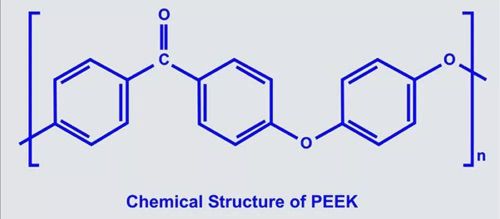

In addition, the amount of bacterial colonization on the surface of PEEK materials is lower than that of pure titanium, and their biological safety is reliable. Its composite material has an elastic modulus similar to that of human bone tissue, making it widely used in the medical field. Research on PEEK in the form of implants, temporary abutments, fixed prostheses and removable denture supports has gradually developed, and its application in the field of oral medicine has attracted the attention of researchers at home and abroad .

Presentation of PEEK

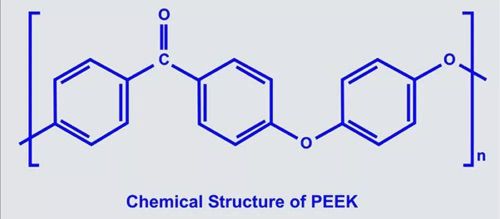

The elastic modulus of unmodified PEEK is 3-4 GPa, and the elastic modulus of modified PEEK can reach 18-150 GPa, which is very close to the elastic modulus of human bone tissue. Some researchers believe that using implants with an elastic modulus similar to that of bone tissue is beneficial in reducing the stress shielding effect.

The surface energy of PEEK is low, which is not conducive to cell adhesion, the osteogenic effect is poor, and it is difficult to achieve ideal results when combined with conventional treatment methods. . At the same time, PEEK is dark in color, and its direct use as an intraoral restoration affects the appearance to a certain extent, so its color needs to be adjusted.

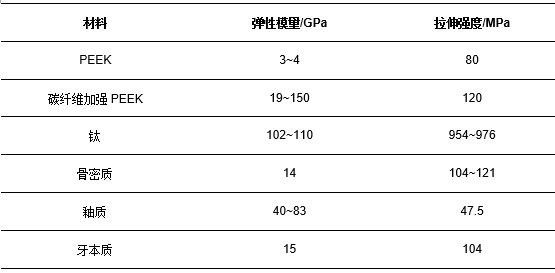

In order to overcome the above disadvantages and improve the performance of PEEK, many researchers have carried out surface modifications by group introduction, particle filling, fiber reinforcement, plasma spraying, spin coating, etc., in order to obtain better clinical application results.

Application of PEEK in the field of dental implants

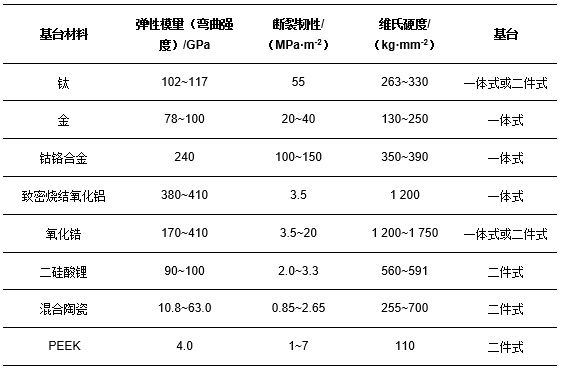

In the 1960s, intraosseous dental implants were mainly made of pure titanium and titanium alloys (such as Ti-6Al-7Nb, Ti-6Al-4V, etc.). Although titanium implants are supported by a large body of experimental and clinical evidence, there are still some problems with their clinical use. One is the potential sensitization of titanium; secondly, compared with human bone tissue, the elastic modulus of titanium is too high, and reconstruction or loss of bone tissue is likely to occur; third, metal implants lack light transmission, which affects their appearance.

In 1998, the British company Invibio launched PEEK implants. With the advent of commercial PEEK implants, related research has gradually developed. PEEK and its modified materials have good performance. Some researchers believe that PEEK implants can avoid the stress shielding effect and can even replace metal implants in plastic surgery, trauma surgery and other fields.

Mechanical resistance

One of the main problems encountered by PEEK implants in their application is their low capacity to resist stress, i.e. insufficient mechanical strength. The emergence of reinforcement materials such as glass fiber reinforced PEEK (GFR-PEEK) and carbon fiber reinforced PEEK (CFR-PEEK) has improved the mechanical strength of PEEK to a certain extent.

Lee et al. conducted a study on the stress protection and fatigue limit of PEEK implants. The results showed that the fatigue limit of the 4 mm diameter GFR-PEEK implant was 310 N and its static compressive strength was 256 N. The implant was sufficient to resist the biting force cyclic of the anterior teeth (140-170N).

