Custom CNC Milling Services

Achieve Perfect Tolerances and Fast Turnarounds!

- Over 60 Certified Materials

- ±0.005mm Tight Tolerance

- Custom Finishes

- Lead times from 7 days

- Customer data security

Our CNC Milling Capabilities

Are you searching for a dependable supplier of CNC-milled parts?

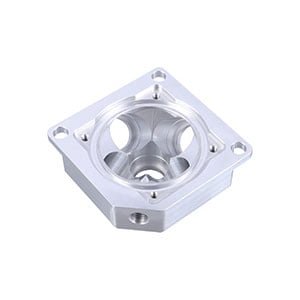

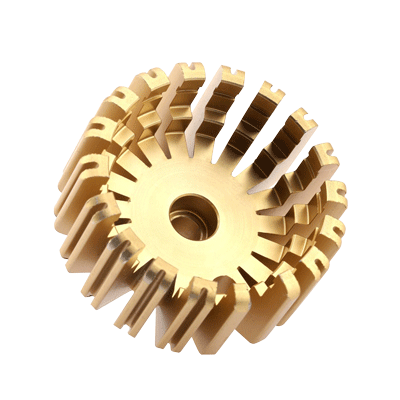

Gallery Of Our

CNC Milling Parts

Get Your Parts Into Production Today!

How Great Light Works

We've boiled down the innovation process to just three simple, effective steps.

Get Instant Quote

Simply upload your design to our email, and within 12 hours, get an instant quote and a free design analysis for your prototypes and production parts. Easy-peasy!

Start Production

Once you have approved the quote and design, we will start production on your CNC prototype or CNC machined parts products.

Receive Your Custom Parts

CNC machined parts or products will be produced within a few days. We ship to you by international express. Please feel free to give us feedback to ensure that they meet your expectations.

CNC Milling Materials

CNC Metals

Aluminum is lightweight yet strong, with excellent machinability and corrosion resistance. Ideal for aerospace and automotive parts.

Alloys

Aluminum 6061, 6061-T6

Aluminum 2024

Aluminum 5052

Aluminum 5083

Aluminum 6063

Aluminum 6082

Aluminum 7075, 7075-T6

Aluminum ADC12 (A380)

Copper is known for its superior electrical conductivity and thermal properties, making it perfect for electrical components and heat exchangers.

Copper is known for its superior electrical conductivity and thermal properties, making it perfect for electrical components and heat exchangers.

Alloys

Copper C101(T2)

Copper C103(T1)

Copper C103(TU2)

Copper C110(TU0)

Beryllium Copper

Brass is durable and has a low friction coefficient, which makes it suitable for fittings, tools, and musical instruments that require precision.

Alloys

Brass C27400

Brass C28000

Brass C36000

Bronze is highly resistant to corrosion and metal fatigue, favored for bearings, bushings, and marine hardware.

Alloys

Tin Bronze

Steel is an alloy with high tensile strength and durability, commonly used in construction and automotive industries for its robustness.

Alloys

Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36

Die steel

Alloy steel

Chisel tool steel

Spring steel

High speed steel

Cold rolled steel

Bearing steel

SPCC

Stainless steel is renowned for its corrosion resistance, making it a prime choice for medical devices and food processing equipment.

Alloys

Stainless Steel SUS201

Stainless Steel SUS303

Stainless Steel SUS 304

Stainless Steel SUS316

Stainless Steel SUS316L

Stainless Steel SUS420

Stainless Steel SUS430

Stainless Steel SUS431

Stainless Steel SUS440C

Stainless Steel SUS630/17-4PH

Stainless Steel AISI 304

Magnesium is the lightest structural metal, offering high strength-to-weight ratios, perfect for automotive and aerospace applications where weight is critical.

Alloys

Magnesium Alloy AZ31B

Magnesium Alloy AZ91D

Titanium boasts the highest strength-to-density ratio among metals, highly resistant to corrosion and fatigue, ideal for aerospace, medical, and marine applications.

