Release the power of precision: Master plasma CNC cutting

In the demanding world of metal manufacturing, speed, accuracy and versatility are crucial. Despite the various technologies competing for advantages, plasma CNC cutting remains a powerful and essential solution for countless applications. For manufacturers that solve complex projects, mastering plasma CNC cutting, especially using advanced features such as five-axis control, can unlock new echelons of efficiency and capability. At Greatlight, we hone this mastery, leveraging cutting-edge technology and deep expertise to transform raw metal into complex high-quality components.

More than just the Hot Torch: The Science Behind Plasma Cutting

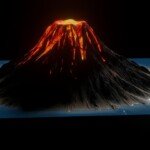

The core of plasma-cut uses a conductive core – usually compressed air, but also uses special gases of nitrogen or argon (such as argon) that can overheat it to an extremely high energy state, thus creating plasma. This plasma jet is produced in a narrow nozzle and is fully charged by a powerful arc, reaching temperatures above 20,000°C (36,000°F), melting the metal almost instantly. Meanwhile, a high-speed airflow blows away the molten metal, forming a KERF (cut).

But mastering is not just about plasma production; Control it With extraordinary precision. This is where the CNC (Computer Numerical Control) conversion process is. The CNC system converts complex digital designs (CAD files) into precise machine movement and cutting parameters. Plasma Torch became a robot sculptor, dominated by code to create shapes with significant accuracy and repeatability.

Ways to master: Key factors

Mastery in achieving plasma CNC cutting goes beyond basic machine settings. It involves in-depth knowledge and control over interconnected factors:

-

Materials Important: Different metals (carbon steel, stainless steel, aluminum, copper alloy) react differently to plasma. Mastering involves understanding:

- Conductivity: Influences the start and stability of the arc.

- thickness: Determines the required plasma power (amperes), gas type, flow rate and cutting speed. Thicker materials require more power and slower speeds.

- Surface condition: Rust, paint or scale may interfere with the start and cutting quality of the arc.

- Thermal characteristics: Affect the Heat Affected Zone (HAZ) size and potential distortion.

-

Torch technology and consumables: The core of the system. Precise torch height control (THC) is Critical In order to maintain the optimal confrontation distance with the workpiece, it directly affects the quality of the cut, the life of the consumed amount and the process safety. The amount of consumption during cutting (electrodes, nozzles, rotating rings, fixed covers) must be worn and carefully selected and maintained. Using the right component as material and thickness is not negotiable for consistency.

-

Gas selection and dynamics: The choice of plasma gas and shield gas (if used) has profound effects:

- Cut quality: Square edges, dripping to form, surface finish.

- speed: Reduce efficiency.

- Consumable life: Certain gases increase wear rate.

- Material Compatibility: Specific gases are essential for oxidation or non-oxidation cleavage. Mastering means optimizing gas type, pressure (Pierce vs. buck) and flow rate.

-

Fine-tuning parameters: Voltage, Ampere, Cutting Speed, Puncture Height, Puncture Delay Time, Kerf Compensation – Each parameter is interdependent. Master cutting diagrams involving experimental development and perfection to understand the different material/thickness combinations and how each adjustment affects edge quality, drops, bevels, and productivity.

- CNC precision and path optimization: The stiffness, accuracy and dynamic motion control of the machine are fundamental. Complex CNC software allows:

- Nested Optimization: Maximize material use by intelligently laying out parts.

- Puncture Strategy: Minimize damage to the starting point (e.g. arc arc, lead insertion).

- Angle and small function processing: Adjust the speed and burn technique to prevent rounding or melting. Leap: Five-axis plasma CNC cutting – mastering the true rays

Traditional three-axis plasma (X, Y, Z motion) is good at plane curves Five-axis CNC Plasma cleavage completely changes function by adding two axes of rotation (typically A and B). This allows the torch head to be tilted and rotated, thus unraveling the profound benefits of showing true mastery:

- Complex contours: Precisely cut beveled edges, bevels and complex shapes Single Settings – Standard plasma is impossible. Think about the ends of the pipe, flanges, transition sheets and complex structural components that require tilting edges for welding.

- Reduced minor operations: Eliminate or significantly reduce the need for time-consuming manual grinding or milling to achieve the desired angle, reducing lead time and cost.

- High-quality edge quality: Even on the contour surface, maintain the optimal torch angle angle throughout the cutting path, resulting in a cleaner, more consistent edge and reduce dripping and beveling. This is crucial for welding preparation quality.

- Extended range of materials: Handling complex parts made from thicker materials in which it is very difficult or inconsistent to achieve a clean bevel manually.

- Accessibility: Cut complex features or angles on uneven prefabricated parts or components. This is a game changer for fixing and customizing modifications.

Great Advantages: Accurate Expertise

At Greatlight, plasma CNC cutting mastery is not a slogan. It is embedded in our DNA and technology infrastructure. We invest in state-of-the-art five-axis CNC plasma cutting systems and carefully maintain their peak performance. Our experienced engineers and technicians are not only operating machines; they have an in-depth understanding of plasma physics, materials science, kinematics and CNC programming.

