Mohou.com Concise Digital Manufacturing Manual (1): Why Use Digital Manufacturing?

Mohou.com Concise Digital Manufacturing Handbook (2): Comparison between Additive Manufacturing and Subtractive Manufacturing

Mohou.com Concise Digital Manufacturing Handbook (3): Understanding Basic Materials

Mohou.com Concise Digital Manufacturing Handbook (4): Exploring 3D Printing

Concise Digital Manufacturing Manual Mohou.com (5): CNC Machining of Subtractive Manufacturing

Foreword: “Mohou.com Digital Manufacturing Concise Manual” will briefly introduce various3DPrinting process, CNC machining (CNC), the rapid injection molding technology used in laser cutting and digital manufacturing, as well as a comparison of their advantages and disadvantages and their application in different product life cycles, and how to use each process to put the products to the market more quickly.

In this chapter we will learn how to:

▶ Start the product lifecycle

▶ Understand the product development process

▶ Choose the appropriate process

▶ Transform the prototype into a product

▶ Get products to market quickly

▶ Understand the rest of the product life cycle

So-called digital manufacturing refers to the use of computer digital control capabilities to control processing and manufacturing processes, thereby transforming traditional labor-intensive manufacturing into more efficient and precise modern manufacturing . Digital manufacturing means higher productivity, faster production cycles, less waste, more powerful processing capabilities and greater cost advantages. This chapter will briefly introduce digital manufacturing, show the different processes and steps involved in digital manufacturing, help you understand the basic knowledge involved in starting digital manufacturing, and explain why a product needs to go through several processes from design to marketing.

At the beginning of the product life cycle

For many people, developing a new product and bringing it to market is extremely exciting. Although several paths can be taken to achieve this, it typically involves several different steps, particularly where digital manufacturing capabilities are available.

The first step is to have an idea of the product you want to market. It doesn’t matter whether you have a general idea or a specific idea, whether you are a solo inventor or working for. a big company. What is important is that you are confident that your ideal product is worth the time and effort required and will eventually be brought to market. With this confidence, your product idea can be considered for the next step.

conceptual model

Generally speaking, product development starts from product drawings or computers.3DModeling begins. computer3DModels are often produced quickly and can even be used for some virtual analytical simulations. After confirming the basic digital model in the computer, it is time to build a physical model demonstrating the product concept. This mockup is generally non-functional, its main purpose is to give a general impression of what the finished product might look like.

Conceptual models allow you to evaluate feedback within the company and conduct a preliminary market analysis to assess whether the product will appeal to consumers. Creating conceptual models is necessary and effective because most people understand a real physical object much more easily than an abstract concept. If internal company feedback and market analysis produce positive results, you may consider moving to the next stage of the product life cycle.

Functional model (composition, assembly and functional verification)

Although a conceptual model can give you a rough idea, a rough picture of what your product will look like. But it’s probably still a long way from being a finished product, and at this point, it’s not something people will actually want to buy. In order to achieve the goal of the finished product, you need to design and produce more advanced functional models that can further test the shape of the product parts, its assembly, and determine whether it can meet the designed functions.

This requires that you first use3DComputer-aided design software to create a target product3DMockup, this digital model must contain all the parts and is a drawing that can be used by the manufacturer to make your finished product. You may want to choose one that can3DManufacturers perform technical analysis of model files to determine whether parts can actually be manufactured as intended and to recommend the best manufacturing options for your needs.

For example, parts must be built layer by layer using3DWhen printing, you always start with a solid block of material and cut off the excess.CNCMore suitable? It depends on the geometry of the part, volume, materials used, cost, urgency and several other important factors.

It may take a few iterations before you’re happy with every inch of the finished product, and while it may seem a bit exhausting and finite, it’s an important step in the product lifecycle.– You don’t want to put your product into actual production and then discover major design flaws, in which case you’ll have to pay a higher price.

small batch production

Once you have completed initial prototype testing, you can start thinking about starting low-volume production. Even products that eventually reach the mass market and can be produced in large quantities often start with small batches to get the product to market more quickly.

