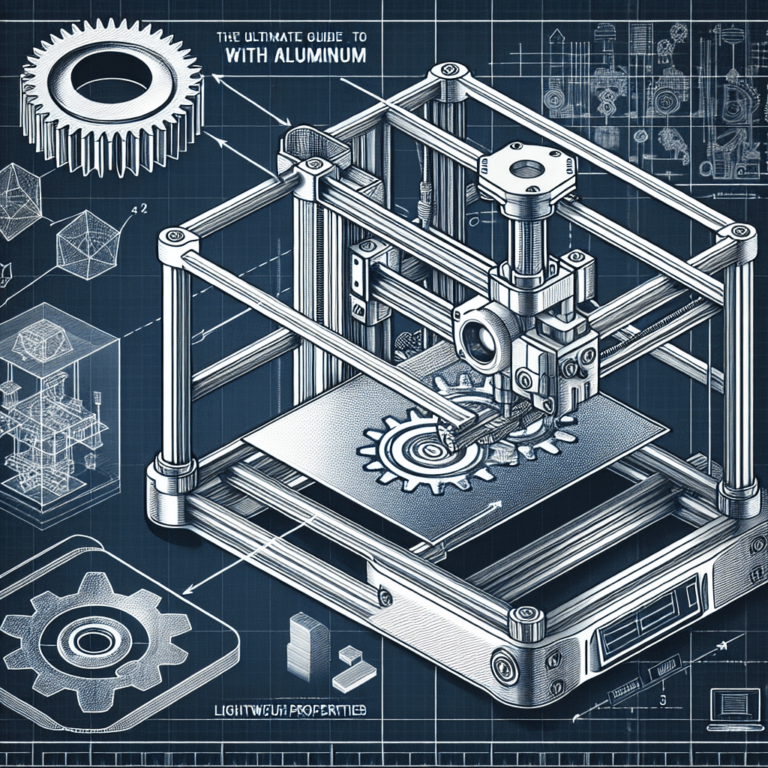

Understanding 3D Printing Aluminum

3D printing, also known as additive manufacturing, has revolutionized how we conceptualize, design, and produce parts. Among the materials that have gained traction in the 3D printing arena, aluminum stands out due to its unique properties, lightweight nature, and versatility. In this comprehensive guide, we will explore the different aspects of 3D printing with aluminum, including the processes, benefits, challenges, applications, and future trends.

The 3D Printing Process for Aluminum

3D printing aluminum generally involves powder bed fusion processes, primarily Selective Laser Melting (SLM) and Electron Beam Melting (EBM). Both methods employ different energy sources to fuse aluminum powder layer by layer.

Selective Laser Melting (SLM)

SLM utilizes a high-powered laser to selectively melt aluminum powder on a build platform. The process involves the following steps:

- Preparation of the Aluminum Powder: The aluminum powder is spread evenly across the platform.

- Laser Melting: The laser scans and melts the powder according to the digital 3D model, creating a solidified layer once the powder cools.

- Layering: After one layer is complete, the build platform descends, and a new layer of powder is spread on top. The process is repeated until the final part is built.

Electron Beam Melting (EBM)

EBM employs an electron beam to melt aluminum powder, suitable for creating parts with high thermal conductivity. The procedural steps are quite similar to SLM but differ primarily in the energy source. Key features include:

- Vacuum Chamber: EBM is performed in a vacuum to minimize oxidation.

- Higher Build Temperatures: EBM can operate at elevated temperatures, which can be beneficial for some aluminum alloys.

- Speed: EBM generally allows for a faster build time due to its higher energy input.

Benefits of 3D Printing with Aluminum

Integrating aluminum into your 3D printing projects offers several advantages that can enhance manufacturing processes and product design.

Lightweight and Strong

Aluminum is incredibly lightweight while also maintaining high strength-to-weight ratios. This property makes it ideal for industries such as aerospace and automotive where weight savings directly translate to improved fuel efficiency and performance.

Corrosion Resistance

Aluminum exhibits natural corrosion resistance due to the formation of a protective oxide layer. This feature is particularly beneficial in applications requiring durability in harsh environments, making it a prime choice for marine applications.

Design Flexibility

3D printing allows for the creation of complex geometries that would be impossible or cost-prohibitive with traditional manufacturing methods. This design flexibility enables engineers and designers to produce intricate lattice structures, heat exchangers, and custom components tailored to specific applications.

