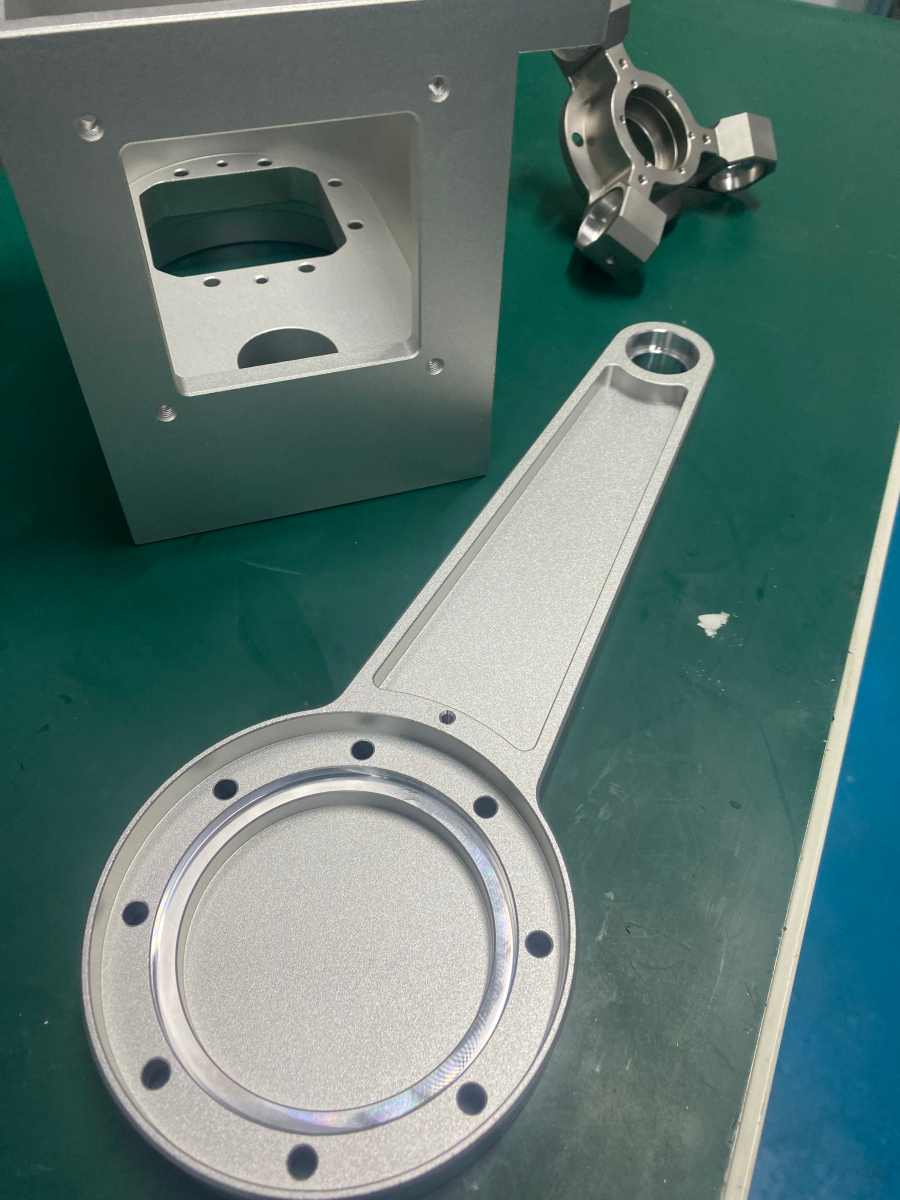

数控机床加工厂高效编排的5大秘诀:从钜亮五金看精密制造的流程优化

在精密零件制造领域,“效率”与”质量”始终是客户最关注的两大核心指标。对于数控机床加工厂而言,如何通过科学编排生产流程,在保证加工精度的同时缩短交付周期、降低成本,是决定企业竞争力的关键。东莞市钜亮五金科技有限公司(以下简称“钜亮五金”)凭借十余年行业深耕,总结出一套高效编排的实战方法论,本文将结合其技术实践与行业经验,解析数控加工厂提升效率的5大核心策略。

