3D printing is developing rapidly in various fields such as medicine, automobiles, aerospace… but it has also found its place in our files. In fact, the food industry is benefiting from this technology, with the 3D printed food market expected to reach $472 million in 2022, according to global market estimates. The possibilities offered by this technology are vast, ranging from desserts to meat products to fruits and vegetables. The growing number of 3D food printers are changing the way we produce and consume food, with the ability to create dishes with different textures and materials. Far from science fiction, several companies such as La Pâtisserie Numérique, Steakholder Foods, 3D Systems and Natural Machines offer solutions for the design of these printed food products, hinting at a new culinary era.

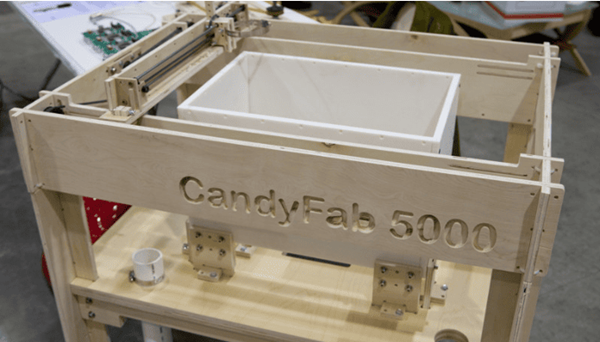

However,Early results from 3D food printing have been modest. The pieces obtained are made from sugar paste and often leave something to be desired. But the development of technology, mainly the deposition of molten material, allowed the process to be perfected, making chocolate, candy and even real meals possible. Initially, most of the machines used were modified FDM desktop 3D printers; we are now seeing 3D food printers specifically designed to produce delicious and delicate dishes. But what is the future of 3D food printing? Could it revolutionize the way we eat?

3D printed chocolate candies. (Photo credit: Sugar Lab)

The beginning of 3D food printing

3D food printing is a relatively new innovation. In 2006, a team from Cornell University in the United States developed the first 3D food printer called Fab@Home. The machine can print chocolate, cookie dough and even cheese, allowing it to create artistic shapes from these ingredients. Early applications of the technology focus on easy-to-use materials. For example, CandyFab, also founded in 2006, designed a printer capable of producing complex structures from sugar. Appreciated for its ability to melt and solidify easily, chocolate was one of the first ingredients used, allowing it to create complex shapes.

Now let’s go to space:NASA has been interested in 3D food printing since 2006, studying its potential to provide food for astronauts. One of the goals is to improve meals during long-duration space missions. In 2013, the agency launched the Advanced Foods Initiative to develop food solutions better suited to these conditions. It partnered with startup BeeHex to develop the Chef3D printer, capable of creating 3D printed pizzas which are then simply cooked. This technology could make space meals more varied and enjoyable, which would be a significant advantage for long-distance missions, as current meals are often considered monotonous and unappetizing.

why turn3D food printing?

Food is currently under great pressure and new trends have emerged in recent years. When it comes to food, many people tend to dismiss technology. withIn speaking with Lynette Kucsma, CEO and co-founder of Natural Machines, she told us that when we told her about 3D food printers, she was reluctant at first. She felt like she was eating processed foods. But as she dug deeper, she realized the goal was completely different: “If you eat something in a supermarket or grocery store, it’s the same. The food is also fed into a machine and put into a mold. printer, you can choose the foods you use.

The co-founder of Natural Machines also highlighted the innovative nature of 3D food printing: new flavors and shapes can be created, which can have an impact on the health of the end consumer. This was shared by Jonathan Blutinger, researcher at the Creatives Machines Lab, who explained that the 3D food printer is comparable to the classic FDM 3D printer: it is today capable of manufacturing geometrically complex parts, such as than food machines. We then obtain very original dishes which retain their original flavor.

3D printed broccoli (Image source: Gastrology)

3D printed foods can also provide solutions to various challenges, not just the dishes themselves. One solution is to address food insecurity, which currently affects 258 million people in 58 countries and territories and continues to grow. To answer this question, two Qatari students, Mohammed Fadhel Annan and Lujain Al-Mansoori, developed a 3D printer capable of mass producing fruits and vegetables from cells grown in the laboratory. The innovation is based on a 3D printing process using ultraviolet light called “mask stereolithography”.

3D food printing can also provide solutions to other problems. For example, many people suffer from dysphagia, difficulty swallowing, which makes eating very complicated. The Dutch startup Gastronology’s mission is to solve this problem by developing 3D printed foods that are delicious and adapted to the needs of these patients, making meals more enjoyable. Gastronomy uses 3D food printers and specialized industrial machines to reproduce food products. Founder Peter Nieuwkerk said: “The result: 3D printed broccoli that looks like broccoli, smells like broccoli, tastes like broccoli, but can be eaten with a spoon by people with dysphagia. »

3D food printing: Have fun while protecting your health and the environment

3D food printers could also be a great way to personalize dishes and adapt them to very specific diets that have emerged in recent years. We think of gluten and lactose intolerances, but also of the whole vegan movement. 3D printing will become a new way of cooking, respectful of each person’s specific situation. We can also connect machines to sensors to monitor calorie counts or sugar, fat or protein levels.

The popularity of meat products has declined in recent years, largely due to growing awareness of animal suffering and negative environmental impacts. Faced with these challenges, many people turn to a vegetarian or vegan diet. However, due toWith 3D printing, another solution is emerging. Several companies, including Steakholder Foods, are developing plant-based alternatives for a variety of products. Their goal: to create foods with a lower impact on the environment. Whether shrimp, fish fillets, eels or meat, these companies are developing “inks” composed of proteins and other ingredients that faithfully replicate the properties of the original food. These inks are then used in a 3D printer which deposits them layer by layer to form the desired structure.

What is the future of 3D food printing?

The future of 3D food printing is bright and there are many opportunities for innovation in the industry. One of the major expected advances is nutritional personalization. In the near future, it will be possible to adapt meals to the specific nutritional needs of each individual, whether based on age, level of physical activity or medical requirements such as diabetes or food intolerances. Technological advances will make it possible to more faithfully reproduce the texture and taste of traditional foods. Many companies are seeking alternatives to meat and seafood that increasingly mimic the texture of animal proteins.

The technology is not ready to be present in all the kitchens of tomorrow; consumers are not ready to accept such a change. But it’s only a matter of time. Additionally, upon closer inspection, you will find that the same problem occurs with microwave ovens, which are now integrated into most kitchens.

Photo credit:Digital Pastry

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.