Benefit fromLoramendiAndvoxeljetCooperation with BMW (BMW) The Landshut factory is now capable of 3DPrint large sand cores to cast cylinder heads for high-output engines.3DNew technology for sand core printing voxeljet(NASDAQ:YEAR) marks an important milestone for the company as the partnership expands its collaboration with the world’s largest automakers, BMW It is also an important step for the latter which is increasingly implementing additive manufacturing. (AM) Business automation.

2022 Year 5 moon24The same day, Mohou.com learned that BMW announced the completion of the industrialization and digitalization of additive manufacturing. (EXECUTION) Metal laser powder bed fusion project (LPBF) Automated printing, finishing and shipping of parts. This latest industrialization of basic printing (PEAK) The project applies a similar approach to sand cores 3D for printing, for castingBMWB48 engine cylinder.

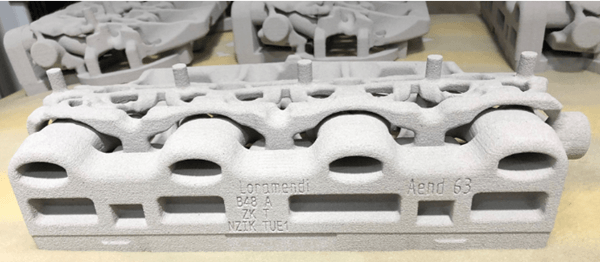

△Use voxeljet Made with technology 3D Printing sand core

Additive manufacturing is the manufacturing method of choice for automobile manufacturers due to its ability to optimize cylinder head design, increase engine efficiency and reduce consumption. However,3D Sand core printing requires various labor-intensive steps, including preparing and recycling raw materials before printing, as well as drying, removing, and cleaning the printed parts after the job is completed . To streamline the process, the partners developed an automated production line equipped with voxeljet of VX1300-X printer and Loramendi microwave curing.

△Rendering of BMW sand core production line

Loramendi Andvoxeljet HAS 2019 the year begins with ASK Chemical Products Develop together PCI who developed a binder that reduces post-processing of sand cores. The production line consists of robotic arms that can automatically voxeljet Take it out of the machine 3D The printed sand core is transferred to the curing unit and then moved to Loramendi Microwave curing machine for finishing. With the new settings,BMW Landshut The factory is capable of producing thousands of units per week 3D Print the sand core.

Although this represents BMW’s adoption of 3D Automating the printing and production of metal parts is another step forward, but it also relies on voxeljet Building on continued success in the automotive sector. Also,voxeljetThe company’s American customers International tools and equipment also started using3D Printed Sand Cores for Cadillac CELESTIQAutomotive Mass Produces Large-Format, Weight-Reducing Structural Components, Here’s an Estimated Selling Price 300,000 limited edition luxury car in dollars.

△VX4000 3D Model Print the sand core. Photo by Tools & EquipmentInternational (TEI) provide

Due to the small application market of the technology,voxeljet The stock price appears to be in trouble since its listing. Major automakers now use sand cores on a large scale 3DPrinting for mass production, it can bounce back, but it can also be Metal deskacquisition.

According to Mohou.com, sand mold in China3DThe printing metal casting business has also developed rapidly in recent years. The traditional smelting industry has been banned or driven out in many places due to pollution and other problems. But add sand mold3DAfter the introduction of printing technology, it has become a green industry and has been well received by the market and the government.

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.