Osteointegration

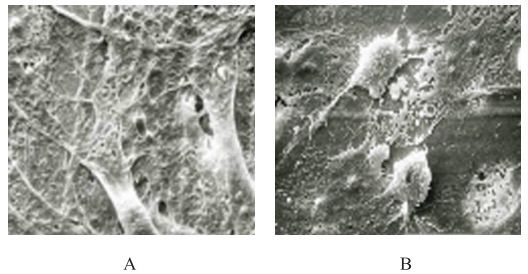

As an inert material, PEEK has little interaction with surrounding tissues. Some researchers have conducted a series of cellular experiments on PEEK. The results show that in terms of promoting cell proliferation, compared with titanium, the proliferating cells on the surface of PEEK exhibit stronger inflammatory proliferation and more obvious fibrous interactions with bone tissue.

Cook et al. studied the bond strength between PEEK implants and single-layer bone (unicortical bone). The results showed that when the implants were implanted at 4 and 8 weeks, the titanium-coated implants showed a significant increase. contact report.

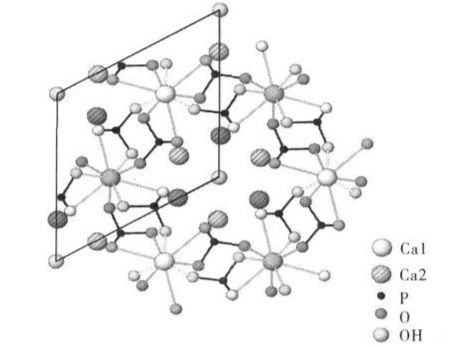

In order to improve the interaction between PEEK implants and surrounding tissues, surface treatment of PEEK is one of the effective methods. Increasing surface roughness can promote cell adhesion; In addition to titanium coating, surface coating PEEK with materials such as hydroxyapatite or calcium phosphate can promote osteoblast proliferation.

PEEK pillar

Some researchers have compared the mechanical properties of PEEK and titanium temporary abutments. The results show that the force exerted during the rupture of the temporary PEEK abutment is (329.4 ± 103.6) N. Although it is much lower than that of the temporary titanium abutment, it can withstand the impact . on the anterior teeth. Thanks to its good biocompatibility, PEEK can be used as a healing pillar.

Hahnel et al. investigated the bacterial adhesion rate of commonly used abutment materials such as titanium, zirconia, PEEK, and polymethyl methacrylate (PMMA). The results showed that the adhesion rate of plaque on the PEEK surface was significantly different from that of titanium and polymethyl. methacrylate or PMMA pillars are similar or even inferior.

Compared to titanium or zirconia abutments, PEEK abutments are easier to cut. Additionally, PEEK can also be used as a superior support material for implant restorations. When used with gingival-colored materials, it can reduce the weight of the restoration while ensuring the red aesthetic effect. PEEK can therefore be used as an alternative material to metal or porcelain for implant abutments.

Application of PEEK in the repair of removable prostheses

The clasp is an essential element of the removable prosthesis. The retention of the removable prosthesis relies mainly on the elastic holding force of the clasp on the abutment teeth. Traditional snap rings are made of alloy and have the advantages of good elasticity, good retention and flexibility. Compared with metal clasps, tooth-colored clasps reduce the impact of the clasp on the appearance to a certain extent. They are usually made of thermoplastic resin, and PEEK is one of them.

Some researchers have studied the retention strength of clasps made from different resin materials. Use PEEK and polyetherketoneketone respectively[poly(ether-ketone-ketone),PEKK]The three-arm clasps are made of polyformaldehyde (POM) and the chewing simulator performs 15,000 insertion-dislocation cycles on each clasp in a liquid environment.

The research results show that the retention force of PEEK clasp is higher than that of the other two materials and does not decrease significantly with shrinkage and wear, but its retention force is much lower than that of plastic clasp. cobalt-chromium alloy in addition to cobalt; visible under a scanning electron microscope. The chrome alloy clasp caused surface wear of the pillar model, while the resin clasp did not wear the pillar model.

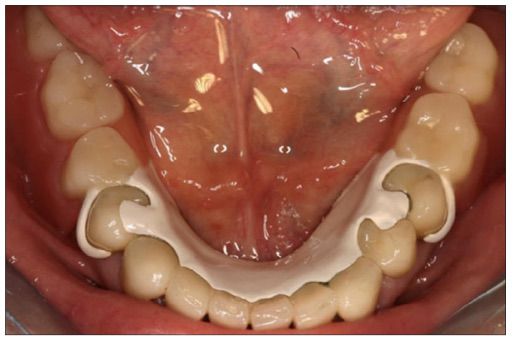

Zoidis et al. reported a case of removable mandibular partial denture made of PEEK as scaffolding material because the patient was not satisfied with the taste, weight and color of the metal clasp. They made the molten PEEK material into a carrier by vacuum casting, then arranged the teeth and made a resin base on it.

Compared to removable prostheses with traditional cobalt-chrome alloy frames, the weight of removable prostheses with PEEK frames is reduced by 27.5%. Since PEEK has good elasticity, the design of the clasp and mesial bracket is conducive to reducing distal stress on Ken’s Class I abutment teeth. Therefore, PEEK can be used as an alternative material to metal stents for metal-sensitive patients who cannot tolerate metal in the mouth.