一、 工艺路径规划:从“经验驱动”到“数据驱动”的优化

痛点:传统加工厂依赖工程师个人经验设计工艺路径,易导致工序冗余、装夹次数过多,进而引发效率低下与误差累积。

钜亮实践:

数字化工艺仿真:通过PowerMill、UG等CAM软件,对复杂零件的加工路径进行虚拟仿真,提前识别干涉风险、优化刀具轨迹,减少试切次数。例如,在加工新能源汽车电控壳体时,利用五轴联动仿真将装夹次数从4次降至2次,单件加工时间缩短30%。

标准化工艺库:建立覆盖铝、不锈钢、钛合金等常用材料的工艺参数数据库,针对不同精度要求(如±0.01mm与±0.001mm)预设加工策略,新项目可直接调用,避免重复试错。

DFM(可制造性分析)前置:在客户图纸阶段介入,通过结构优化建议减少加工难度。例如,针对某医疗植入物零件的薄壁结构,提出增加加强筋的方案,既提升了强度又降低了加工变形风险。

行业对比:

传统工厂:依赖人工排产,工艺设计耗时占比达20%-30%。

钜亮模式:通过数字化工具将工艺设计时间压缩至5%以内,且一次加工合格率提升至98%以上。

二、 设备资源协同:多轴联动与柔性生产的平衡

痛点:加工厂常面临“大设备忙不过来、小设备闲置”的资源错配问题,尤其是五轴机床等高端设备利用率不足,导致成本攀升。

钜亮实践:

设备分级管理:根据零件复杂度与精度要求,将设备划分为“五轴专区”“四轴高效区”“三轴基础区”,实现“复杂件用五轴、简单件用三轴”的精准匹配。例如,在某航空发动机叶片项目中,五轴机床负责曲面精加工,三轴机床完成粗加工,整体效率提升40%。

柔性产线设计:通过车铣复合中心、走芯机等设备集成,实现“一次装夹完成多工序加工”。例如,某轴类零件在车铣复合机上完成车削、铣槽、钻孔等全部操作,装夹时间减少80%,同轴度误差控制在±0.002mm以内。

动态排产系统:引入MES(制造执行系统),实时监控设备状态(如刀具寿命、主轴负载),自动调整生产顺序,避免因设备故障导致的停机。钜亮五金通过该系统将设备综合效率(OEE)从65%提升至82%。

行业对比:

普通工厂:五轴机床利用率常低于50%,单件成本高。

钜亮模式:通过设备协同与柔性生产,五轴机床利用率达75%以上,复杂件成本降低25%。

三、 供应链垂直整合:从“外协依赖”到“全链可控”

痛点:外协加工(如热处理、表面处理)常因沟通不畅导致质量波动、交期延误,甚至引发责任推诿。

钜亮实践:

内部工艺链闭环:自建压铸、钣金、3D打印等辅助产线,覆盖从毛坯到成品的90%以上工序。例如,某汽车零部件项目原需外协热处理,钜亮通过内部真空淬火炉完成,交期从15天缩短至5天,且硬度均匀性提升15%。

供应商分级管理:对必须外协的工序(如特殊电镀),建立“白名单供应商库”,要求其通过IATF 16949或ISO 13485认证,并定期审计。例如,某医疗零件的阳极氧化工序,仅与通过ISO 13485认证的供应商合作,确保生物相容性达标。

数字化协同平台:通过ERP系统与供应商共享生产计划,实现“JIT(准时制)配送”。例如,某大型框架结构项目,通过系统自动触发原材料采购,库存周转率提升30%。

行业对比:

传统模式:外协占比常超40%,质量风险高。

钜亮模式:外协占比控制在15%以内,且100%可追溯。

四、 质量管控前置:从“事后检验”到“过程预防”

痛点:传统质检依赖终检,发现缺陷时已产生大量废品,返工成本高昂。

钜亮实践:

