The Revolution of 5-Axis Machining: Unlocking Unprecedented Manufacturing Freedom

For decades, CNC machining pushed boundaries within three linear dimensions. Today, 5-axis machining represents a quantum leap, transforming workshops into hubs of unparalleled precision and complexity. By simultaneously maneuvering tools or workpieces across five independent axes, this technology transcends conventional limitations, enabling geometries once deemed impossible. Discover how this advanced approach is reshaping manufacturing paradigms.

Demystifying the Axes: Beyond X, Y, and Z

All CNC machining starts with the fundamental linear axes X, Y, and Z:

- X-axis: Left-to-right movement

- Y-axis: Front-to-back movement

- Z-axis: Up-and-down movement (typically spindle approach)

3-axis machining uses these paths to create intricate 3D shapes efficiently, ideal for parts without extreme undercuts or deep cavities requiring multi-angle access. However, complexity demands more freedom.

5-axis machining introduces two rotational axes—A, B, or C—operating in conjunction with X, Y, and Z:

- A-axis: Rotation around the X-axis (tilting forward/backward).

- B-axis: Rotation around the Y-axis (tilting side-to-side).

- C-axis: Rotation around the Z-axis (rotating horizontally like a turntable).

This kinematic symphony allows the cutting tool to approach the workpiece from virtually any angle within the machine’s working envelope without needing manual repositioning. The rotary movement can be applied to the tool (via a tilting spindle head), the workpiece (via a rotary table), or both.

The Power of Configuration: Tailoring 5-Axis to Your Needs

Machines achieve 5-axis motion through distinct mechanical configurations, each with unique advantages. Here’s a breakdown:

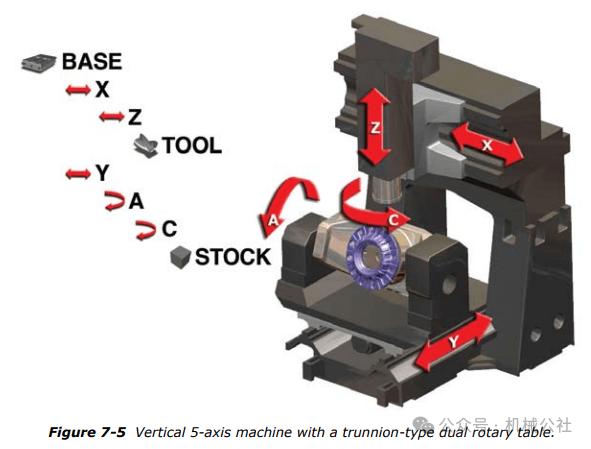

Table/Table Configuration

- Mechanism: Features two stacked rotary tables mounted on the machine bed. The workpiece is secured to the top table.

- Movement: Both rotary axes (commonly A and C, or B and C) are executed by the tables, physically rotating the workpiece relative to a fixed vertical spindle.

- Ideal For: Small to medium-sized parts, intricate details requiring continuous rotational access, high precision applications like medical implants or watch components.

- Consideration: Smaller work envelope due to stacked tables; workpiece weight limits apply.

Head/Head Configuration

- Mechanism: Uses a fully articulated spindle head capable of tilting and rotating (typically A and B axes). The workpiece remains stationary on a standard table.

- Movement: All rotations occur at the spindle head, positioning the cutting tool at any angle above the fixed workpiece.

- Ideal For: Large, heavy, or asymmetrical parts (e.g., aerospace structural components, molds, marine propellers), high-volume production.

- Consideration: Requires highly rigid spindle head; clearance around the head can limit access in tight spaces.

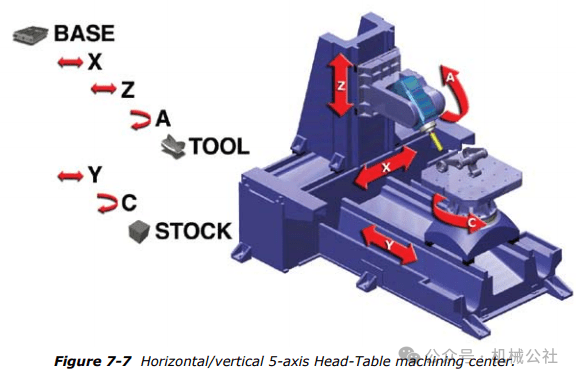

- Head/Table (Hybrid) Configuration

- Mechanism: Combines a tiltable spindle head (usually B-axis) with a rotary table (C-axis) on the machine bed. Offers the most flexibility.