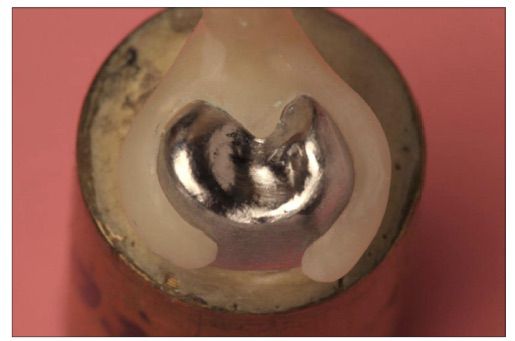

Application of PEEK in the restoration of fixed prostheses

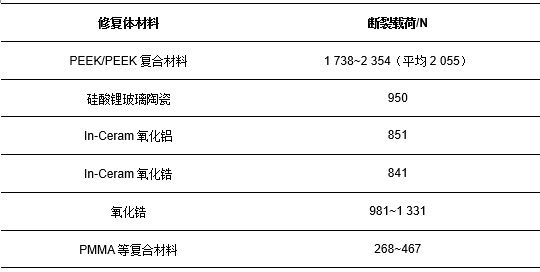

Stawarczyk et al. studied the fracture resistance of 3-element PEEK composite fixed bridges with different manufacturing processes (CAD/CAM cutting, spherical PEEK die casting and granular PEEK die casting). The results show that the fixed bridge made by CAD/CAM cutting has the highest breaking strength, with a breaking load of 2,354 N; the granular die-cast restoration has the lowest breaking load, with a breaking load of 1738 N.

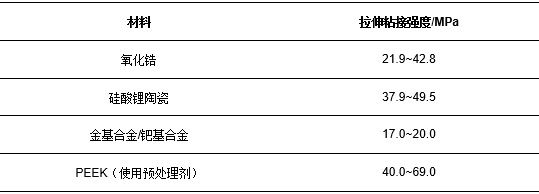

Whether used directly as a restoration or crown, PEEK and its composites face bonding issues with abutment teeth or surface materials. Therefore, many researchers perform surface treatment on PEEK or apply different bonding systems, starting from two perspectives: increasing the mechanical retention force and chemical interaction, so as to improve its bonding performance.

Some researchers pretreated the PEEK surface before bonding and applied pretreatment agents at the same time. The results showed that after sandblasting treatment (50 μm, 0.2 MPa), the two pretreatment agents Visio.link and Signum PEEK BondⅠ+Ⅱ can significantly increase the bond strength. between resin and PEEK, reaching 40.0~69.0 MPa and 41.3~57.5 MPa respectively.

Uhrenbacher et al. studied the effects of different surface treatments on the retention force of single PEEK crowns. The results show: PEEK single crown without any treatment[使用的粘接剂为自粘接树脂(RelyX Unicem,3M ESPE)]The retention force with natural abutment teeth is (0.43 ± 0.24) MPa. After sandblasting and using the Signum PEEK Bond system, the retention force increases to (2.97 ± 0.92) MPa.

At present, PEEK and its modified materials commonly used in dentistry are mostly gray or white and have no light transmission, so they are not suitable for restorations in areas with high aesthetic requirements such as the area of the anterior teeth. For this reason, veneers are often required on PEEK crowns. The most common PEEK coating is composite resin.

Conclusion

With its physical and chemical properties similar to oral hard tissues, PEEK can be used as a substitute for traditional dental materials in areas such as restoration and implantation. At present, the application of PEEK is mainly in the laboratory research stage, and much research is devoted to improving its mechanical strength, biocompatibility, bonding performance, etc. Widespread application of PEEK restorations in clinical practice requires more research data from animals. support for experiments and clinical trials.

Some references:

[1] Korabi R., Shemtov-Yona K., Rittel D. On stress/strain protection and the material stiffness paradigm for dental implants[J]. Clinical Implant Dentistry and Related Research, 2017.

[2] Al-Rabab’Ah M, Hamadneh W, Alsalem I et al. Use of high-performance polymers as abutments and frameworks for dental implants: report of a case series[J]. Journal of Prosthodontics, 2017, 28 (Suppl 11).

[3] Wen H, Xing L, Wei C. Review on Research on Modification and Application of PEEK Composites[J]. Application of engineering plastics, 2017.

[4] Al-Rabab’Ah M, Hamadneh W, Alsalem I et al. Use of high-performance polymers as abutments and frameworks for dental implants: report of a case series[J]. Journal of Prosthodontics, 2017, 28 (Suppl 11).

[5] Schwitalla AD, Abou-Emara M, Zimmermann T, et al. The Applicability of PEEK Based Abutment Screws[J]. Journal of Mechanical Behavior of Biomedical Materials, 2016, 63: 244-251.

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.