The World of 5-Axis Machining: Revolutionizing the Production of Motorcycle Parts

In the high-performance world of motorcycles, precision and reliability are essential for a thrilling ride. Modern 5-axis machining has played a significant role in producing complex and intricate components with unparalleled accuracy and efficiency. In this article, we’ll delve into the world of 5-axis machining, its benefits, and how it’s revolutionizing the production of motorcycle parts.

### The Evolution of 5-Axis Machining

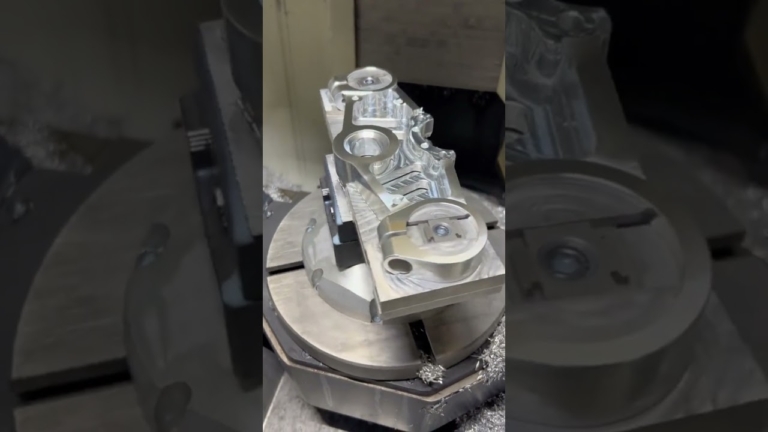

The 5-axis machining process, also known as multi-axis machining, is a production technique that utilizes computer numerical control (CNC) machines with five axes of motion instead of the traditional three. This increased flexibility allows for the automation of complex parts with intricate geometries, including curves, angles, and compound radii. The 5-axis machine can also perform simultaneous 3D contouring, 3D milling, and live tools applications, ensuring unparalleled precision and surface finish.

In the early days of manufacturing, production of motorcycle parts required significant manual intervention, resulting in longer lead times and higher costs. With the advent of 5-axis machining, manufacturers can now produce complex components with increased efficiency, reduced costs, and improved accuracy.

### The Advantages of 5-Axis Machining

In the world of 5-axis machining, the advantages are multifaceted. Some of the key benefits include:

#### 1. Increased Accuracy

5-axis machining offers higher accuracy due to its increased flexibility. With the ability to position the cutting tool on five axes, It allows for precise movements, precise removal of material, and reduced stress on the finished part.

#### 2. Reduced Material Waste

By utilizing 5-axis machining, manufacturers can reduce material waste and minimize the need for rework. This not only saves time but also reduces the environmental impact of production.

#### 3. Improved Speed

The increased flexibility of 5-axis machining enables faster production cycles, reduced setup times, and optimized workflow, resulting in faster turnaround times and increased productivity.

#### 4. Enhanced Surface Finish

The versatility of 5-axis machining allows for the production of complex surfaces, including contoured and three-dimensional geometries, resulting in improved surface finish and reduced post-processing steps.

#### 5. Increased Design Freedom

5-axis machining unlocks new possibilities in design, enabling the creation of intricate, complex, and previously unmanufacturable parts. This opens up new possibilities for innovative design and product development.

### 5-Axis Machining in Motorcycle Production

In the context of motorcycle production, 5-axis machining offers a significant advantage. Motorcycle components, such as crankshafts, camshafts, and cylinder heads, require precise machining to ensure optimal performance and reliability. The use of 5-axis machining enables the production of these components with increased accuracy, precision, and surface finish, enhancing the overall performance of the motorcycle.

In recent years, 5-axis machining has become increasingly popular in the motorcycle industry, with many manufacturers opting for this advanced technology to produce high-performance components. For example, the production of motorcycle cylinder heads with intricate coolant passages, combustion chambers, and valves can now be accurately and efficiently produced using 5-axis machining.

### Case Studies

Several significant companies have already adopted 5-axis machining for their motorcycle part production, demonstrating the benefits of this technology. For instance:

#### 1. BMW Motorrad

BMW Motorrad, a leading manufacturer of premium motorcycles, has invested heavily in 5-axis machining technology to produce complex components, such as camshafts and crankshafts. This has resulted in improved accuracy, reduced production times, and enhanced overall product quality.

#### 2. Harley-Davidson

Harley-Davidson, a renowned American motorcycle manufacturer, has also adopted 5-axis machining for the production of motorcycle parts, including cylinder heads and engine components. This technology has enabled the company to produce high-performance components with improved precision and surface finish, enhancing the overall performance of their motorcycles.

### Conclusion

The world of 5-axis machining has revolutionized the production of motorcycle parts by offering increased accuracy, reduced material waste, improved speed, and enhanced surface finish. The benefits of 5-axis machining are not limited to motorcycle production but can be applied to various industries where complex components are required, such as aerospace, automotive, and medical.

As technology continues to evolve, 5-axis machining will play an increasingly important role in the production of motorcycle parts and other complex components. Manufacturers who adopt this technology will be better equipped to meet the demands of the market, creating high-performance products with increased accuracy, efficiency, and precision. Whether you’re a motorcycle enthusiast or a seasoned engineer, the world of 5-axis machining is an exciting and rapidly evolving field that is sure to shape the future of manufacturing.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.