Recently, according to Mohou.com, Wang Zhigang, director of the joint movement department of the Orthopedic Center of Xinjiang Uygur Autonomous Region People’s Hospital, led his team to use 3D printing technology to successfully make a replacement inverted shoulder with a custom shoulder replacement. -shoulder prosthesis made for a patient suffering from a difficult and complicated old injury to the shoulder joint. The operation resolved the problem of persistent pain and inability to move the patient’s left shoulder joint for more than 4 years.

Mr. Lan, who has suffered for many years, is 41 years old and comes from Yili. In 2019, Mr. Lan accidentally fell and injured his left shoulder joint and suffered a comminuted fracture of the proximal end of his left humerus. Repeated treatments at the local hospital always produced poor results. The doctor recommended seeking treatment at a major hospital. Ürumqi. Over time, Mr. Lan’s shoulder joint pain intensified, the mobility of the shoulder joint was limited, and the left upper limb was significantly shorter than the right, seriously affecting his quality of life. normal life.

At the end of December 2022, at the suggestion of his family, Mr. Lan went to the People’s Hospital of the Autonomous Region with the idea of trying. Zhang Haoshaqiang, deputy chief physician of the joint movement department of the orthopedic center, examined Mr. Lan and found that the patient’s left arm was significantly shortened, about 5 cm shorter than the right side. The muscles of the shoulder joint were significantly atrophied, and the patient’s left arm was significantly shortened. Shoulder joint abduction was only 15 degrees. Forward flexion is 20 degrees, posterior extension is 5 degrees, and internal and external rotation activities are obviously limited. Considering the long course of Mr. Lan’s illness and the complexity of his condition, he was admitted to the hospital to perform relevant examinations and then determine the treatment plan.

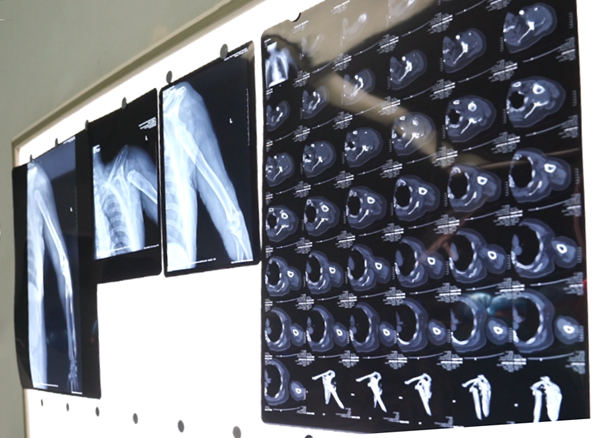

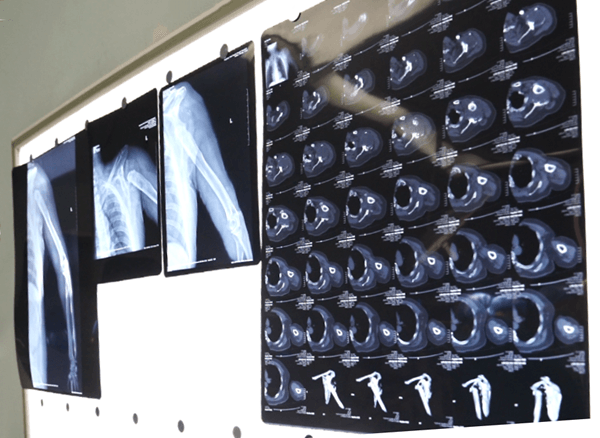

△Preoperative CT images of the patient

After Mr. Lan was hospitalized, he performed X-ray and CT examinations and found that due to the loss of the humeral head of the patient’s left arm, the structure of the left scapular labrum was destroyed and lost. the tear of the humerus and scapula caused significant bone loss, and the contracture of the muscles and ligaments around the joint, using traditional treatment techniques, cannot completely solve the patient’s problem. In order to research and formulate the best treatment plan, Zhang Haosha reported Mr. Lan’s situation to Wang Zhigang. Wang Zhigang has specialized in the diagnosis and treatment of joint diseases for more than 30 years and has extremely rich treatment experience. He is a well-known expert in the field of joint surgery both inside and outside Xinjiang. After fully understanding Mr. Lan’s condition, he thought and thought again and again, and decided to rely on 3D printing technology to perform reverse shoulder arthroplasty with a shoulder prosthesis personalized for the patient, which can not only restore shoulder stability. shoulder joint, but also rebuild the function of the shoulder joint and improve the quality of life of patients.

△Skeleton model made by 3D printing

Wang Zhigang’s team used Mr. Lan’s healthy right shoulder joint as a reference and relied on 3D printing technology to print a skeletal model that perfectly matched the shoulder joint. Mr. Lan’s left shoulder. After deliberation and repeated testing of the model, they customized the titanium inverted shoulder. prosthesis in particular glenoid prosthesis. In order to ensure the surgical effect, the team of attending doctors Wang Zhigang and Zhang Haoshaqiang repeatedly measured and inferred the surgical steps on the PACS imaging system before operation, and tested repeatedly to obtain a perfect match.

△Titanium artificial reverse shoulder joint prosthesis with glenoid prosthesis

On February 10, 2023, Wang Zhigang’s team operated on Mr. Lan. During the operation, the surgical team overcame many difficulties. “We have innovated in the surgical approach.” Wang Zhigang explained that in the past, the anterior approach was mainly chosen for shoulder arthroplasty. Due to the peculiarity of the patient’s disease, the posterior approach was necessary, but the proximal humerus and shoulder were. exposed by the expansion of the posterior surface. The glenoid part is very difficult. “The patient has old injuries to the shoulder joint, severe muscular and ligamentous scar adhesions, severe local anatomical variations, severe adhesions and deformities of blood vessels and nerves, and excessive bleeding.” is that by controlling the duration of the operation that the risk of infection can be reduced and complications minimized. “

Although the shoulder joint was measured and the prosthesis was polished and tried on several times before the operation, it still could not fit perfectly with the remaining bone tissue during the operation. Wang Zhigang made a quick decision and selected internal fixation screws of appropriate length through precise measurements during the operation. the operation. The operation lasted 4 hours and was successful. The length and range of motion of the shoulder joint on both sides were satisfactory. On the second day after the operation, Mr. Lan excitedly told the doctor, “Now I can finally sleep peacefully.” Subsequently, Zhang Haoshaqiang’s nursing staff and the rehabilitation department worked together to formulate a shoulder joint activity rehabilitation plan for Mr. Lan. After 14 days, Mr. Lan’s injury healed well and the pain in his shoulder joint almost disappeared. It was capable of lifting up to 60 degrees and removing over 50 degrees on its own. At a later stage, Mr. Lan will need to undergo appropriate rehabilitation training for at least 3-6 months to completely restore the structure and length of the shoulder joint.

“Reverse shoulder replacement with a posterior custom shoulder prosthesis is difficult and risky. Fortunately, the operation was very successful, which is rare in the country.” Wang Zhigang said the department will innovate 3D printing technology in the future. empower orthopedics, continuously promote orthopedic surgeries to be more precise and convenient, and provide high-quality medical services to people of all ethnic groups in Xinjiang.

Source: 3D Printing Network

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.