SPC(统计过程控制)应用:在关键工序(如五轴加工、精密磨削)设置在线检测点,实时采集尺寸数据并生成控制图。例如,某航空零件的孔径加工,通过SPC监控将CPK值从1.0提升至1.67,不良率从2%降至0.03%。

防错装置(Poka-Yoke):在工装夹具中设计定位销、传感器等,防止装夹错误或刀具磨损导致的加工偏差。例如,某医疗植入物零件的夹具中集成压力传感器,当夹紧力不足时自动停机,避免零件松动。

全流程追溯系统:通过二维码或RFID标签,记录每一件零件的加工设备、操作人员、检测数据等信息。例如,某汽车客户要求提供“单件追溯报告”,钜亮通过系统快速生成,满足IATF 16949要求。

行业对比:

普通工厂:终检发现缺陷的比例常超10%,返工成本占销售额的5%-8%。

钜亮模式:过程缺陷率控制在0.5%以内,返工成本不足1%。

五、 人才与组织:从“单兵作战”到“团队协同”

痛点:精密加工依赖高技能操作工,但传统“师傅带徒弟”模式培养周期长,且经验难以复制。

钜亮实践:

技能矩阵管理:将操作工技能划分为“基础操作”“编程调试”“工艺优化”等层级,通过内部认证体系激励员工提升。例如,某五轴机床操作工通过“工艺优化”认证后,可独立设计加工方案,效率提升20%。

跨部门项目组:针对复杂项目(如人形机器人关节),组建由工艺工程师、编程员、质检员组成的专项团队,通过每日站会同步进度。例如,某机器人项目通过团队协同,将开发周期从3个月压缩至6周。

知识管理系统:将典型案例、工艺参数、问题解决方案等录入内部数据库,新员工可通过关键词检索快速获取经验。例如,某新入职工程师通过查询“钛合金加工变形控制”案例,一周内掌握关键技巧。

行业对比:

传统工厂:员工技能单一,跨项目协作效率低。

钜亮模式:通过组织优化,项目交付周期平均缩短25%。

结论:高效编排的核心是“系统化思维”

数控机床加工厂的高效编排,并非单一环节的优化,而是工艺、设备、供应链、质量、人才五大维度的系统集成。钜亮五金的实践表明,通过数字化工具、柔性生产、垂直整合、过程预防与团队协同,可在保证±0.001mm级精度的同时,将交付周期缩短40%、成本降低25%。对于客户而言,选择一家具备系统化编排能力的供应商,意味着更低的创新风险、更高的项目成功率。

常见问题解答(FAQ)

Q1:钜亮五金能加工哪些材料?

A:钜亮可加工铝、不锈钢、钛合金、高温合金、模具钢等金属材料,以及ABS、PC、尼龙等工程塑料,覆盖从软质到硬质、从常规到特种的广泛需求。

Q2:五轴加工与三轴加工的核心区别是什么?

A:三轴加工仅能沿X/y/z三个直线方向移动,适合平面或简单曲面;五轴加工增加A/C两个旋转轴,可实现复杂空间曲面的一次性成型,减少装夹次数,精度更高。

Q3:如何确保加工零件的精度?

A:钜亮通过三重保障:

设备端:使用德玛、北京精雕等高端五轴机床,定位精度达±0.001mm;

工艺端:采用SPC统计过程控制,实时监控关键尺寸;

检测端:配备三坐标测量仪、激光扫描仪等设备,100%全检高精度零件。

Q4:小批量订单能否接?

A:可以。钜亮拥有127台设备,涵盖从快速原型到批量生产的全能力,小批量订单(如10-100件)可通过柔性产线快速交付,成本优于传统大厂。

Q5:如何保护客户的设计数据安全?

A:钜亮通过ISO/IEC 27001信息安全管理体系认证,采取以下措施:

内部网络与外部互联网物理隔离;

设计文件加密存储,仅限授权人员访问;

与员工签订保密协议,违规者追究法律责任。