Today, Mohou.com will focus on introducing10The family continues to develop with3DThe start-ups in the printing sector, they are all present 2019 Premiering later this year. By exploiting the potential of technologies like additive manufacturing, these startups are2022achieved astonishing results and collected a total of almost 8000 million dollars in venture capital funding (although 38% Sank towards GE business).

1、Matta:clever 3D printer

MattaFounded in 2022 year, relying on the University of Cambridge. Under continuous research and development by a team of engineers and scientists, the company files for a patent capable of autonomously learning artificial intelligence technology and algorithms to correct problems of different parts, materials and systems.3DPrinting error. Currently, the team is working on 3D The printer is developing a universal operating system that leverages the latest machine learning research and cloud services to provide insights for additive manufacturing. The researchers strive to apply their learning algorithms end-to-end, from design to manufacturing, to create “highly consistent and highly complex products.” Algorithms that detect and correct various errors in real time are extremely valuable and can be easily added to new or existing machines. at present,Matta The founder ofNatural communications、Additive manufacturingAndAdvanced intelligent systemsSeveral articles have been published in journals.

△Machine learning algorithms are used to detect and correct errors in real time 3D Example image of printer nozzle

2、Additive insurance:Quality control

When companies like Volkswagen and Boeing must ensure their 3D When the printed pieces were flawless, they turned to researchers at Monash University.Additive insurance. This Australian startup is developing a laser powder bed fusion method (LPBF) Marketing of a new in situ process monitoring tool for metal additive manufacturing. The name of this technology isAMiRISwhich allows manufacturers to ensure the structural integrity of components during manufacturing and to correct anomalies when they occur. More importantly, this new AM Process monitoring methods open new avenues for automatic fault detection, prediction and prevention. Based on patent-pending technology,AMiRIS A suite of optical sensors are combined to collect micron-level details and provide rich process insights through machine learning. Thanks to the latest round of financing,Additive insurance Already high 590 million Australian dollars (400 million), plans to build one at its headquarters in Melbourne, Australia AM Center of excellence in quality assurance and international team expansion.

△Use Additive insurance machine learning algorithms and software built 3D picturepicture

3、Vitro3D:volume 3D Print

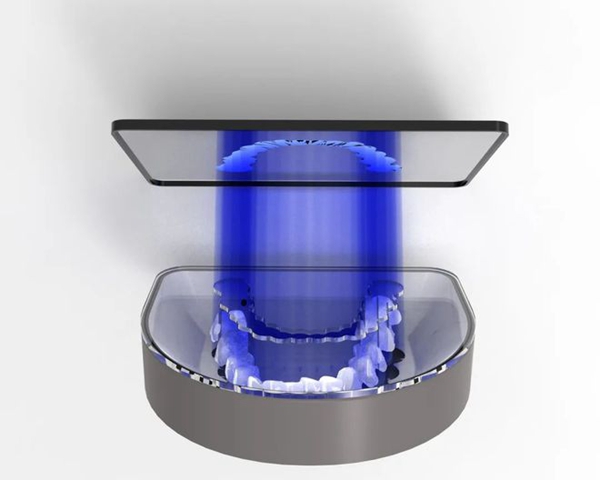

Leverage the University of Colorado and the Colorado Life Sciences Incubator ProgramVitro3D established in 2020 years, mainly developed for production and use 3D New three-dimensional dental devices and scaffolds for cell culture and tissue engineering 3D printing method,Vitro3DRaised in latest round of seed funding 130 million dollars.

Vitro3Dvolume3DPrint better than what already exists 3D Fast printing technology 100 times, capable of providing complex services 3D The object prototype printer. Additionally, use Vitro3D Volumetric cartridge printers will help solve one of the biggest problems in the dental market by allowing dentists to create custom aligners in-house.Vitro3D We hope to serve a wider range of fields beyond dentistry in the future, providing immediate patient care.

4. Stronger metals: Wired solution

Stronger metals Simplifying large format metal with its patented welding alloy 3D The printing process. as3D elementAs a spin-off, the materials manufacturer offers new powder raw materials to meet the needs of aerospace customers and robotic welding manufacturers.Stronger metals Headquartered in Louisville, Colorado, leverages patented technology to introduce high-performance metal alloys, initially focused on arc and laser-directed energy deposition applications.(DED) Aircraft grade aluminum welding wire. The company recently completed aAM VenturesLeading investment 200 Ten thousand US dollars in seed funding,AM Ventures It’s the industry 3D Leading venture capital firm in the printing industry (New York2023 One of the network sponsors of the Additive Manufacturing Strategy event), since 2021Since its creation, it has increased 370 million dollars.

△Stronger metals Director of Operations Brett Pardikes。

5、Systemic bio:Organ models of the future

biotechnology startupsSystemic bioHAS 2022 year from 3D systems has separated and will use 3D systems Bioprinting technology uses biomaterials and human cells to create precise models of vascularized organs. The Houston, Texas-based startup acquired from its parent company 1500 Ten thousand US dollars in seed funding to prove the effectiveness of its technology and business model,Systemic bio The objective is to achieve annual turnover within five years1billion dollars. Startup says it will target its proprietary organ-on-a-chip platform for drug discovery and development h-VIOS Bioprint of very complex, custom-designed vascularized tissues. In addition to providing organ-on-a-chip test samples, pharmaceutical companies may also seek to retain Systemic bio to provide contract research services and procure custom designed products h-VIOS to carry out their research and testing.

