数控加工中心硬度揭秘:从材料到工艺的深度解析

在精密零件制造领域,数控加工中心的“硬度”是一个多维度的概念——它不仅关乎加工材料的物理性能,更涉及设备本身的刚性、刀具的耐磨性以及工艺控制的稳定性。对于研发企业、硬件创业者及采购工程师而言,理解这些“硬度”维度,是选择可靠供应商、确保项目成功的关键。东莞市钜亮五金科技有限公司(以下简称“钜亮五金”),凭借十余年深耕精密制造的经验,为您揭开数控加工中心“硬度”的真相。

一、材料硬度:精密零件的物理基石

材料硬度是数控加工中最基础的“硬度”维度,直接影响零件的耐磨性、强度及加工可行性。

1. 常见加工材料的硬度范围

铝合金:硬度范围约20-150 HB(布氏硬度),因其轻量化、易加工特性,广泛应用于汽车、航空航天领域。但低硬度也意味着易划伤,需通过表面处理(如阳极氧化)提升硬度。

不锈钢:硬度通常在150-300 HB之间,耐腐蚀性强,但加工时易产生加工硬化,对刀具和工艺要求较高。

钛合金:硬度可达300-400 HB,比强度高,常用于医疗植入物和高端航空零件。但其导热性差,加工时易烧刀,需采用专用刀具和冷却工艺。

模具钢:硬度可超过50 HRC(洛氏硬度),用于制造高耐磨模具。其高硬度对加工设备的刚性提出极高要求。

2. 材料硬度对加工的影响

刀具磨损:高硬度材料会加速刀具磨损,需选择更耐磨的涂层刀具(如TiAlN涂层)或缩短换刀周期。

加工参数:硬度越高,切削速度需降低,进给量需减小,以避免刀具崩刃或零件变形。

表面质量:高硬度材料加工后表面粗糙度可能更高,需增加精加工工序(如抛光)或采用更精密的加工设备。

钜亮五金实践:针对高硬度材料(如钛合金、模具钢),钜亮采用德国进口超硬刀具,结合五轴联动加工技术,确保在低切削力下实现高精度成型,同时通过内部检测实验室的硬度测试设备,严格验证材料性能是否符合客户要求。

二、设备刚性:抵御加工力的“隐形硬度”

设备刚性是数控加工中心的核心“硬度”指标,它决定了设备在加工过程中抵抗变形的能力,直接影响加工精度和表面质量。

1. 刚性不足的典型表现

让刀现象:加工高硬度材料或深腔零件时,刀具因受力产生弹性变形,导致实际切削量小于理论值,零件尺寸偏小。

振动:刚性不足的设备在高速切削时易产生振动,在零件表面留下振纹,降低表面质量。

精度衰减:长期加工高硬度材料会加速设备磨损,导致精度逐渐下降。

2. 提升设备刚性的关键因素

床身结构:采用整体铸造床身或大理石床身,比焊接床身具有更高的抗变形能力。

导轨与丝杠:高精度滚珠导轨和滚珠丝杠能减少运动摩擦,提升传动刚性。

主轴设计:大功率、高转速的主轴(如电主轴)能提供更稳定的切削力,减少振动。

钜亮五金优势:钜亮引进的德玛、北京精雕等品牌五轴CNC加工中心,均采用高刚性床身设计,配备高精度滚珠导轨和电主轴,最大加工尺寸达4000mm,可稳定实现±0.001mm的极限精度,即使加工高硬度材料也能保持长期精度稳定。

三、工艺控制:从“硬加工”到“软控制”的硬度管理

工艺控制是数控加工中“软性”但至关重要的“硬度”维度,它通过优化加工参数、刀具路径和检测流程,确保即使在高硬度材料加工中也能实现稳定输出。

1. 关键工艺控制点

切削参数优化:根据材料硬度、刀具类型和设备刚性,调整切削速度、进给量和切削深度。例如,加工钛合金时,切削速度通常需控制在30-60 m/min,进给量0.05-0.2 mm/r。