- Advanced Technology: Our cutting platform features ultra-fine motion control, HD plasma sources (for cutting in thinner metered sizes), and a refined THC system for unwavering accuracy and repeatability.

- Methods of matter agnostic: From standard carbon steel and aluminum to challenge alloys such as titanium and copper, we customize plasma processes – gas mixtures, power, speed, speed and torch direction – for best results.

- Process optimization of engineering leadership: We do not rely on common settings. Our team analyzes each project, selects the best cutting strategy (including leveraging our five-axis functionality, beneficial five-axis functionality) and performs perfect micro parameters. We prioritize minimizing HAZ, ensuring welded edges, and achieving dimensional tolerances consistently.

- Seamless integration: Plasma cleavage is usually just the first step. As a full-service manufacturer, Greatlight offers a comprehensive aftermath – precise machining, grinding, burring, heat treatment and a wide range of surface finishes – all under one roof. This ensures fit, function and ultimate aesthetics meet the highest standards without the hassle of coordination.

- Speed and value: Our mastery translates directly into efficiency. Fast programming, optimal nesting, minimized waste, reduced set/fixed time, and eliminate auxiliary operations on bevels means we deliver complex, high-quality parts faster and more cost-effectively. In Greatlight, "custom" Not saying "Slow and expensive."

Conclusion: Improve metal manufacturing

Plasma CNC cutting is the cornerstone of modern metal processing, but its true potential is through mastery-a complex understanding of processes, strict control of variables, and investment in advanced technologies. This is further enhanced by the emergence of five-axis plasma cutting, thus creating geometrically complex parts directly from the plate with unparalleled accuracy and efficiency.

For engineers, designers and manufacturers trying to push the possible boundaries of metal parts, it is crucial to work with companies with real plasma CNC cutting. Greatlight combines state-of-the-art five-axis CNC capabilities with deep-rooted expertise and a comprehensive service approach. We don’t just cut metal; we designed the solution.

Stop compromising complexity or cost. Leverage the power of precise plasma CNC mastery. Contact Greatlight today to discuss how our advanced manufacturing capabilities bring your most challenging precisely machined metal parts to life – faster, smarter, and at truly competitive prices.

FAQ: Plasma CNC shear mastery

Q: Which type of metal can be cut out with plasma CNC?

one: Our advanced plasma systems have a wide range of processing, including carbon steel, stainless steel, aluminum, brass, copper, and titanium (such as titanium). We select the appropriate plasma gas, power levels and cutting parameters specifically for optimal results using each material type and thickness.

Q: How big metal can you cut into?

one: Functions vary according to the power of the plasma system. We have equipment to clean carbon steel from thin instrument (1mm) until very thick sections over 100mm (4 inches). The specific achievable thickness maximum depends on the material and required edge quality tolerances – Consult our engineering team for details.

Q: What are the main advantages of five-axis plasma on standard (triaxial) plasma?

one: Five axes stand out in three key areas: 1) Complex contours: Cut precise bevels, angles and composite 3D shapes, cut directly from a flat plate in one setup. 2) Reduced secondary operations: Eliminates the need for manual grinding or milling at critical angles that are usually required to be soldered. 3) Premium edge quality for sloped edges: Maintain optimal torch angle throughout the cutting process to ensure a cleaner, more consistent welding edge even on the contoured surface.

Q: What kind of accuracy can I expect?

one: GRESTHIMENG prioritizes high-precision cutting. We achieve excellent dimensional accuracy and repeatability, using advanced five-axis CNC systems and high-definition plasma technology, where appropriate. Tolerances depend on material, thickness, part size and geometry, but we always maintain tight tolerances that are suitable for industrial applications and preparation for direct welding. Discuss your specific tolerance requirements for a detailed assessment.

Q: Do you provide post-processing/complete services after plasma cutting?

A: Yes, absolutely. As a full-service manufacturer, Greatlight offers a comprehensive set of post-processing services. This includes precision machining (milling/turning), precision machining and burring for smooth edges, heat treatment (annealing, hardening, speed regulation), and various surface finishes (painting, powder coating, electroplating, anodizing, etc.). We handle all this efficiently under one roof.

Q: How does Greatlight ensure quality?

one: Quality is basic. Our processes include rigorous CNC program verification, meticulous machine calibration and preventive maintenance, the use of precise measurement equipment (calipers, microns, CMMs required), and final inspection for customer drawings/specs. We operate under strong quality management principles.

Q: How fast can I customize the parts?

one: Speed is the core advantage of plasma cutting combined with our process mastery. Our advanced nesting maximizes material use and minimizes cut-down time, and our integrated manufacturing approach greatly reduces processing latency. Although delivery times vary according to the complexity and quantity of the project, we specialize in research Quick turnaround Used to customize precision parts without sacrificing quality. Please contact us with your requirements for specific timeline estimation.

Q: Are the cost-effectiveness of five-axis plasmas compared to other methods?

one: Five-axis plasma is usually obvious for parts that require complex angle features or bevels More Cost-effective. It eliminates expensive secondary machining operations (milling or grinding bevels), reduces overall setup time and minimizes material handling and coordination. Even for simple parts, the speed and material utilization efficiency of CNC plasma often make it highly competitive. We provide competitive quotes based on the optimization cost of your specific project.