Glass is an extraordinary material because, as long as it is not contaminated, it can be recycled indefinitely without altering its properties. This is one of the reasons why additive manufacturing is interesting. In addition, compared with traditional glass casting,3D printing methods allow for greater design flexibility and reduced costs. Given these characteristics, MIT engineers wanted to test the feasibility of using glass in additive manufacturing to produce structural construction elements. So they developed 3D printed glass masonry elements that stack and fit together like Lego bricks.

The research was led by MIT engineersDirected by Daniel Massimino, Ethan Townsend, Charlotte Folinus, Michael Stern and Kaitlyn Becker. Together, they created strong, multi-layered soda-lime glass bricks, each shaped like a figure eight. Each brick has two round pegs, just like Lego bricks, allowing them to be positioned and rearranged infinitely, resulting in tremendous compositional diversity and a sustainable life cycle. If not assembled, the bricks can be melted down for reprinting.

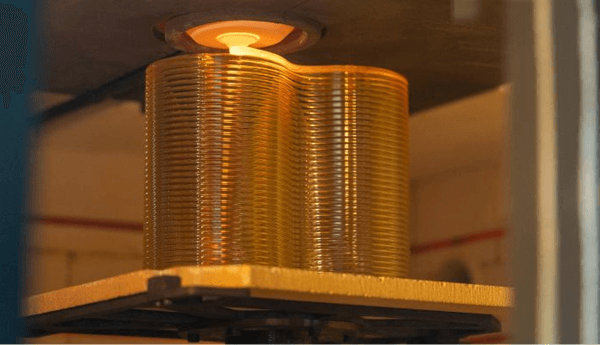

Glass block printing process (photo source:Ethan Townsend)

In an article published by MIT News, Daniel“Thanks to the figure-eight shape, we can constrain the bricks when they are put together to form walls with a certain curvature,” explains Massimino. This working method is part of the concept of circular architecture, where building materials are reused. should be carried out wherever possible to reduce carbon emissions associated with the overall construction of the building. The durability of the glass blocks was a key factor in the study.

3D printed glass as a construction material

MIT engineers used a device calledGlass 3D Printer 3 (G3DP3), a custom glass 3D printer provided by MIT spinoff company Evenline. The machine uses an oven to melt crushed glass bottles into a printable form, which is then layered. The machine can print up to a maximum volume of 32.5 x 32.5 x 38 cm, enabling the production of full-size masonry units.

The team printed three types of building blocks– fully hollow, molded printed and fully printed – and found that “hollow masonry elements offer more direct implementation possibilities, while fully printed elements have the potential to provide a method of manufacturing transparent architectural elements and rounded.

They tested the strength of the blocks using an industrial hydraulic press and found that the strongest blocks could withstand the same pressure as concrete blocks. The strongest are those that have a separate locking device at the bottom and are made from different materials.“Glass is a complex material to process,” Becker explains in the same MIT News article. “At this stage, interlocking elements made of different materials are the most promising. » According to the article, the researchers plan to print more interlocking glass elements.

Engineers build glass wall on MIT campus to showcase theirThe potential of 3D printed bricks. In the future, they plan to use these blocks to build larger, more complex structures and believe they could be used on both exterior and interior walls.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.