刀具路径规划:采用顺铣(Down Milling)而非逆铣(Up Milling),可减少切削力,降低刀具磨损和振动。

冷却与润滑:高硬度材料加工时需使用高压冷却液,及时带走热量并减少切屑粘刀。

2. 检测与反馈机制

在线检测:通过探头实时监测零件尺寸,及时调整加工参数,避免批量报废。

SPC统计过程控制:对关键尺寸进行全程监控,分析数据波动,提前发现潜在问题。

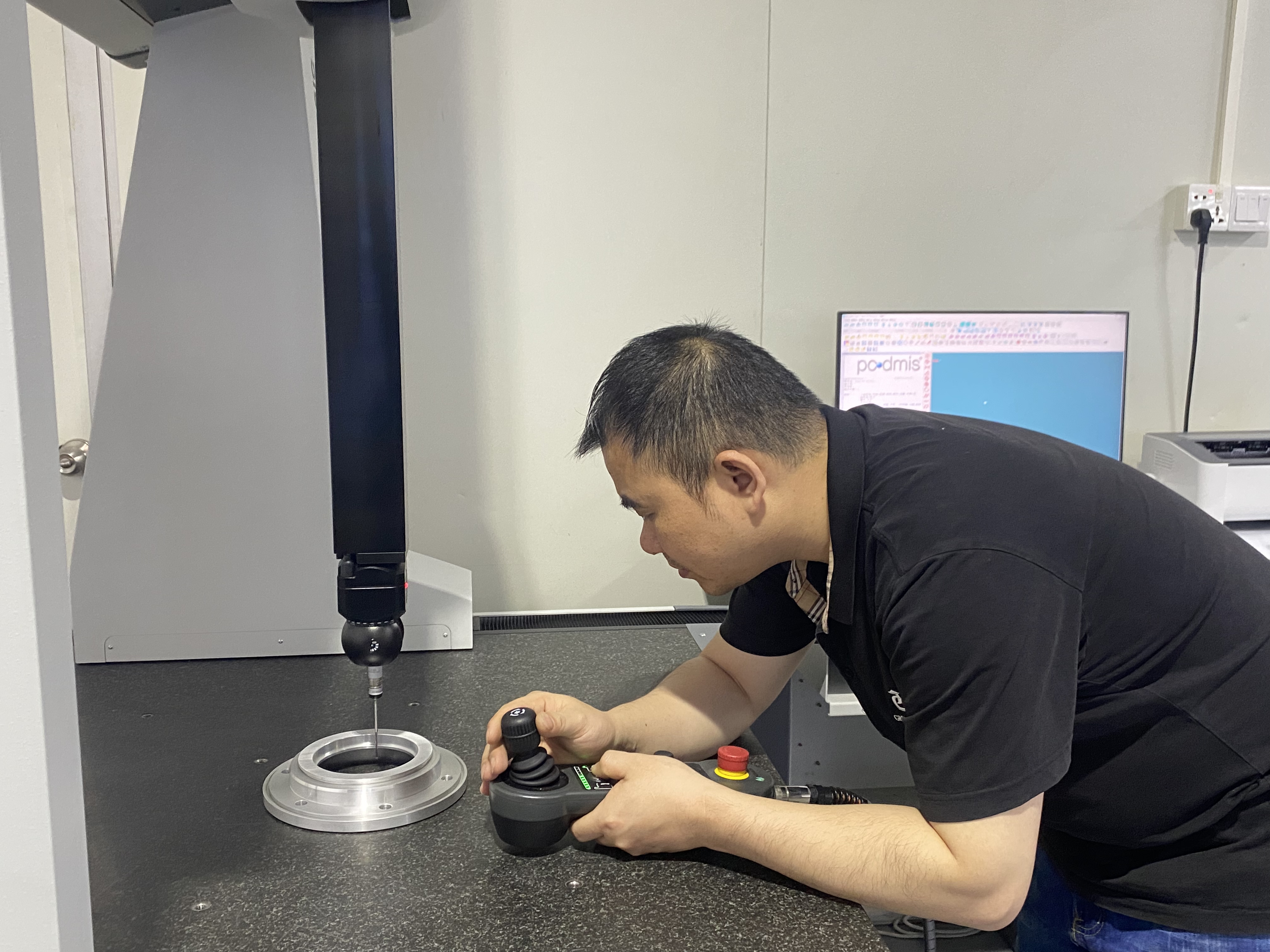

三坐标测量:加工完成后使用高精度三坐标测量机(CMM)验证零件精度,确保符合图纸要求。

钜亮五金实践:钜亮严格执行IATF 16949汽车行业质量管理体系,对每一批零件的关键尺寸进行SPC监控,并通过内部检测实验室的硬度测试、金相分析等手段,确保材料性能和加工质量双达标。

