Optimizing CNC Machining for Radiator Parts: Tips and Best Practices

In the world of industrial manufacturing, CNC machining is a crucial process that requires precision, efficiency, and attention to detail. When it comes to producing radiator parts, selecting the right materials, understanding design nuances, and harnessing the capabilities of your CNC equipment are key factors in delivering high-quality products that meet customer expectations. In this article, we’ll delve into the importance of these factors and provide valuable tips for optimizing CNC machining for radiator parts.

Choose the Right Material

When selecting a material for CNC machining radiator parts, thermal conductivity and machinability are crucial considerations. That’s why aluminum and copper are popular choices. Both materials possess remarkable thermal conductivity, which is essential for effective heat transfer in radiators. Additionally, they are relatively easy to machine, making them ideal for CNC machining.

However, it’s essential to ensure that the material you choose matches the intended use of the radiator. For instance, if the radiator is designed for high-temperature applications, you may need a material with enhanced thermal conductivity, such as pure copper or a copper alloy. On the other hand, if the radiator is intended for low-temperature applications, a less expensive aluminum alloy might be sufficient.

Understand the Design Nuances

The design of the radiator part is equally important. Complexity can be a significant factor in determining the quality of the final product. When dealing with intricate shapes, it’s essential to plan the machining process meticulously to achieve the desired accuracy.

To simplify the process, many manufacturers rely on Computer-Aided Design (CAD) software to simulate the machining process. This simulation allows for the detection of potential issues before production, enabling designers to make necessary adjustments and perfect the design.

Harness the Capabilities of Your CNC Equipment

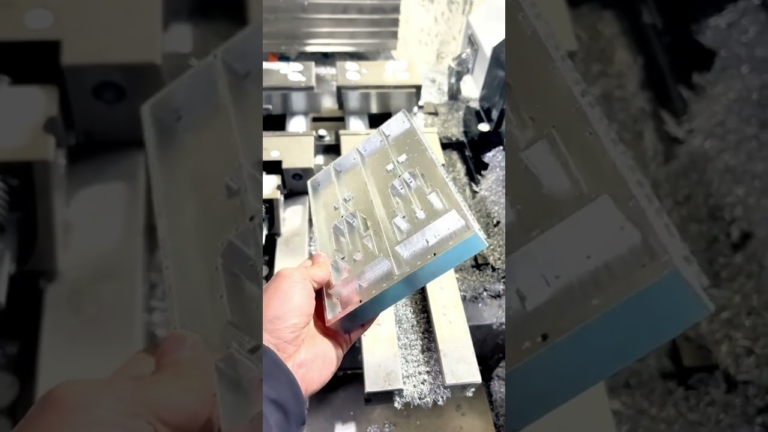

The third critical factor in optimizing CNC machining for radiator parts is the utilization of your equipment’s advanced features. At GreatLight CNC Machining, we’re proud to offer some of the most advanced 5-axis CNC machines, capable of producing parts with remarkable accuracy and precision.

These machines enable us to reduce lead times and improve the quality of our radiator parts, ensuring they meet even the most stringent customer requirements. By leveraging the capabilities of your CNC equipment, you can achieve similar results, resulting in a better final product.

The Importance of 5-Axis Machining

5-axis CNC machining is a game-changer in the world of precision manufacturing. This advanced technology enables the production of complex shapes and contours with enhanced accuracy, making it an ideal solution for radiator parts.

The 5-axis CNC machines at GreatLight CNC Machining are equipped with advanced features, such as programmable interpolators, differential encoders, and high-resolution linear scales. These features allow for the production of parts with tolerances as low as 0.010mm, making them ideal for applications where precision is paramount.

Tips for Efficient CNC Machining of Radiator Parts

- Choose the right material: Select a material that matches the intended use of the radiator, considering factors such as thermal conductivity and machinability.

- Understand the design: Plan the machining process carefully, using CAD software to simulate the process and detect potential issues before production.

- Leverage advanced equipment features: Utilize the capabilities of your CNC equipment, such as 5-axis machining, to improve accuracy, reduce lead times, and enhance overall production.

- Maintain a clean and organized shop: Keep your workshop organized and well-lit to reduce errors and improve productivity.

- Develop a comprehensive quality control process: Establish a quality control process to ensure that every part meets customer requirements, reducing the likelihood of rework and improving overall efficiency.

- Stay up-to-date with industry developments: Remain informed about the latest advancements in CNC machining, staying one step ahead of the competition and ensuring your company remains competitive.

- Collaborate with suppliers and customers: Work closely with suppliers to source high-quality materials and with customers to understand their needs and requirements, ensuring that your products meet their demands.

- Invest in employee training: Provide ongoing training for your employees to ensure they’re equipped with the skills necessary to work with advanced CNC equipment and software.

- Implement lean manufacturing principles: Adopt lean manufacturing methods to reduce waste, improve efficiency, and increase overall productivity.

- Monitor and analyze production data: Keep track of production data to identify areas for improvement, making data-driven decisions to optimize your CNC machining process.

By following these tips and best practices, you can optimize your CNC machining process for radiator parts, ensuring the production of high-quality products that meet customer expectations. At GreatLight CNC Machining, we’re committed to providing the highest level of precision and sophistication in our CNC machining services, and we’re always here to help you achieve the same level of excellence in your own manufacturing operations.

Contact Us

If you’re interested in learning more about our CNC machining services or would like to discuss your radiator part needs, please don’t hesitate to contact us at [email protected]. Our team of experts is dedicated to providing the utmost support and guidance, helping you navigate the world of CNC machining with confidence.

Conclusion

In conclusion, optimizing CNC machining for radiator parts requires a comprehensive approach, encompassing the selection of the right materials, understanding design nuances, and leveraging the capabilities of your CNC equipment. By following these tips and best practices, you can ensure the production of high-quality radiator parts that meet customer requirements and set your company apart in the market. At GreatLight CNC Machining, we’re committed to delivering exceptional results, and we’re always here to support your CNC machining needs.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.