2023Year1moon4Today, according to Mohou.com, multinational oil and gas company Shell announced its latest R&D product using3DPrinted template that can be used to repair leaks.

△Shell WAAM 3D Print a leak repair clip. Photo via Shell。

This component is designed to repair pipelines affected by defects or corrosion, ensuring a continuous supply of oil and gas and the safe operation of facilities. Shell said that through wire-arc additive manufacturing (WAAM) 3D ModelPrinting technology can produce it quickly and efficiently, making customization of fixtures easier and less expensive.

3DPrinting device passes high voltage test

As there are only a limited number of companies specializing in manufacturing pressure vessels, Shell said it could take five days to manufacture a simple leak repair pliers, whereas more than four weeks would be necessary to produce more complex parts. This is an issue that merits attention given the complexity of some pipeline systems and the environmental and supply impacts of leaks caused by damaged pipelines.

To meet this need for customized repair solutions that can be deployed quickly, as well as mechanical integrity that ensures continued safe operation, Shell targets3DPrinting technology. Compared to casting or forging, the company says the technology “has advantages” because it can produce nearly net-shaped parts with minimal waste and without the need for custom tooling. To bring this idea to life, Shell chose to work withTEAM Inc.AndVallourecCollaborate to design and test a fully proof-of-concept repair device WAAM 3D Print production. The team also developed technical specifications and an inspection test plan for initial prototype parts to meet quality requirements for use in medium pressure steam systems.

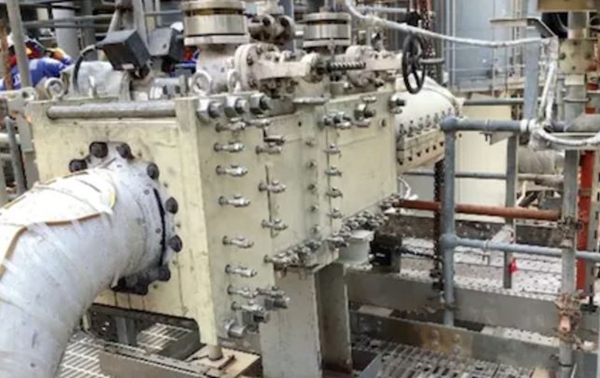

△Example of complex pipe fixing configuration. Photo courtesy of Shell.

During testing, the device successfully passed the 142.4 barThe burst test carried out under (more than five times the expected design pressure) meets the conditions for “field application”. Shell is currently working to create a database of all its inspection and qualification test results to facilitate the criticality classification of parts (and their CND Require). In the future, the company also aims to create a library of qualified configurations to reduce qualification requirements for the production of future similar products.

In a statement released alongside the project results, Shell said:“Create information about 3D The business of printing many sets of spare parts data is resource intensive. By collaborating with interested end users with similar needs, we gain more knowledge faster.WAAM Standardization of technical processes, particularly in terms of quality control, is crucial to shorten delivery times and reduce costs. Shell believes the energy sector is adopting3DA huge step forward for printing could come from this standardization across the industry. “

△Prototype of leak repair device installed on the Shell site. Photo courtesy of Shell.

Oil and gas additive manufacturing is gaining momentum

As a leading multinational oil and gas company, Shell is3DThe continued interest in printing bodes well for the future of this technology in the energy sector. The company has partnered withGE additivecooperative development3D Printed oxygen-hydrogen micromixer,Poly Productsfor reverse engineering and 3D Print spare parts for offshore drilling platforms, andMetal Forge 3D Modelused for3D Print the heat exchanger tubes.

2021Year7moon,AML3DShe was also revealed to have provided services to ExxonMobil.3DPrinted one8One ton pressure vessel demonstrator. The initial order value is only 190,000 dollars, but the project is a showcase of oil and gas deposits3DOpportunities with the potential of printing technology. Elsewhere,Hunting automatonby acquisition Cumberland Additive 27% actions to enter the industry. When the deal was announced late last year, it marked Hunting Enter 3D printing sector and offers it opportunities to enter the aerospace, defense and oil and gas markets.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.