Description

$0.50

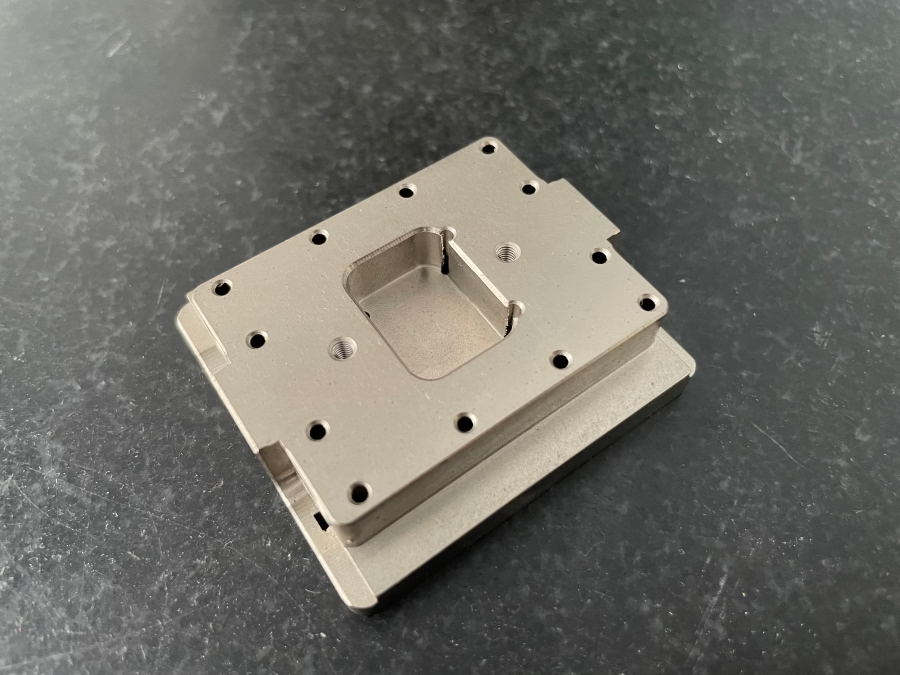

Custom Auto Spare Parts Custom CNC Manufacturing

GreatLight is a professional and experienced precision Custom Auto Spare Parts manufacturer in China, renowned for delivering exceptional custom parts for the automotive and engineering sectors. Specializing in 5-axis CNC machining, we produce high-precision auto spare parts, engine components, and aluminum machining parts with tolerances as tight as 0.001mm. Our ISO 9001:2015 certified facility ensures consistent quality for both metal and plastic custom components.

As a leader in CNC manufacturing, we excel in rapid prototyping and low-to-mid volume production. Utilizing advanced 3-, 4-, and 5-axis CNC technology, we transform complex 3D designs into functional prototypes or finished parts within days—ideal for urgent projects or high-stakes presentations. Whether you need intricate aluminum engine blocks or durable auto spare parts, GreatLight combines speed, precision, and affordability. Trust us for reliable solutions that drive innovation without compromising on accuracy.

Description

Custom Auto Spare Parts by GreatLight: Precision Engineered for Automotive Excellence

Introduction: Redefining Precision Custom Auto Spare Parts Manufacturing

At GreatLight CNC Machining Center, we specialize in high-precision, custom-engineered solutions for the automotive industry. As an ISO 9001:2015 certified leader in China, we deliver unparalleled 5-axis CNC machining services for Custom Auto Spare Parts, engine components, and aluminum prototypes. With tolerances as tight as ±0.001mm, we transform complex designs into flawless functional parts, ensuring performance, durability, and innovation. Our expertise spans rapid prototyping to large-scale production, backed by a commitment to quality, speed, and client collaboration.

Core Product Features

- Advanced 5-Axis Machining Capabilities

- Multi-Angle Precision: Simultaneously machine complex geometries (e.g., turbine blades, cylinder heads) without repositioning, reducing errors by 70%.

- Material Versatility: Expertise in aluminum alloys (6061-T6, 7075), stainless steel, titanium, and engineering plastics like PEEK.

- Surface Excellence: Achieve finishes down to Ra 0.2μm for critical automotive interfaces.

- Customization Without Compromise

- Tailored solutions for OEMs, motorsports, and aftermarket suppliers.