四、行业痛点与钜亮解决方案:硬度管理的现实挑战

痛点1:高硬度材料加工精度失控

问题:部分供应商宣称能加工高硬度材料,但实际生产中因设备刚性不足或工艺不稳定,导致零件尺寸超差或表面质量不达标。

钜亮方案:

设备保障:五轴CNC加工中心采用高刚性床身和电主轴,可稳定加工硬度达50 HRC的模具钢。

工艺验证:针对每一类高硬度材料,建立标准化的加工参数库,并通过试切验证工艺可行性。

检测闭环:加工后使用三坐标测量机进行全尺寸检测,确保精度符合±0.001mm要求。

痛点2:供应链碎片化导致质量责任真空

问题:高硬度零件加工可能涉及热处理、表面处理等多个环节,若供应商缺乏全工艺链能力,易出现质量扯皮。

钜亮方案:

一站式服务:覆盖精密CNC加工、热处理、表面处理(如电镀、喷砂)等全工艺链,客户无需对接多家供应商。

全流程追溯:通过ERP系统记录每一道工序的操作人员、设备参数和检测数据,实现质量问题的快速定位与追溯。

痛点3:认证资质与实际能力断层

问题:部分供应商展示ISO 9001证书,但未获得行业专属认证(如IATF 16949、ISO 13485),无法满足汽车、医疗等高端领域的要求。

钜亮方案:

多认证体系:不仅通过ISO 9001质量管理体系,更获得IATF 16949(汽车)、ISO 13485(医疗)、ISO/IEC 27001(信息安全)等顶级认证,确保能力与客户需求精准匹配。

认证范围明确:每项认证均明确覆盖“汽车行业五金零件设计与生产”“医疗五金件研发制造”等具体范围,避免“一证通用”的风险。

结论:选择“硬实力”供应商,规避精密制造风险

在数控加工领域,“硬度”不仅是材料的物理属性,更是设备、工艺和管理的综合体现。钜亮五金凭借高端设备集群、全工艺链整合能力、国际权威认证体系以及深度工程协同服务,为客户提供了从材料硬度管理到工艺控制的全方位解决方案。无论是新能源汽车电控壳体、医疗植入级零件,还是航空航天复杂结构件,钜亮都能以“硬实力”确保项目成功,助力客户在高端制造领域赢得竞争优势。

常见问题解答(FAQ)

Q1:钜亮五金能加工哪些高硬度材料?

A:钜亮可加工从常规铝合金、不锈钢到高硬度钛合金(硬度达400 HB)、模具钢(硬度超50 HRC)等广泛材料,并针对不同材料特性优化工艺参数。

Q2:高硬度材料加工的交期是否更长?

A:高硬度材料加工需更谨慎的工艺控制和刀具管理,因此单件加工时间可能更长。但钜亮通过五轴联动加工技术和柔性生产能力,可显著缩短从样件到量产的周期,紧急项目可优先排产。

Q3:如何确保加工后的零件硬度符合要求?

A:钜亮内部检测实验室配备硬度测试仪、金相显微镜等设备,可对原材料和成品进行硬度检测和微观组织分析,确保材料性能和热处理效果符合客户规格。

Q4:与钜亮合作是否需要承担更高的成本?

A:钜亮通过规模化生产、工艺优化和全工艺链整合,在保证质量的前提下控制成本。对于高硬度材料加工,虽然单件成本可能略高于普通材料,但钜亮的一站式服务可帮助客户节省多头管理成本和潜在质量损失。

Q5:钜亮五金是否支持小批量高硬度零件加工?

A:是的。钜亮拥有从单件快速打样到大规模量产的全周期服务能力,最小起订量可低至1件,特别适合研发阶段的小批量高硬度零件加工需求。