Tool wear is a common problem in mechanical processing, which directly affects processing quality, production efficiency and manufacturing costs. Understanding the causes of tool wear and their solutions can effectively extend the tool life and improve the processing effect. Here are the main causes of tool wear and the corresponding solutions:

1. Main causes of tool wear

1. Causes of excessive cutting speed: Excessive cutting speed leads to increased friction and cutting heat between the tool and workpiece, thereby accelerating tool wear. Solution: Depending on the material type and tool characteristics, reduce the cutting speed reasonably to avoid tool wear due to overheating.

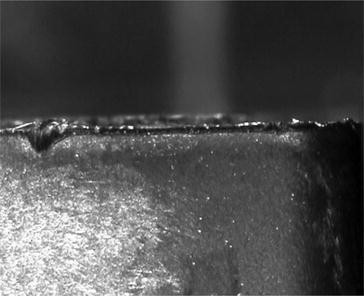

2. Reasons for excessive feed: Excessive feed will increase the cutting force, resulting in increased mechanical stress on the tool cutting edge, and the tool is prone to chipping or wear. Solution: Appropriately reduce the feed amount to ensure a smooth cutting process and reduce the load on the tool.

3. Reasons for excessive cutting depth: Excessive cutting depth significantly increases the cutting force supported by the tool, resulting in increased tool wear. Solution: Optimize the cutting depth and adopt a step-by-step cutting method to gradually reach the required depth and reduce the load on the tool.

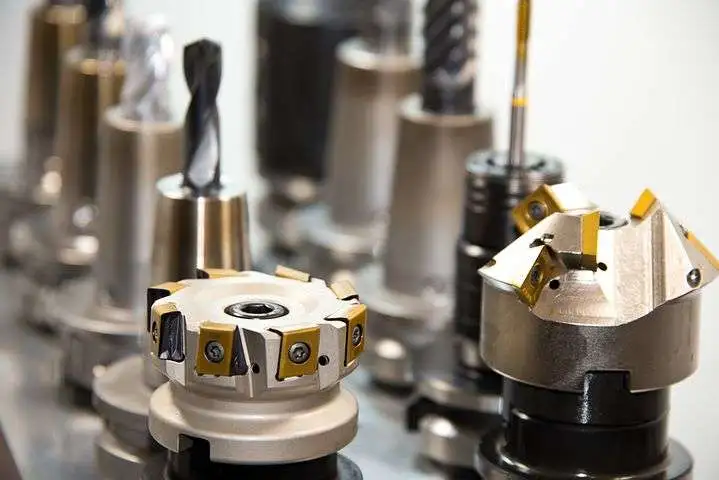

4. The reason why the tool material is not suitable: the tool material is incorrectly selected and cannot meet the hardness, toughness and other requirements of the processing material, resulting in leads to accelerated wear of the tool. Solution: Choose appropriate tool materials according to processing materials, such as carbide, ceramic, diamond coatings, etc., to improve wear resistance and service life.

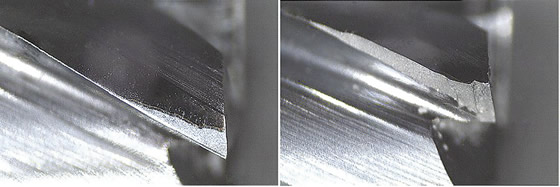

5. Reasons for unreasonable geometric angles of the tool: The rake angle, clearance angle and tool tip angle are set unreasonably, resulting in an increase in cutting force or heat buildup, which intensifies tool wear. Solution: Optimize the geometric angle of the tool according to specific processing requirements to ensure reasonable distribution of cutting forces and reduce heat accumulation.

6. Cause of insufficient tool cooling: Insufficient cooling during the cutting process causes the tool to become too hot and accelerates tool wear. Solution: Use sufficient coolant or lubricant to ensure the tool is completely cooled during the cutting process.

7. Reasons for improper selection of cutting fluid: The type or ratio of cutting fluid is inappropriate, which cannot provide sufficient cooling and lubrication effects and accelerate tool wear. Solution: Choose the appropriate type of cutting fluid for the material and tool being processed, and ensure that the concentration and flow rate of the cutting fluid are appropriate.