Companies with expertise in digital manufacturing, like Mohou.com, may be your best choice for low-volume production because they can provide the fast turnaround time you need to beat your competitors to market. Especially for niche products in niche markets, it is important to choose a professional manufacturer who can handle everything from concept models to low-volume production.

development of interactive products

Few products are perfect on the first iteration; In most cases, you may need several iterations to refine and improve the product, and you may find that the product must go through several versions of the design. Obviously, starting with a small number of prototypes in this case will make it easier for you to participate in this iterative development process.

Compared to traditional mass manufacturing, rapid digital manufacturing enables prototype manufacturing to have lower thresholds, lower costs and more flexibility. After all, who can guarantee success the first time?

Another common situation during product development is the discovery that the product may be used in unexpected ways or have new uses. These new uses can lead to different ways of thinking about how products should be manufactured and sold. For example, you may find that there is unexpected demand for your product in a slightly different target market, and meeting those demands may lead you to change the materials or design.

Use different digital manufacturing processes

Digital manufacturing typically does not use a single material or process. Instead, it is common to use several different processes and materials at different stages of development and production. You may choose processes and materials that are cheap but not suitable for the finished product to make very early parts to achieve the overall appearance of the product. Since these first parts can be cheap and produced quickly, you can easily make multiple iterations. Until you are satisfied with the shape, fit, appearance and function of the product.

Subsequent chapters of this book provide a more in-depth look at the processes and materials used in digital manufacturing. In short, some parts are suitable for additive processes, i.e. use.3DThe proof is made up of layers of material on top of each other and some parts are adapted for subtractive processes, that is, from a large piece of solid material to turning, milling, grinding and other mechanical processing to finally become a product. Some parts may even be only. suitable for injection molding, depending on the range of materials used. Can range from low strength plastics to extremely high strength metals.

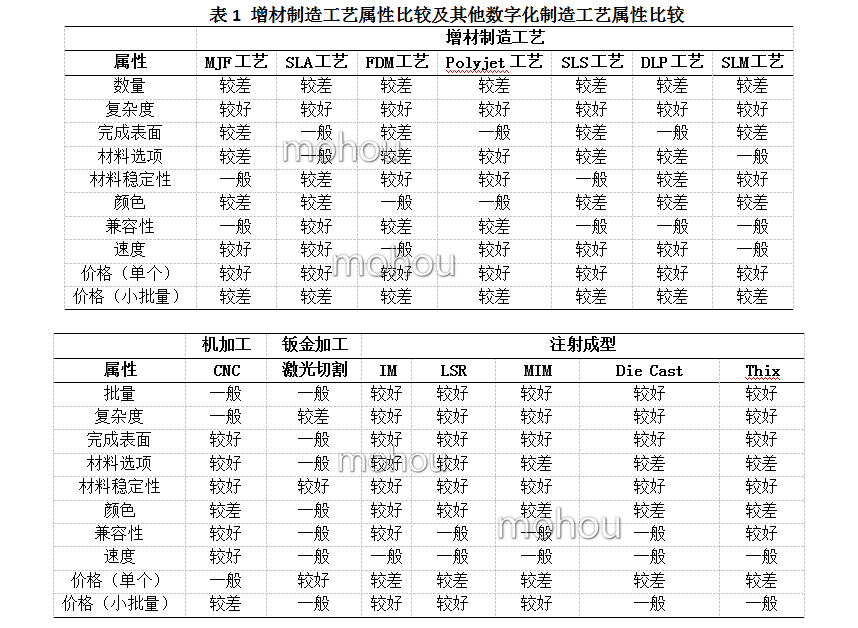

Your chosen digital manufacturing partner, such as Mohou.com, should be able to discuss with you the best processes and materials to use at each stage of product development and production. The figure below summarizes some of the properties of digital manufacturing processes (table1) for readers’ reference.

Get products to market quickly

One of the biggest benefits of digital manufacturing is the speed with which new products can move from concept to market. In traditional manufacturing, it can take weeks or even months for a machine shop or other supplier to produce a simple part for your product. But in today’s competitive market, those weeks or months of waiting can mean you’re unable to get your product to market quickly enough, and the result could be a loss of market share or even a missed opportunity.

