Description

$0.15

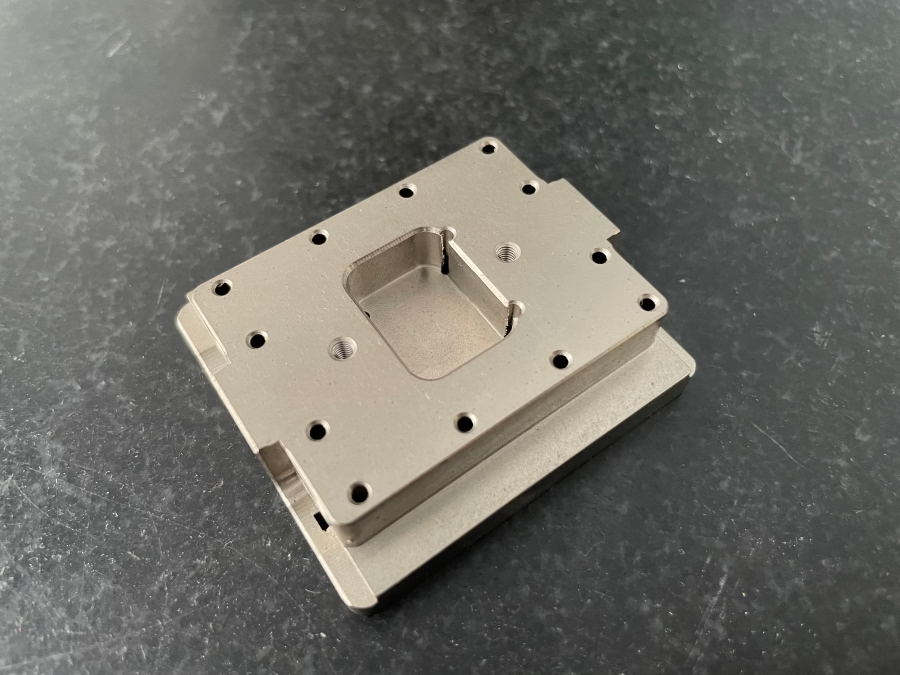

CNC Machining Prototype Service Savannah

GreatLight is a professional & experienced precision CNC Machining Prototype Service in Savannah, specializing in high-accuracy manufacturing for aerospace, automotive, industrial, and prototyping applications. With ISO 9001:2015 certification, we deliver precision CNC Machining Prototype Service Savannah with tolerances as tight as 0.001mm, ensuring exceptional quality and reliability.

Our expertise spans materials like aluminum, stainless steel, brass, and alloys, catering to industries demanding durability and precision. Whether you require custom prototypes for rapid development or large-scale production of complex parts, our advanced 3-, 4-, and 5-axis CNC systems transform 3D designs into finished products in days.

Key Advantages:

- Unmatched Precision: Tight tolerances for critical applications.

- Versatile Materials: Aluminum, steel, brass, alloys, and more.

- End-to-End Solutions: From rapid prototyping to full-scale industrial production.

- Industry-Leading Speed: Fast turnaround without compromising quality.

As a leader in CNC machining, GreatLight combines cutting-edge technology with decades of expertise to meet the highest standards. Trust us for innovative, reliable solutions—from concept to completion. Discover why we’re one of China’s top rapid prototyping partners.

Description

Precision Beyond Limits: GreatLight’s CNC Machining Prototype Service Savannah

Welcome to the future of precision engineering—where dreams become reality with untouched accuracy. GreatLight CNC Machining Center, an ISO 9001:2015 certified leader in Savannah, is your gateway to flawless components, whether for aerospace breakthroughs, automotive innovation, or high-stakes prototypes. With cutting-edge 5-axis capabilities and sub-0.001mm tolerances, we transform complex 3D designs into tangible excellence in days—not months. Let’s redefine your project’s boundaries together.

Why Choose GreatLight? Unmatched Advantages in Every Detail

- Mastery Across Materials: Aluminum, Stainless Steel, Brass, Copper Alloys, Titanium, and beyond—handled with equal finesse.

- Rapid Turnaround: Prototypes in 3–5 days; production at full scalability.

- Zero Compromise on Quality: Multi-layered quality assurance and IP protection.

- Cost Efficiency: Factory-direct pricing without sacrificing precision.

- Holistic Support: End-to-end engineering guidance from concept to installation.

Materials: Performance Profiles at a Glance

Select the ideal material for your application:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Key Applications | Corrosion Resistance |

|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | Aerospace brackets, automotive parts | Excellent |

| Stainless 304 | 8.0 | 515 | Medical devices, food equipment | Superior |

| Brass C36000 | 8.5 | 420 | Electrical connectors, marine hardware | Good |

| Titanium Ti-6Al-4V | 4.5 | 950 | Jet engines, high-stress components | Exceptional |

| Inconel 718 | 8.2 | 1300 | Rocket nozzles, deep-sea submersibles | Outstanding |

Technical Capabilities: The Power Behind Precision

Advanced Machinery We Deploy:

- 5-Axis CNC Machines: For intricate geometries (e.g., turbine blades, medical implants).