△Contains two vascularized hydrogels infused h-VIOS2

6、GE(GE): Trends Division

GE(NYSE:GE) decided to split into smaller listed companies:GE Aerospace、GE HealthAndGE Vernova。GE additive Founded in 2016 years, currently established in many European countries, and is committed to creating AM Center to accelerate the use of this technology.GE Health From 2023 Year 1 moon 5 Trading began on Nasdaq on GEHC. at the same time,GE Vernova intends to locate its global headquarters in Massachusetts. with the greatest potential for recovery GE Aerospace Agreements were signed as an independent company, value was signed with the Ministry of Defense 2.03 Billion-dollar contract for new jet engine technology.

7、Heterofusion:Multi-material printing

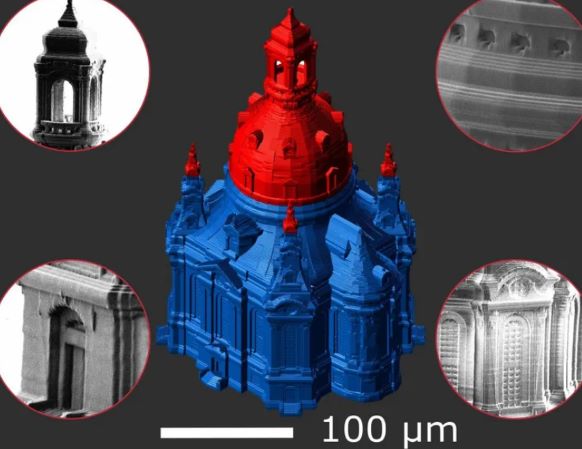

Like the Technical University of Dresden in Germany(TU Dresden) spin-off company,Heterofusionworking on his micro-scale multi-material project 3D Printing technology. This startup is developing the next generation of high-resolution automated systems 3D printing systems, even on systems as low as 100 Multi-material printing can also be carried out in extremely small structures, on the order of nanometers. According to TU Dresden, the technology provides manufacturing technology for a variety of new application areas, particularly in the areas of micro-optics, microfluidics and photonics packaging, but also in the area of tissue engineering, thus becoming high precision printing systems. industrial applications.

△ Model of the Dresden Frauenkirche with microscopic image of printed details.

8、Syenta: Transformation of electronic manufacturing

Also in the multi-materials sector, Australia 3D starting the printerSyentaRecently bred in seed round 370 million Australian dollars (250 million) to accelerate its multi-material development 3D Printer production allows customers to manufacture highly complex and powerful electronic products such as semiconductors, batteries and sensors. like the Australian National University(ANU) spin-off company,Syenta Our mission is to democratize electronic manufacturing. Since 2020 For years,Syenta(Recently renamed Spark3D) developed a unique electrochemical process 3D Printers to produce polymer, semiconductor or metallic structures.

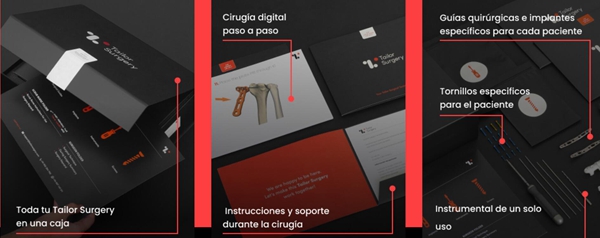

9. Tailor-made surgery:Personalized surgery

Customized surgeryFounded in 2021 years, fromTauli Park Institute of Research and Innovation(I3PT) Separate and targeted trauma3D Print. This startup offers complete solutions for plastic surgery 3D Digital Surgical Services and offers fully customized patient-specific instruments, fully customized implants and all ancillary instruments provided by surgeons for each patient, dedicated to collaborating with surgeons and engineers to personalize surgical procedures using ‘a guide plate made of biocompatible materials. exist Customized surgery Before becoming a startup,I3PT A team of 3D laboratories must respond Tauli Park clinical and research needs. Since then,3D Printing has been used exponentially to diagnose and treat patients and has achieved approximately 500 surgery. In the future, the company will also focus on the design and manufacturing of personalized implants.

10、OPT industry

Industry OPTHAS 2019 Born at MIT, it specializes in the design and mass production of products requiring extremely high micron precision. This startup3D printing technology RAMPIt is a roll-to-roll based digital lithography technology currently used in the medical and consumer goods industries. Some of the newer commercial products includeInstaSwaba high-performance nasal swab;Lumofilpersonalized mascara applicators for different eyelash contours;PolyBrusha replaceable brush pad used to line vibrating conveyor surfaces. Of the 2022 Year 8 In March, the company raised more than 2000 million dollars in funding and launched a 14,000 square feet of manufacturing facilities, which helps increase R&D, manufacturing and service capabilities.

Source: Antarctic Bear

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.