Since20century60Since the first space flights in the 1990s, humans have dreamed not only of visiting planets in space, but also of inhabiting them. Although living on the Moon or Mars may seem like science fiction, it is actually a topic that some organizations are actively working on,3DPrinting is perhaps one of the keys to its success. And now it could be one step closer to feasibility.

△Conceptual habitat for an outpost on Mars

2022Year10moon29Now, according to Mohou.com, researchers at the University of Florida have managed to create3DPrint bricks that can be used to build the base of Artemis Base Camp, made of Lunar Stormstone and Salt Water.

This is certainly not the first time that efforts have been made to3DThe printing press is used to build housing in space. In fact, some projects are already underway in this direction. This includesRewireThe company is conducting tests aboard the International Space Station to determine whether lunar regolith, or deposits of soil and rock from the lunar surface, could be used to create habitable environments, which NASA is currently working with.AIProduced in cooperation with Space Factory3DPrinting lunar habitats and Washington State University on Mars3DPrinted research. However, until now this has been relatively hypothetical. This is one of the first projects demonstrating that Thunderstone bricks can withstand the extreme environment of space.

△Lunar slates are composed of loose rocks, dust and materials found on the lunar surface (Image source: NASA)

3DPrinted Moonstone Bricks Can Withstand Extreme Environments

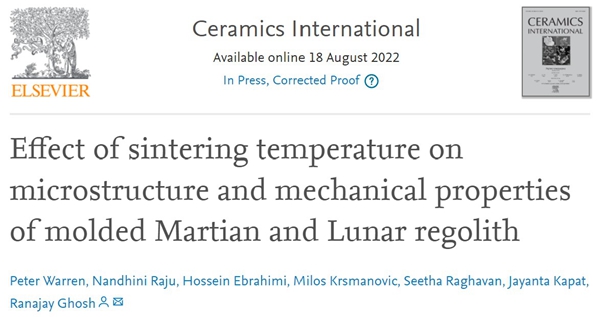

3DMoon Brick Printing Project byUCFfrom the Department of Technology and Aeronautical EngineeringRanajay ChasmThe researcher is an associate professor and the relevant results are presented in the title “Effect of sintering temperature on the microstructure and mechanical properties of cast Martian and lunar regolith/The article “The effect of sintering temperature on the microstructure and mechanical properties of cast Martian and lunar regolith” was published in the latest issue of “International Ceramics”. The lead author is a research assistant.Peter Warrenbut co-authors includeNandhini Raju, Hossein Ebrahimi, Milos Krsmanovicand professor of aerospace engineeringSeetha RaghavanAndJayanta Kapa. They tried to find out if they could use them3DLunar Thunderstone bricks printed to build a stationary Artemis Base Camp on the Moon.

Links to related articles:

To make the bricks, the team used a binder jetting method in which the binder is composed of salt water andUCFMade from exo rock powder from the exo rock laboratory. Binder jetting is a perfect technology because it is particularly suitable for ceramic-like materials that are difficult to melt with a laser.GhoulsIt was further stated that this gives it great potential for alien manufacturing based on the Lightning Stone. Even though the initial green parts were relatively fragile, after treatment up to1200After being fired at high temperatures of 100 degrees Celsius, the bricks are strong enough to perform their function.

△Associate Professor, School of Mechanical and Aerospace Engineering, University of CaliforniaRanajay Ghoshand graduate research assistantPierre WarrenThese are cylindrical bricks made from simulations of lunar and Martian storms and salt water (Image source:UCF)

And the results are undoubtedly promising. The researchers found that the resulting cylindrical bricks were able to withstand2.5Billions of times the pressure of Earth’s atmosphere. This suggests that binder jetting could be used in the future for building space materials and structures. More importantly, it shows that structures beyond this world will be able to be built using resources found in space. By charting this path, future missions will be able to reduce the valuable space and weight constraints associated with transporting construction materials, making habitability much more likely.

GhoshThe summary says:“The research contributes to the ongoing debate within the space exploration community about striking a balance between in situ use of extraterrestrial resources and transportation of materials from Earth. The more we develop the technology to harness the abundance of Lightning Stone, the better equipped we will be to establish and expand future base camps on the Moon, Mars, and other planets.“

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.