It’s no secret that one of the main advantages of 3D printing is its customization capabilities. 3D printing is booming in consumer goods, medical and other fields due to its unique advantages. The same goes for 3D printed shoes, with many brands, including Adidas and Reebok, using additive manufacturing.

Today, Mohou.com will introduce you to a new 3D printing shoe company – Zellerfeld. It is reported that Zellerfeld has launched a public beta version of its 3D printing shoe platform, which users can purchase for themselves.

Zellerfeld

Zellerfeld’s core philosophy is to provide users with 3D printed shoes. 3D printed shoes are fully recyclable and the entire manufacturing process is more sustainable. By scanning with a mobile phone, the most suitable shoes can be customized according to the foot shape of different users. The shoes produced are made from 3D mesh material, which can be machine washed. The material is made from sustainable materials through automated production (no overseas factories required). It is these features that make Zellerfeld the favorite of many major shoe brands. For example, Danish outerwear brand Rains collaborated with Zellerfeld to launch the “Puffer Boot” at Paris Fashion Week.

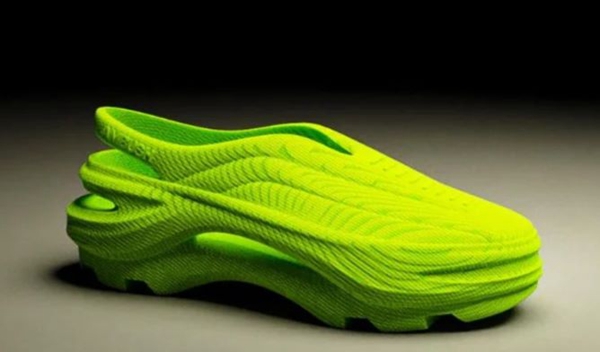

△Shoes available for purchase on Zellerfeld’s 3D printed shoe platform

Eliminating the need for overseas factories and improving sustainability will help solve two of the clothing and footwear industry’s biggest problems. For example, workers are underpaid and have unsafe working conditions, which often leads to tragedies such as the 2013 Rana Plaza factory collapse, which killed 1,124 workers and was the failure deadliest structural accident in modern human history and one of the deadliest garment factory disasters in history. A. By moving to automated and localized production, 3D printing can help eliminate this problem.

Durability is also an issue. Even though “sustainable” fashion is gradually entering the public consciousness, the fact is that it is difficult to find completely sustainable brands, and the fashion industry remains the second most polluting industry in the world after oil. According to TheRoundup, 87% of materials used to make clothing end up in landfills. 3D printing can play a key role in this, and Zellerfeld is specifically committed to ensuring that its products are not only made from sustainable materials and free from harmful textiles, rubber and leather, but that they are also recyclable, as customers can return their old shoes when they buy new ones. those.

△Zellerfeld has launched a number of 3D printed shoes through cooperation with other shoe brands, including this shoe in cooperation with AMBUSH

Public Open Beta Platform for 3D Printed Shoes

Previously, Zellerfeld conducted a closed beta program, only providing access to selected tests, to gather valuable feedback on its 3D printed shoes. Thanks to a new $15 million funding round led by Founders Fund, they are now opening this beta program to the public, making 3D printed shoes accessible to everyone. Zellerfeld noted that customers will be able to choose one of 15 exclusive designs, including those from major brands such as Heron Preston, KidSuper and KITTY, which is a significant step forward for the footwear industry. All 15 designs feature the company’s 3D printing technology, which includes custom, print-to-order, single-material, and fully recyclable designs that require no sewing or gluing components.

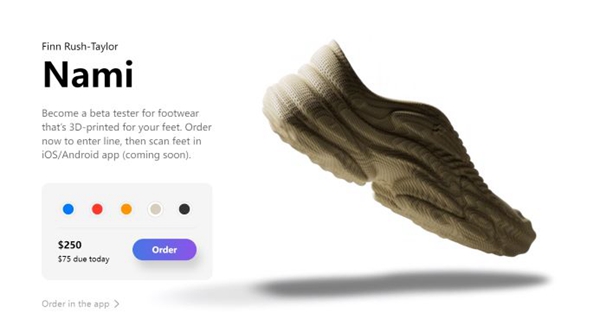

Take for example a new 3D printed sneaker released by Finn Rush-Taylor Studio and Zellerfeld in 2022. This shoe is called “Nami”. It is now only available on the official Zellerfeld website for $250. favorite color and make your purchase. Nami shoes are made from fully recyclable materials and require no sewing or gluing, and have a slip-on silhouette and a simple, stylish solid color palette.

Cornelius Schmitt, co-founder and CEO of Zellerfield, concluded: “We are delighted to partner with Founders Fund, who will help us revolutionize the footwear industry. This funding will allow us to continue innovating with our proprietary technology and expand our platform to reach more designers and consumers around the world, and we are particularly proud that our technology is now supported by the Founders Fund. is a partner we greatly admire because it often plays a key role in funding core technology projects that are reshaping our society today and in the future.

In its report on “3D Printed Shoes 2020-2030 Footwear Industry 3D Printing Market Potential Analysis”, SmarTech Analysis noted that the footwear industry revenue is expected to reach 4, 2 billion dollars by 2025. We can say that 3D printing is making a splash in the shoe industry. The benefit of 3D printing is to increase the speed and agility of product development as well as the freedom of the design process, which provides more customization possibilities and new ideas for shoe brands.

Source: Internet

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.