2023Year5moon6The same day, Mohou.com learned that Italian metal3DPrinting service providerBEAMITand Germany’s leading aircraft engine manufacturerMTU aero enginesCooperation will jointly develop metal3DPrinting jet engines. This collaboration will focus on the useTi64and other alloy materials, and is designed to provide more efficient and reliable components for future aircraft.

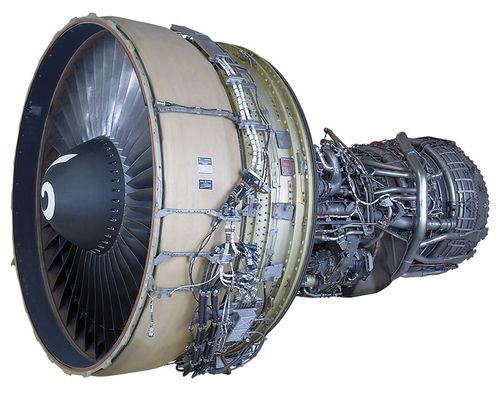

△PERSONForCF6Manufacturing of parts for turbines and compressors

Aero engine manufacturers seek better-designed solutions

BEAMITExtensive experience in the aerospace, defense and aerospace sectors, including the acquisition of leading polymers and metals3DPrint Manufacturing Supplier3T additive manufacturingsuccessively withGEAndLeonardCooperation to achieve national defense3DPrint Industrialization, in collaboration with its parent companySandvikCooperate to develop superalloys.

futurePERSONwill be responsible for engineering and design,BEAMITthen provide3DPrinting expertise. Both companies share the goal of providing the aerospace industry with lighter, more durable and more efficient high-performance engine components.

BEAMITPresident and CEOMauro Antolotti“We are delighted to partner with the global leader in aerospaceMTU aero enginesCollaborate to push the boundaries of what is possible with additive manufacturing. Our team will work closely to design and manufacture titanium components that meet the high standards of quality and performance required for aerospace applications.

△In2021Year,BEAMITGotNadcapWelding Certification

PERSONSenior Director of Additive Manufacturing Technology at Aero EnginesKarl Heinz“We are always looking for ways to push the boundaries of what is possible with new manufacturing technologies,” said Dr.BEAMITThe collaboration will allow us to explore the use of3DPrinting technology is a new way to create high-performance components that help improve the efficiency and performance of our aircraft engines. “

BEAMITThe company is one of the few super services organizations with the capital, certifications and expertise to work with the most demanding defense and aerospace customers. The company worked withMorf 3D、come to fruition、Sintavienne、MIMO technologyCooperate with companies such as Airbus, Boeing, Lockheed, General Electric, Pratt, etc.3DPrinting contractor.BEAMITWill play an important role in the emerging fields of space, satellite, defense, drones, aerospace engines and aerospace, becoming one of the leading contractors working with Airbus, Boeing, Lockheed, General Electric, Pratt and other companies.

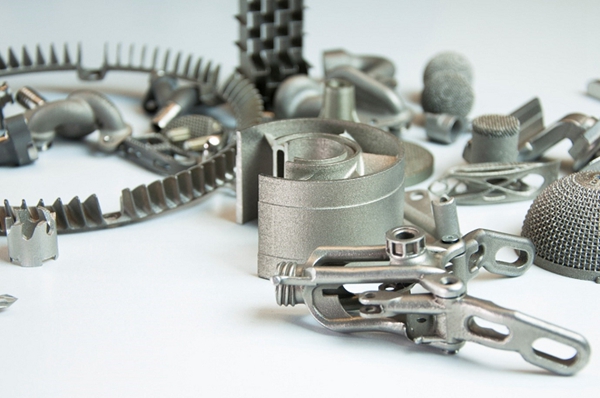

△Metal3DPrint parts

Working together to promote the future development of the aviation industry

BEAMITparent companySandvikBy transforming traditional basic steel into expensive steel3DProducts such as printing powders, spare parts and finished parts have become potential leaders in the development of business operations for companies.3DThe printing area brought outstanding performance. with3DThe continued application of printing technology in the aviation industry,Sandvikof3DPrinting powders and materials will become an important part of the manufacturing of aerospace components and engines, promoting the future development of the aviation industry.

△Adopt3DSchematic of a light engine developed using printing technology

As one of the few companies in the world that can manufacture aircraft engines,PERSONpartners includeGE、Alliance Engines、International aero enginesAndPratt & WhitneyWaiting for company. These companies collaborate competitively to jointly develop cutting-edge technologies and form joint ventures to share costs and risks. In a context of high costs linked to the development of aerospace components and cooperation on new engines,PERSONAndBEAMITWe hope to work together to create lightweight, cutting-edge components that will drive the future development of the aviation industry. Especially in the areas of low pressure turbines, maintenance, repair and overhaul.

These cooperations are important for GermanyPERSONItalianBEAMITand SwedishSandvikThey are all of significant significance and are jointly committed to promoting the future development of the aviation industry. These collaborations will not only be of great help to the additive manufacturing operations of these companies, but will also play an important role in cross-border defense and aerospace transactions. Therefore, this cooperation will further strengthen the position of the European aviation industry and promote its competitiveness on a global scale.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.