Alloys

Titanium Alloy TA1

Titanium Alloy TA2

Titanium Alloy TC4/Ti-6Al 4V

CNC Plastics

ABS is strong, durable, and offers good resistance to heat and impact. It’s preferred for automotive components and consumer goods.

ABS Beige(Natural)

ABS Black

ABS Black Antistatic

ABS Milky White

ABS+PC Black

ABS+PC White

Polycarbonate is extremely durable and has high impact resistance, along with excellent clarity, used for bullet-proof glass and protective gear.

PC Black

PC Transparent

PC White

PC Yellowish White

PC+GF30 Black

PMMA, or acrylic, is known for its crystal clarity and weather resistance, making it ideal for outdoor fixtures and display cases.

PMMA Black

PMMA Transparent

PMMA White

POM is strong, with a low friction surface and good dimensional stability, perfect for precision parts in mechanical applications.

Dark brown (coffee) POM 100AF

POM Black

POM Blue

POM White

Nylon is versatile, strong, and wears well against friction, commonly used for gears, bearings, and other wear-resistant surfaces.

PA(Nylon) Blue

PA6 (Nylon)+GF15 Black

PA6 (Nylon)+GF30 Black

PA66 (Nylon) Beige(Natural)

PA66 (Nylon) Black

Polyethylene is lightweight and has high resistance to impact, widely used in packaging and containers.

PE Black

PE White

PEEK is renowned for its high temperature resistance and strength, often used in aerospace and medical implant manufacturing.

PEEK Beige(Natural)

PEEK Black

Polypropylene is tough, has excellent chemical resistance, and is used for automotive parts, containers, and in packaging.

PP Black

PP White

PP+GF30 Black

HDPE is known for its high strength-to-density ratio, resistance to impacts, and is used in making bottles and corrosion-resistant piping.

HDPE Black

HDPE White

HIPS is easy to machine and offers good dimensional stability and impact resistance, suitable for prototyping and modeling.

HIPS Board White

LDPE is soft, flexible, and used in applications where heat sealing is required, such as in tubing and plastic bags.

LDPE White

CNC Milling Surface Finishes

Whether you require anodizing, plating, or painting, we ensure your parts meet both aesthetic and functional specifications.

As Machined

As Machined

Anodizing

Anodizing

Polishing

Polishing

Electroplating

Electroplating

Brushed Finish

Brushed Finish

Powder Coating

Powder Coating

FAQs For CNC Milling Services

CNC milling is a manufacturing process that involves using computer-controlled machines to remove material from a workpiece to create a desired shape or design. The milling machine uses rotating cutting tools to remove material from the workpiece to achieve the desired shape. This process is used to create a wide range of parts and products with high accuracy and precision.

CNC Milling can work with a wide range of materials including metals (such as aluminum, brass, stainless steel, titanium, and more), plastics (such as ABS, acrylic, nylon, polycarbonate, and more), and even composites (such as carbon fiber and fiberglass). Some materials may be more challenging to work with than others, and may require specialized tooling or techniques to achieve the desired results.

CNC milling provides more precise and consistent results than manual machining, and it allows for more complex geometries and features to be created.

The typical lead time for CNC milling parts at Great Light varies depending on factors such as the complexity of the part, the quantity needed, and the availability of materials. However, we always strive to provide our customers with fast turnaround times and efficient production processes. Contact us to discuss your specific project and lead time requirements.

Yes, we offer both CNC milling and CNC turning services at Great Light. Our state-of-the-art facilities include a wide range of CNC machines, including milling and turning centers, which allow us to produce high-quality parts with a quick turnaround time. Our experienced team of engineers and machinists can help you determine which service is best suited for your specific needs and requirements. Contact us today to discuss your project and learn more about our CNC milling and turning services.

Yes, CNC milling can be more cost-effective and time-efficient than other manufacturing methods, especially for larger production runs or complex parts.

Yes, CNC milling is an ideal solution for creating rapid prototypes and small production runs of custom parts. It allows for quick and accurate adjustments to be made, resulting in faster product development and time to market.

Get The Best Price

Get Your Free Quote Today!

- 100,000+ Unique parts produced

- 300+ Companies served

- 30+ Countries shipped

- 15+ Years of Experience