The world of automotive manufacturing is a complex and highly competitive field, where precision and attention to detail are crucial for producing high-quality parts that meet exacting standards. In recent years, 5-axis machining has become an essential technique for producing complex components with precision and accuracy. In this article, we’ll explore the benefits and applications of 5-axis machining in the automotive industry.

## The Need for Precision

In the world of automotive manufacturing, precision is paramount. Every component must be designed and manufactured with precision to ensure seamless assembly and integration with other parts. The slightest miscalculation or misalignment can lead to catastrophic consequences, such as reduced efficiency, increased downtime, and compromised safety.

### The Rise of 5-Axis Machining

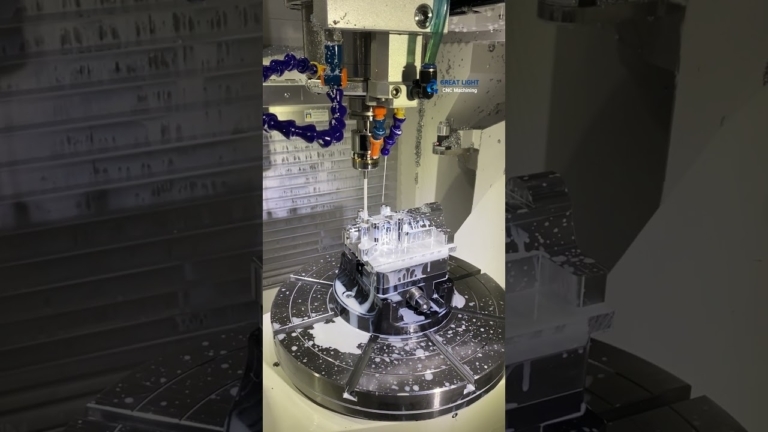

Five-axis machining is a type of computer numerical control (CNC) machining that allows for complex shapes and designs to be created with precision and accuracy. This technology has revolutionized the automotive manufacturing industry, enabling the production of intricate components that were previously difficult or impossible to produce using traditional machining methods.

### Advantages of 5-Axis Machining

So, what are the benefits of 5-axis machining? Here are a few key advantages:

#### Reduced Errors and Defects

One of the most significant advantages of 5-axis machining is its ability to reduce errors and defects. With this technology, manufacturers can precision-machined parts with unprecedented accuracy, resulting in reduced rejects and rework.

#### Increased Efficiency

Five-axis machining enables manufacturers to produce complex shapes and designs with greater speed and efficiency. This results in increased productivity, reduced lead times, and lower production costs.

#### Improved Surface Finish

Five-axis machining allows for the production of parts with superior surface finish, reducing the need for additional processing steps and increasing overall quality.

#### Increased Complexities in Design

Five-axis machining enables the production of complex shapes and designs that would be difficult or impossible to produce using traditional machining methods.

## Applications of 5-Axis Machining in Automotive Manufacturing

So, where is 5-axis machining used in automotive manufacturing? Here are a few key applications:

### Engine Components

Five-axis machining is used extensively in engine component manufacturing, including:

#### Turbine Blades

#### Crankshafts

#### Camshafts

### Transmission Parts

Five-axis machining is also used in the production of transmission components, such as:

#### Gears

#### Shafts

#### Bearings

### Suspension and Chassis

Five-axis machining is used in the production of suspension and chassis components, such as:

#### Steering parts

#### Bushings

#### Linkages

### Other Applications

Five-axis machining is also used in the production of other automotive components, including:

#### Exhaust system components

#### Body panels

#### Trim and trim components

## The Future of 5-Axis Machining in Automotive Manufacturing

As the automotive industry continues to evolve, the demand for precision and complexity is only expected to increase. As such, 5-axis machining is likely to play an increasingly important role in the manufacturing process.

### Increased Adoption of Additive Manufacturing

With the increasing adoption of additive manufacturing (AM) in the automotive industry, 5-axis machining will need to adapt to work in conjunction with AM technology.

### Improved Surface Finish and Precision

As the industry continues to push the boundaries of what is possible, 5-axis machining will need to produce parts with even greater precision and surface finish.

### Increased Complexity in Design and Manufacturing

The future of 5-axis machining will require the ability to produce even more complex shapes and designs, as well as the ability to integrate with other manufacturing technologies.

In conclusion, 5-axis machining has revolutionized the automotive manufacturing industry, enabling the production of complex components with precision and accuracy. As the industry continues to evolve, it is clear that 5-axis machining will play an increasingly important role in producing high-quality, high-performance components that meet the demands of a rapidly changing market.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.