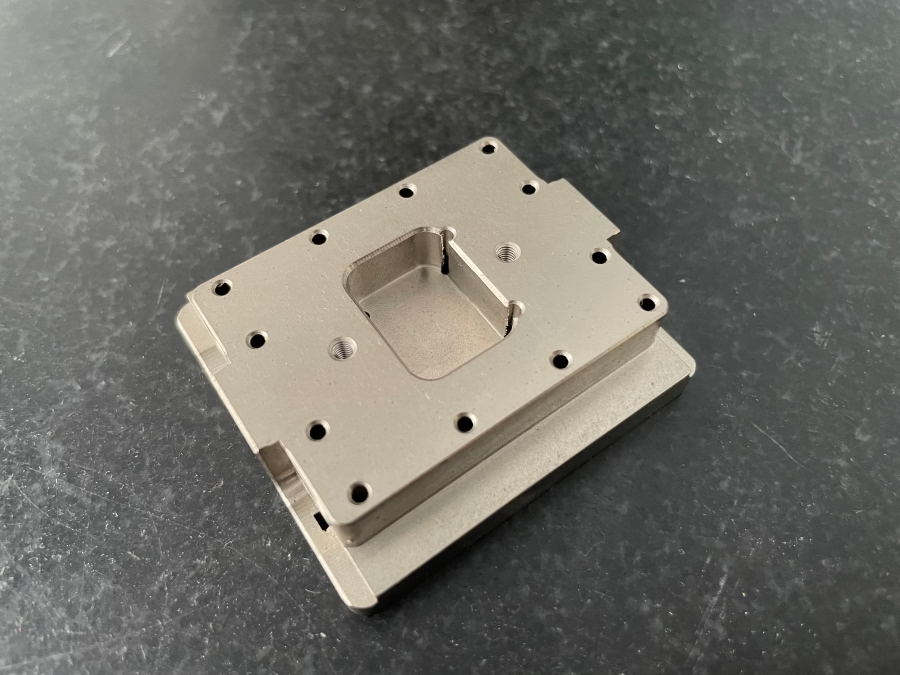

High-Precision CNC Machined Aluminum Alloy Impeller

Optimize Fluid Dynamics with Aerospace-Grade Engineering

Crafted for peak performance in demanding environments, our Aluminum Alloy Impeller leverages advanced CNC precision machining to deliver unmatched efficiency, durability, and reliability. Ideal for aerospace, automotive turbocharging, industrial pumps, and HVAC systems, each impeller is engineered to maximize fluid/gas movement while minimizing energy loss.

🔑 Key Features

- Material Excellence: Aerospace-grade 6061/7075 aluminum alloy for superior strength-to-weight ratio, corrosion resistance, and thermal stability.

- Micron-Level Precision: CNC machined to tolerances as tight as ±0.01mm, ensuring perfect blade geometry for smooth, turbulent-free flow.

- Dynamic Balance Optimized: Computer-verified balancing reduces vibration, extending component lifespan and operational safety.

- Customizable Designs: Tailor blade angles, hub configurations, and dimensions (diameters from 20mm to 500mm) to your exact specifications.

- Surface Perfection: Anodized or polished finishes available to resist wear, cavitation, and chemical degradation.

⚙️ Applications

- Turbochargers & Superchargers

- Centrifugal Pumps & Compressors

- Hydraulic Systems & Cooling Fans

- Wind Tunnels & Ventilation Units

✅ Quality Assurance

- Rigorous Testing: 100% inspected via CMM (Coordinate Measuring Machine) and dynamic balance testing.

- Certified Compliance: Meets ISO 9001, AS9100, and RoHS standards.

- Rapid Prototyping: From CAD model to functional part in 72 hours (MOQ: 1 unit).

Elevate Your Machinery’s Efficiency—Request a quote today for custom CNC-machined impellers engineered to outperform. ✨

Precision isn’t just a process—it’s our promise.

Automotive Prototyping Solutions –

500 injection molds delivered in 15 days – **CNC machining** at warp speed!