohou.com, New Zealand’s Royal Research Center Scion developed an innovative and bendable 4D printing material. This material is a mixture of wood fibers and PLA (polylactic acid), which can be 4D printed at room temperature to form a self-assembled structure.

△The Scion Research Center commercializes the Morph materials they developed (from left): Beatrix Theobald, Robert Abbel, Angelique Greene, Ben Davy and Rob Whitton

The self-assembled nature of the material gives it a variety of potential applications, such as medical, electronics, construction and others. It can be used to make reusable medical equipment, smart electronic devices, building materials, etc. Additionally, the development of the materials will help promote local economic and educational development in New Zealand.

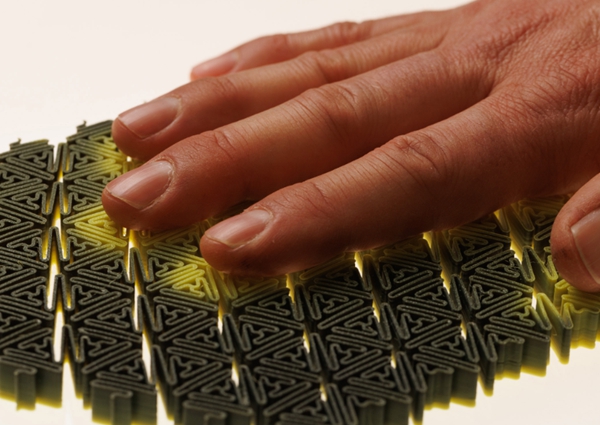

△Morph is a flexible filament material that is also thermochromic. For example, when you hold it in your hand, its color changes from black to yellow.

Morphing 4D printing materials

Today, a new material “Morph” successfully developed by Auckland 3D printing materials manufacturer Imagin Plastics and research institute Scion has been launched.

The material is “called 4D printing material” because it adds a fourth dimension, “time,” to 3D printing. When the material is exposed to a heat source, it can react with changes in color and shape. , it is called 4D printing material.

The bendable material could be used to create a variety of fun items, including bath toys that change color with heat. It is the only collapsible material of its type in New Zealand. 3D printing enthusiasts can now use this new material to print objects that are more resistant and have better plasticity.

△4D printing materials change color when heated and can be used to create interesting and flexible objects that children will love.

4D printing materials make more and more children like them

Dr. Angelique Greene, development scientist on Scion’s Morph team, said the product could be used to teach students the concepts of 3D printing and add a scientific component with its flexibility and thermochromic properties. She said: “There are other interesting 4D printing materials on the market, but they are generally rigid. We wanted to create a unique, stretchy material and increase its functionality. Morph is a material that is both soft and warm. The sensitive printing filament material changes from black to yellow when it detects temperature changes, such as when you hold it in your hand. “This is the first product to combine these two properties.”

Angelique said Scion will also use it for community education. She explained: “As a royal institution, our role is to support the industry, but also to support the communities in which we operate. We can do that with Morph.” Morph is made from a soft, biodegradable polyester. During development, Scion scientists successfully printed numerous objects, including phone cases, animals such as geckos and octopuses, and moving objects such as stretchy bracelets.

During the upcoming school holidays, the Scion Research Center will host an interactive 4D printing workshop at Rotorua Library to introduce young people aged 11 and over to new materials and 3D printing technology. This initiative aims to promote this color-changing and bendable 4D printing material so that more people can understand and master 3D printing technology.

Ben Davy, sales and technical director of Imagin Plastics, said they have had a cooperative relationship with Scion for many years on different projects. The development potential of this project has two aspects for them: one is to further develop the relationship and the other. The other reason is that 4D printing materials are introduced into the market. “We want to provide printed material for use in education, such as high schools and universities, that has a fourth dimension. This opens up new research and development opportunities for students,” he said. he declared.

Ben said that in addition to education, Morph also has the potential to be used in areas such as the automation industry. “For example, mechanical components in the packaging and food processing industries could use it to detect temperature changes, or even artificial intelligence could be programmed to recognize them.”

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.