Bone abnormalities, whether congenital or caused by accident, require treatment tailored to their root cause. Treatment options include those developed by researchers at Beihang University, Renji Hospital, Shanghai Jiao Tong University, Tsinghua University and Beijing.3D printed zinc scaffolds show promise for treating large bone defects. The project is supported by the Chinese company Bright Laser Technology (BLT), which supplies the necessary 3D printers and systems.

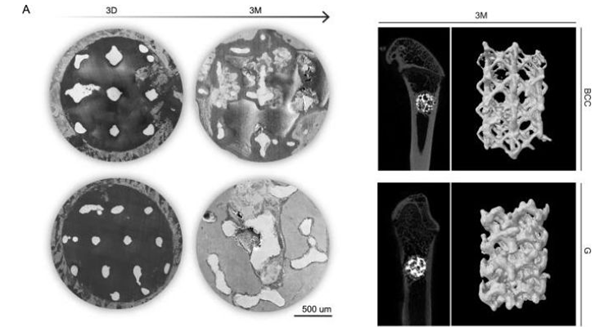

ThesePorous 3D printed zinc structures represent a new approach to repairing bone defects through bone regeneration. However, the rapid degradation of zinc, leading to potential toxicity, poses a major obstacle so far. To overcome this problem, efforts have been made to optimize the alloy composition, surface structure, and pore geometry of the scaffold.

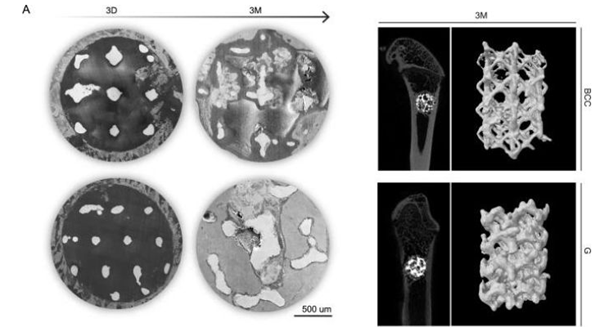

Three days and three months laterDegradation behavior of 3D printed zinc scaffolds in rat femur (Photo credit: Li, S., Yang, H., Qu, X., et al. Multi-scale structural design of porous zinc-based scaffolds 3D printed biodegradable products for immunology regulating osteogenesis Nat Commun 15, 3131, 2024).

Over the past three years, researchers have developedA new biodegradable zinc alloy (Zn-Li) for 3D printing of these structures. Zinc-lithium alloys have an excellent balance between strength, plasticity and corrosion resistance. The frames are produced using BLT’s DMLS system, which allows for precise designs and complex structures.

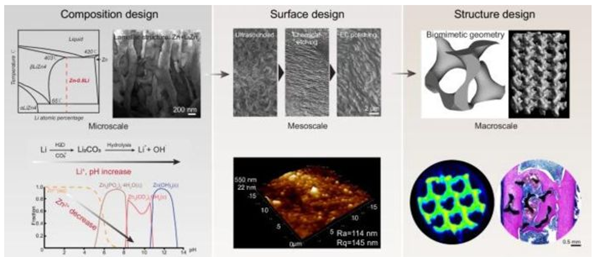

After 3D printing, various surface treatments such as ultrasonic treatment, acid etching and electropolishing are used to optimize surface roughness and promote cell interaction. These processes make it possible to obtain precise microstructures of the surface, thus improving adhesion and cell proliferation, essential elements for effective bone regeneration.

Design of 3D printed zinc-based porous biodegradable scaffolds (Image source: Li, S., Yang, H., Qu, Scale architecture design. Nat Commun 15, 3131, 2024)

Additionally, specific surface structures facilitate interactions with macrophages, the white blood cells necessary for immune responses to potentially harmful substances. This interaction may enhance immune responses, thereby promoting bone regeneration. Also,The 3D printed zinc scaffold degrades in a controlled manner in the body. This ability is essential to create an optimal environment for implant regeneration and integration.

3D printed scaffolds represent an advancement over traditional implants by promoting more efficient bone regeneration. The structural and chemical properties of these scaffolds stimulate the formation of new bone. 3D printing of zinc-lithium scaffolds allows precise control of the structure and porosity of the implant, essential elements for successful bone regeneration. For more information, click here.

After sonication, acid etching and electrochemical polishingSurface morphology and properties of Zn-0.8Li scaffolds (Image source: Li, S., Yang, H., Qu, X. et al. Multi-scale structural design of zinc-based biodegradable materials printed in 3D) for immunomodulation. . Nat Commun 15, 3131, 2024. )

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.