Reduced Waste

Traditional manufacturing techniques often generate significant amounts of scrap material. In contrast, 3D printing is an additive process, meaning that material is added layer by layer with minimal waste generated, making it more environmentally friendly.

Rapid Prototyping

3D printing enables rapid prototyping, allowing engineers to quickly design, test, and iterate components. With aluminum, companies can produce functional prototypes that closely resemble the final product, accelerating the product development cycle.

Challenges of 3D Printing with Aluminum

Despite its many benefits, 3D printing aluminum is not without its challenges. Understanding these potential obstacles can help mitigate their impact.

Material Properties Variation

Different aluminum alloys have distinct properties such as strength, ductility, and thermal conductivity. Finding the right alloy for specific applications can require extensive testing and may complicate the material selection process.

Warping and Shrinkage

Aluminum is susceptible to warping and shrinkage during the cooling phase of the printing process. Careful consideration must be given to part design and build environment to minimize these issues and ensure dimensional accuracy.

Cost of Equipment

High-quality metal 3D printers capable of processing aluminum can be prohibitively expensive. This cost can make it challenging for small businesses or startups to adopt 3D printing technology, although leasing options or service bureau sourcing can mitigate this challenge.

Post-Processing Requirements

Aluminum parts typically require significant post-processing due to rough surface finishes and dimensional inaccuracies. Post-processing methods, such as CNC machining or polishing, can add time and costs to the overall production process.

Applications of Aluminum 3D Printing

Aluminum 3D printing is widespread across various industries, demonstrating its versatility and applicability.

Aerospace Industry

The aerospace sector utilizes aluminum’s lightweight and strength characteristics for components such as brackets, housings, and support structures. 3D printing technologies help produce complex geometries that minimize weight while maintaining structural integrity.

Automotive Manufacturing

In automotive manufacturing, aluminum is used for prototyping engine components, transmission mounts, and other structural elements. Its ability to reduce weight and enhance performance makes it a preferred choice for both traditional automotive design and the increasing number of electric vehicles.

Medical Devices

In the medical field, aluminum parts are used for surgical instruments and implants. Its biocompatibility, coupled with the ability to customize designs for specific patients, makes aluminum 3D printing a promising avenue in medical technology.

Consumer Products

3D printing aluminum has found a place in consumer product design, offering manufacturers the opportunity to create innovative designs, lightweight structures, and custom parts that can enhance user experience and product performance.

Tooling and Fixtures

Many manufacturers are turning to aluminum 3D printing for tooling and fixtures. Custom jigs and fixtures can be designed quickly and inexpensively, helping to improve efficiency in production environments.

Future Trends in Aluminum 3D Printing

The landscape of aluminum 3D printing is evolving rapidly, fueled by advancements in technology and material science.

Advanced Alloys Development

Research and development efforts are geared towards creating new aluminum alloys that offer improved properties tailored for additive manufacturing. These alloys will expand the application range of aluminum 3D printing.

Integration of AI and Machine Learning

AI and machine learning technologies are beginning to play a significant role in optimizing the 3D printing process. These technologies can predict and mitigate defects, enhancing the quality and reliability of 3D printed aluminum parts.

Sustainability Initiatives

The push for sustainability in manufacturing is prompting more companies to explore aluminum 3D printing as an environmentally friendly alternative. The emphasis on reducing waste and improving energy efficiency may well transform the 3D printing landscape.

Automation and Industry 4.0

With the integration of Industry 4.0 practices, the incorporation of automation in 3D printing will increase efficiency and productivity. This trend could lead to faster turnaround times, cost reductions, and an overall enhancement in manufacturing capabilities.

Conclusion

3D printing aluminum is at the forefront of modern manufacturing technology, presenting innovative solutions to traditional challenges across various industries. While it comes with its unique set of challenges, the benefits of using aluminum in 3D printing—including lightweight strength, design versatility, and reduced waste—position it as a powerful tool in the manufacturing arsenal. As technology continues to advance, the future of aluminum 3D printing looks promising, with new applications and improvements on the horizon. Embracing these innovations opens up a world of possibilities for engineers, designers, and manufacturers alike, ushering in an era of enhanced creativity and efficiency in production.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.