8. The reason why the workpiece material is too hard: The workpiece material has high hardness, which makes the tool bear greater wear force during the cutting process. Solution: Use tool materials with better wear resistance or reduce the hardness of the workpiece material through heat treatment and other methods.

9. The reason why the tool is not clamped firmly: The tool is not clamped on the machine tool or is not clamped firmly, causing the tool to friction during the process of cuts and worsens wear. Solution: Ensure the tool is securely mounted on the machine tool, using appropriate clamping devices and clamping force.

10. Causes of machine tool vibration: Machine tool vibration or instability will cause uneven force on the tool during the cutting process, thereby accelerating wear. Solution: Improve the rigidity of the machine tool, reduce vibration sources and ensure stable processing.

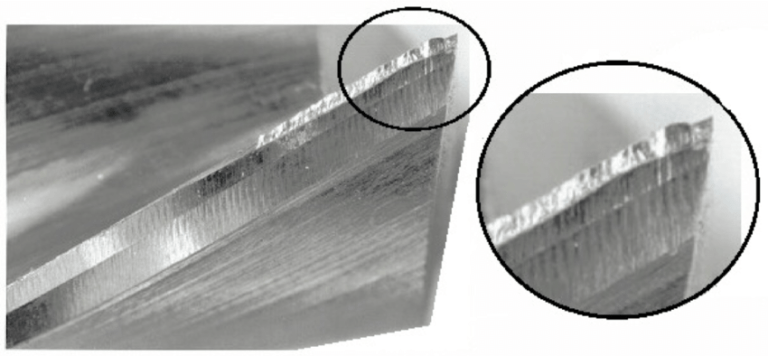

11. Reason for poor chip evacuation in the cutting zone: Chips accumulate in the cutting zone, forcing the tool to recut the processed chips and increasing tool wear. Solution: Use an efficient chip removal device or remove chips regularly to ensure a clean cutting area.

12. Reasons for poor processing environment: The temperature, humidity or other factors in the processing environment are unstable, which affects the performance and wear of the tool. Solution: Improve the processing environment, control temperature and humidity, and reduce the negative impact of the environment on the tool.

2. Solutions

1. Optimize the cutting parameters and reduce the cutting speed: according to the characteristics of the processing material and the tool, reasonably reduce the cutting speed, reduce heat generation, and delay tool wear. Reduce the feed amount: Reduce the feed amount appropriately to ensure stable cutting force and reduce tool wear.

2. Select the appropriate tool material. Select the tool according to the workpiece material: such as carbide, ceramic or diamond tools, adapt to materials of different hardness and toughness, and improve the wear resistance of the tool.

3. Adjust the geometric angle of the tool to optimize the cutting angle and clearance angle of the tool: adjust the geometric angle of the tool according to the cutting conditions to make the cutting force and reasonable cutting heat distribution and reduce tool wear.

4. Improve the cooling and lubrication system and use sufficient coolant: ensure adequate coolant supply, lower the cutting zone temperature and reduce thermal wear of the tool. Choose the right lubricant: Choose the right lubricant according to the cutting material to improve the lubricating effect of the cutting process.

5. Maintain and replace tools regularly. Check the condition of tools regularly: discover tool wear problems in time, repair or replace them, and maintain the cutting effect. Replace badly worn tools: When the wear of the tool reaches a certain level, it should be replaced in time to avoid a decline in the processing quality.

6. Improve the clamping of the machine tool and workpiece to ensure that the tool is firmly installed: use high-quality tool clamping devices to ensure the stability of the tool on the machine tool. Improve machine tool rigidity: reduce machine tool vibration, improve the stability of the machining process, and reduce abnormal tool wear.

7. Use an effective chip removal system to ensure rapid chip discharge: Use an effective chip removal system to prevent chips from accumulating in the cutting area and prevent the tool from recutting the chips .

8. Improve the processing environment and control the temperature and humidity of the processing environment: reduce the impact of environmental factors on cutting tools and ensure that cutting tools operate under optimal conditions.

Tool wear is inevitable, but by understanding its causes and taking effective solutions, tool life can be significantly extended and processing quality and production efficiency can be improved. Reasonable tool selection, optimization of cutting parameters, improvement of cooling and lubrication systems, and regular tool maintenance are key strategies to reduce tool wear.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.