- High-Speed Machining Centers: Aluminum components at 1000mm/s feed rates.

- Swiss Lathes: Micron-level pins, connectors, and fasteners.

- CMM Inspection: 3D laser scanning with ±0.001mm accuracy.

- EDM & Wire-Cut: Hardened tool steel and exotic alloys.

Supported Processes:

- Milling, Turning, Drilling, Tapping, Reaming, and Thread Cutting.

- Surface Treatments: Anodizing, PVD Coating, Passivation, and Hardening.

- Assembly & Integration: Post-processing with adhesive bonding or welding.

Machining Instructions: Your Blueprint to Perfection

- Design Submission: Provide 2D/3D files (STEP, IGES, or SolidWorks). Our engineers optimize for manufacturability.

- Material Selection: We advise on thermal conductivity, strength, and cost-efficiency.

- Toolpath Planning: Custom strategies to minimize distortion and maximize surface finish.

- Prototyping Phase: Dry-fit and clearance checks before final production.

- Quality Assurance: Real-time monitoring via in-process CMM scans.

- Packaging: Anti-corrosion films for steel/stainless, static-resistant for brass.

Custom Guide: Turning Ideas into Tangible Excellence

From Concept to Contractor:

- Consultation: Share your vision—complex assemblies or single components?

- Quote & Timeline: Get a detailed price quote and due date within 24 hours.

- Design Validation: We flag issues (e.g., undercuts, thin walls) early.

- Production: Automated scheduling ensures no bottlenecks.

- Delivery: Track shipments via real-time logistics dashboards.

Quality & Accuracy: Our Non-Negotiables

- Tolerances: Down to ±0.001mm (0.1 microns) for critical aerospace parts.

- Surface Finish: Ra 0.2µm achievable on aluminum; Ra 0.8µm on steel.

- Certifications: ISO 9001:2015, AS9100 (aerospace), and ISO 13485 (medical).

- QC Process:

- Pre-production FMEA analysis.

- In-process optical inspection.

- Final 100% dimensional verification.

- Destructive testing for aerospace/medical batches.

Price Advantage: Precision Without Compromise

- Volume Savings: Tiered pricing from prototypes to 10k+ units.

- Material Savings: Scrap reduction via nesting optimization.

- Tooling Efficiency: Reusable holders cut per-part costs by 30%.

- Transparent Quotes: No hidden fees—just fair, competitive rates.

Example: 500 aluminum brackets (5-axis) from $2.50/unit (≥500).

Delivery Cycle & On-Time Performance

- Prototypes: 3–5 days (global via DHL/FedEx).

- Low Volumes (100–500 units): 7–10 days.

- Mass Production (1k+ units): 14–21 days with JIT shipping.

- On-Time Rate: 98.7% (2023 performance).

- Buffer Stocks: Safety inventory for repeat orders.

Communication & Technical Support: Seamless Collaboration

- Dedicated Account Managers: Single point of contact, 24/7.

- Real-Time Dashboards: Track design, machining, and shipment status.

- Technical Reviews: Virtual meetings with our engineering team.

- After-Sales Care: Lifetime support for design adjustments or reworks.

- Language Support: English, Mandarin, Spanish, and Arabic.

Confidentiality & IP Protection: Your Trust Is Sacred

- NDA Agreements: Binding secrecy contracts before R&D begins.

- Data Encryption: AES-256 protocols for digital files.

- Access Control: Restricted facility entry for sensitive projects.

- IP Rights: All designs remain your property.

Supply Chain Stability: Resilience in Uncertainty

- Diversified Suppliers: 12+ metal refineries across Europe, North America, and Asia.

- Inventory Buffer: 3 months of raw materials on-site.

- Risk Mitigation: Blockchain-tracked shipments and alternate logistics.

- Disaster Recovery: Backup generators and redundant networks.

Our Promise: End-to-End Problem Solvers

GreatLight doesn’t just machine parts—we eliminate roadblocks.

- Quality Roadblocks: Real-time defect analysis via AI-driven inspection.

- Cost Pressure: Value engineering to slash expenses by 20–40%.

- Timeline Crunches: 24/7 shifts for same-day rush orders.

- Technical Gaps: Full-stack solutions from design to assembly.

Get Started Today—Where Precision Meets Purpose

Transform your design into reality with China’s trusted CNC engineering partner.

- Phone: +86 180 2756 7310 (WhatsApp)

- Email: [email protected]

- Website: glcncmachining.com

GreatLight CNC Machining Center

ISO Certified | Aerospace-Grade | Rapid Prototyping Leader

Additional information

| Application | Aerospace, Automotive |

|---|---|

| Material | |

| Process | CNC Machining |

| Service Type | Custom Prototype, Industrial CNC Production |

| Accuracy | High |