- Support for 3D CAD/CAM designs (SolidWorks, AutoCAD) with DFM feedback to optimize manufacturability.

Suitability: Applications & Industries

- Automotive & Motorsports: Engine blocks, suspension components, turbocharger housings.

- Aerospace: Lightweight structural parts with high strength-to-weight ratios.

- Industrial Machinery: Wear-resistant gears, hydraulic valves.

Ideal for prototypes requiring <5-day turnaround or production batches of 50–10,000 units.

Quality & Accuracy Assurance

- Tolerance Standards: ±0.001mm for critical dimensions.

- Inspection Protocols:

- CMM (Coordinate Measuring Machines) for 3D profiling.

- Laser scanning and surface roughness testers.

- Certifications: ISO 9001:2015, with material traceability via mill test reports.

Technical Parameter Tables

| Machining Specifications | Parameter | Range/Capability |

|---|---|---|

| Tolerance | ±0.001mm – ±0.02mm | |

| Part Size | Up to 600mm × 500mm × 300mm | |

| Surface Finish | Ra 0.2μm – Ra 3.2μm | |

| Batch Size | Prototype to 10,000+ units |

| Material Properties | Material | Tensile Strength | Density (g/cm³) | Primary Use Cases |

|---|---|---|---|---|

| Aluminum 7075 | 572 MPa | 2.8 | High-stress engine mounts | |

| Stainless Steel 304 | 505 MPa | 8.0 | Exhaust systems | |

| PEEK | 90 MPa | 1.3 | Heat-resistant gaskets | |

| Titanium Gr5 | 895 MPa | 4.5 | Aerospace fasteners |

Machining Process & Instructions

- Design Validation: Upload CAD files → Our engineers review for manufacturability (48-hour feedback).

- Material Selection: Recommend optimal alloys/plastics based on load, temperature, and corrosion resistance.

- 5-Axis Machining: Utilize DMG Mori or HAAS CNC centers for high-speed, multi-plane cuts.

- Post-Processing: Deburring, anodizing (e.g., MIL-A-8625 for aluminum), or heat treatment.

- Quality Control: Final inspection with automated CMM reports.

Customization Guide

- Step 1: Share drawings/samples via email or our portal.

- Step 2: Receive a feasibility report with cost and lead time.

- Step 3: Approve design → Production initiates in 24 hours.

Prototype lead time: 3–7 days. Bulk orders: 15–30 days.

Competitive Advantages

1. Price Efficiency

- Cost Reduction: Bulk-order discounts (15–30% for 1,000+ units).

- Zero Hidden Fees: Quotations include tooling, finishing, and shipping.

2. Rapid & Reliable Delivery

- 98% on-time delivery rate via optimized logistics (DHL/FedEx).

- Urgent prototyping: 72-hour expedited service.

3. Unmatched Technical Support

- Dedicated project managers for real-time updates (WhatsApp/email).

- 24/7 engineering assistance for design modifications.

4. Supply Chain Resilience

- Strategic partnerships with Alcoa (aluminum) and Sandvik (tooling).

- Risk mitigation: Dual-sourcing for critical materials.

Quality Control & Certifications

- In-House Lab: Spectrometers for material verification; stress-testing equipment.

- IP Protection: NDAs, encrypted data transfers, and facility access controls.

- Continuous Improvement: Six Sigma processes to reduce defect rates (<0.1%).

After-Sales Commitment

- Lifetime Technical Consultation: Free troubleshooting for part integration.

- Rework Guarantee: 30-day warranty for dimensional inaccuracies.

Why Choose GreatLight?

- Precision Leadership: 5-axis technology for geometries impossible with 3-axis systems.

- Scalability: From one-off prototypes to high-volume production.

- Holistic Solutions: Combining cost, speed, quality, and risk management.

Contact Us Today!

Elevate your automotive projects with CNC machining excellence. Reach out for a free quote and DFM analysis:

- Phone/WhatsApp: +86 180 2756 7310

- Email: [email protected]

- Website: glcncmachining.com

GreatLight CNC Machining Center: Where Innovation Meets Precision.

Additional information

| Product Type | Auto Spare Parts |

|---|---|

| Application | Engine Parts |

| Material | |

| Manufacturing Process | CNC Machining |

| Machining Technology | 5 Axis |

| Customization | Custom |

| Supplier | GreatLight CNC Machining Center |

| Marketplace | GreatLight |