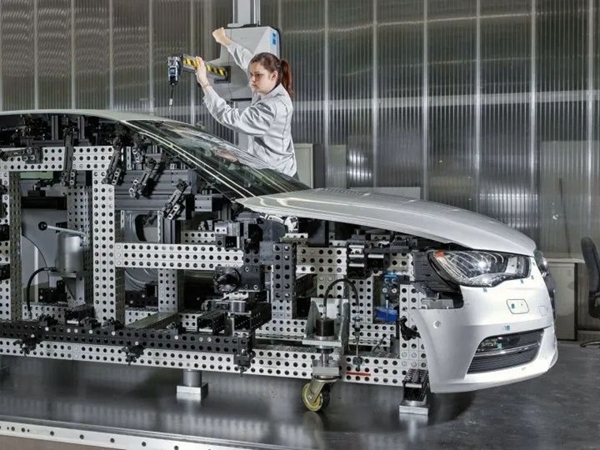

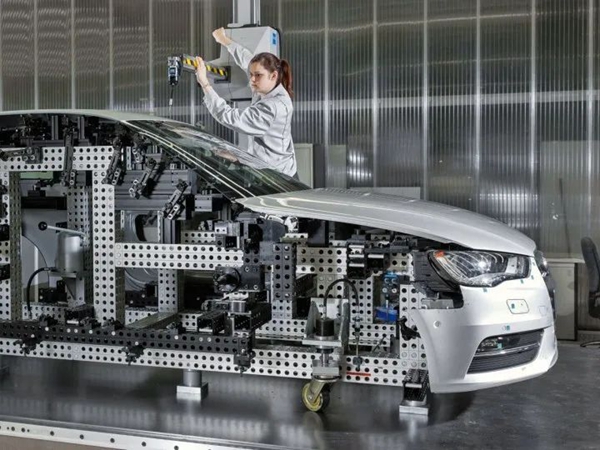

Domestic automobile industry3DPrinting has always been primarily used for modeling and test production, but in fact many of the most often overlooked applications focus on auxiliary tools in the production and manufacturing process, or what we commonly call “tools”.

According to general statistics, the number of tooling for a new model is2000About parts including80%This is a large-scale complex tool,20%It is a simple type mainly based on measuring tools. Every year, OEMs and parts suppliers spend millions on tooling. Additionally, with the launch of new models, each model requires updated tooling to meet new needs. The consumption and cost of the tools are actually the same. the number of models and the frequency of model changes.

why thenGeneral managerOne-time delivery in the United States17roundStratasys FDMHigh-tech printing equipment offers practical solutions to reduce costs and increase efficiency.

The scope of tooling applications is quite broad. Due to space constraints, this article will mainly focus on.StratasysAvailable in carbon fiber nylon12application of this material.

carbon fiber nylon12Material characteristics:

Only aluminum alloy weight1/3stainless steel1/7but can bear900 barpressure

able to cope143Ambient temperature in degrees Celsius

The main points of application of this material are as follows:4direction

△Work clothes

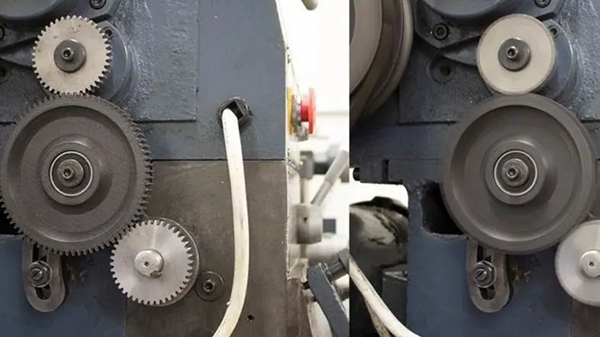

△Forming tools

△Metal spare parts

△Equipment spare parts

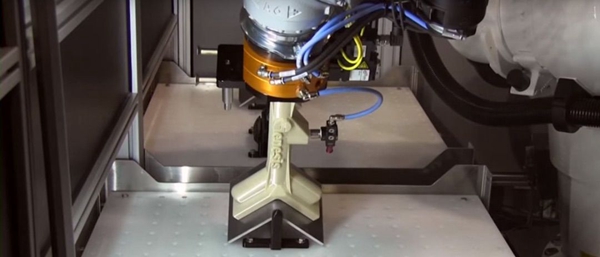

At the same time, relying onFDMCharacteristics of the production technology, it is the only additive manufacturing technology capable of producing inserts. For example, integrate sensing equipment, air ducts and cables throughout the tooling to significantly reduce the risk of damage to this sophisticated electronic equipment during on-site operations.

From a ROI perspective, the input-to-output ratio is astonishing. Let’s analyze it based on the following real cases:

Customers use carbon fiber nylon12The tooling produced is larger than600mmmetal positioning holes are integrated during the printing process and the finished product3DThe scanning accuracy is0.2mmin the beach.

The weight is only one third of that of traditional metal tools and the total manufacturing time is1months reduced to40hours, thus saving the whole process2Thousands of dollars.

By putting these numbers together and counting the robot load, money, time, beats, labor, etc. which can be saved in the whole process once the weight is reduced, the customerReturn on investmentexist1The investment will be recovered within a year and the cash flow will become positive. This app alone will save money every year.40%。

source:Stratasys

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.