Unlike traditional manufacturing, digital manufacturing involves very fast response times. If you choose to work with a knowledgeable and professional digital manufacturing partner, you may be able to reduce part production time to a day or even a few hours, instead of several weeks to produce a small number of machined parts. In a market where competition is brutal and fierce, first-mover advantage is crucial. In many cases, the first product to market means success, while late products can lose their opportunity forever.

From prototype to product

After a few iterations, your product may be ready to move from prototype to actual production. Depending on your needs, this transition may involve simply ordering new production parts from your digital manufacturing partner, or it may involve moving to a more traditional manufacturing process. Additionally, this change involves choosing the right manufacturing method, whether it is injection molding, machining,3D Printing or other types of processes.

Sales volume should play a decisive and important role at this time. A product that is expected to sell only a few hundred units will almost certainly require a different process than a product that is expected to sell millions of units.

Even if your analysis shows that there will be a huge market for your product and sales are expected to be huge, digital manufacturing can play an important role in this case.——Allows you to quickly enter trial production. In this case, a professional digital manufacturer can provide transition tools within a few days, start small batch trial production, and prepare real mass production tool molds at the same time. This batch preparation process typically takes several months. Digital manufacturing can help you fill this gap during this time.

After product launch

Usually, a product must be continually developed, improved and upgraded throughout its life cycle.Although making changes using traditional manufacturing processes can be difficult and expensive, low-volume products made using rapid digital manufacturing processes are much easier to adjust and modify after release.

For example, if you have an injection molded plastic part, In traditional manufacturing, the part would be produced using a very expensive steel mold, while prototype manufacturing and low-volume digital manufacturing could produce the same part using an aluminum mold , which costs a fraction of the cost of a steel mold. Although aluminum molds are not as durable as steel molds that can produce millions of repetitive parts, the savings from aluminum molds are enormous for products that produce only a few thousand or tens of thousands of items.

For products that only need to be manufactured in small batches throughout their life cycle, digital manufacturing may be the best process choice for multiple stages from design to manufacturing.

Product growth and maturity

Growth in product demand is unpredictable. If you are too optimistic about expanding production, you may end up with large and expensive inventory (warehousing, shipping, maintenance, etc.) rather than a growth spurt. Start the market with small batch digital production and gradually expand the production scale as product demand increases, thereby better controlling costs. Small batch digital manufacturing allows you to accurately specify the quantity of product required during market expansion and respond accurately to the market. and quickly.

When your product reaches the pinnacle of the market, admire the pinnacle for as long as possible“Beautiful views,” but never to the point of becoming a dangerous indulgence. You must be constantly vigilant, constantly examining market conditions, competition, consumer interests and of course demand. After all, no product can stay on top forever, which is important in determining when to start reducing production.

An important part of managing a product’s lifecycle is determining when to begin developing its successor. If a product is truly in a state of continuous development throughout its lifecycle, there may already be a framework on which to build the next version. The start of the life cycle of a new version does not depend on a specific stage of the existing product version, but depends on various market factors in the process of growth and maturity. In reality, generally, as the scale of the new version increases, the old version is gradually retired. Then the production paths of the two versions of the product will form an intersection curve.

decline

Falling off the high of a product can seem just as difficult as upselling it. When a product begins to decline, the initial excitement surrounding the product launch usually disappears. The most important question to ask is therefore how to exit the product in a rational manner. Perhaps low volume injection molding was used in the early stages of product development and growth, or perhaps the product was never low volume injection molded and went straight from prototyping with large volume steel molds. Anyway, just in time (Just in time) Manufacturing is increasingly used and integrated into production planning.

In the product decline and downsizing phase, it is also possible to resume digital manufacturing tools, allowing customers to place orders in small batches, so that there is no need to stock a large number of parts and there is an opportunity for processing. unused raw materials as digital manufacturing can be very good Fulfill small batch orders on demand. Reducing risk during product decline is an integral part of successful product lifecycle planning because it has a direct impact on a product’s P&L.

For any product, developing a robust process throughout its life cycle and using the correct manufacturing processes during that process can help increase a product’s success and create more value economic and social.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.