- Movement: Rotation is shared. The table rotates the workpiece (C-axis), while the head tilts the tool (B-axis), enabling complex compound angles.

- Ideal For: Versatile machining of medium to large parts, optimized tool approach angles, high accuracy for complex contours (die & mold, turbine blades).

- Consideration: Programming complexity is higher due to coordinated motion.

Beyond Geometry: The Transformative Benefits

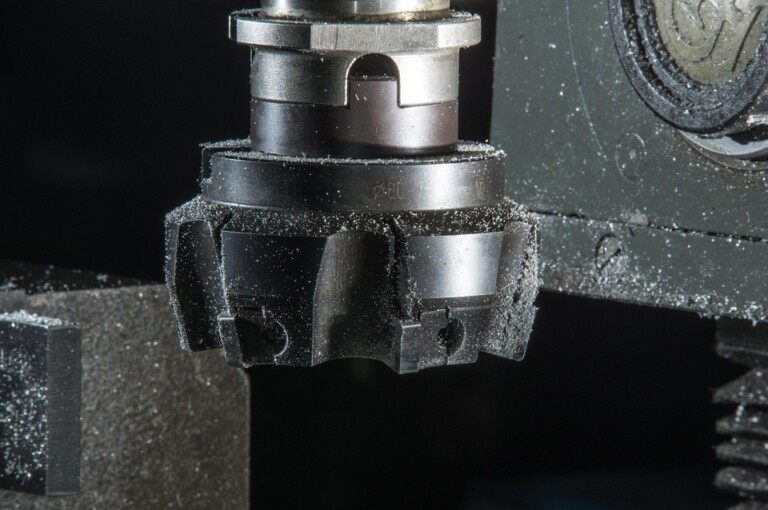

- Complexity Unlocked: Manufacture previously "unmachinable" parts—impellers with shrouded blades, turbine blisks, intricate surgical tools, compound-curved aerospace structures.

- Dramatically Reduced Setups: Complete parts in a single fixture window. Eliminates manual repositioning errors and drastically cuts non-productive time.

- Superior Surface Finishes: Maintains the optimal tool contact angle ("tool vector") with complex surfaces throughout the cut, minimizing scalloping and reducing hand finishing.

- Extended Tool Life & Performance: Utilize shorter tools by improving access; maintain constant chip loads and leverage higher cutting speeds appropriate to material/tool orientation.

- Enhanced Accuracy: Minimizes tolerance stack-up inherent in multiple setups. Features machined in a single operation ensure precise geometric relationships.

- Improved Productivity: Faster cycle times via continuous cutting paths and elimination of setup changes. Produce complex parts in hours instead of days.

Where 5-Axis Reigns Supreme: Industry Applications

- Aerospace: Engine components (blisks, impellers), airfoils, structural brackets, intricate ducting.

- Medical: Orthopedic implants, prosthetics, surgical instruments requiring biocompatible contours.

- Automotive & Motorsport: High-performance engine blocks/heads, complex intake manifolds, suspension components, custom molds.

- Energy: Turbine blades (wind/hydro/gas), generator components, oil & gas valve bodies.

- Consumer Goods: High-end watch components, complex mold/die creation, consumer electronics housings.

Mastering the Future: Programming & Precision

Adopting 5-axis is an investment. Mastering CAM (Computer-Aided Manufacturing) software capable of sophisticated toolpath simulation and collision avoidance is crucial. Technicians require training to leverage its full potential and manage complex setups. Machine rigidity, calibration, thermal stability, and controller capabilities become paramount at this level of precision. When mastered, however, 5-axis machining transitions from a complex tool to a transformative competitive advantage.

Conclusion: The Indispensable Evolution

Five-axis machining isn’t simply an incremental improvement—it’s a fundamental evolution that redefines manufacturing possibilities. By breaking free from traditional three-axis constraints, it unlocks unparalleled design freedom, streamlines production, elevates quality, and minimizes waste. As demand for more complex, efficient, and precise manufacturing grows, mastering 5-axis technology transforms from a niche capability into an essential pillar of modern, agile, and competitive machining operations. The storm in the industry isn’t brewing; it’s here, reshaping the landscape one revolutionary part at a time.