Transmission components used in wind turbines (WTG for short) are all high-load equipment.

Static and dynamic loads will be reflected in the pitch, roll and yaw movements of the tower top and in the structural deformation of the entire drive chain.

Various dynamic reactions occur on the transmission components: spontaneous vibrations of the rotor blades, load changes as each blade rotates, and inconsistent air turbulence acting on the rotor.

All of this can lead to distortion of transmission components and torque fluctuations. The fluctuating torque will far exceed the rated torque value in an instant. Figure 1 shows the load-induced deformation of the rotor, tower, and transmission.

Figure 1: Image showing load-induced transmission deformation (Image source: FVA, Workbench)

Wind turbine drives must be able to withstand static and dynamic loads for decades. Only with modern simulation methods and knowledge of transmission loads can transmission components be optimized to ensure a service life of 20 or 25 years with a utilization rate of 98%.

In addition to advances in simulation tools, advances in materials science for high-purity steel have also contributed to the success of the driveline.

method

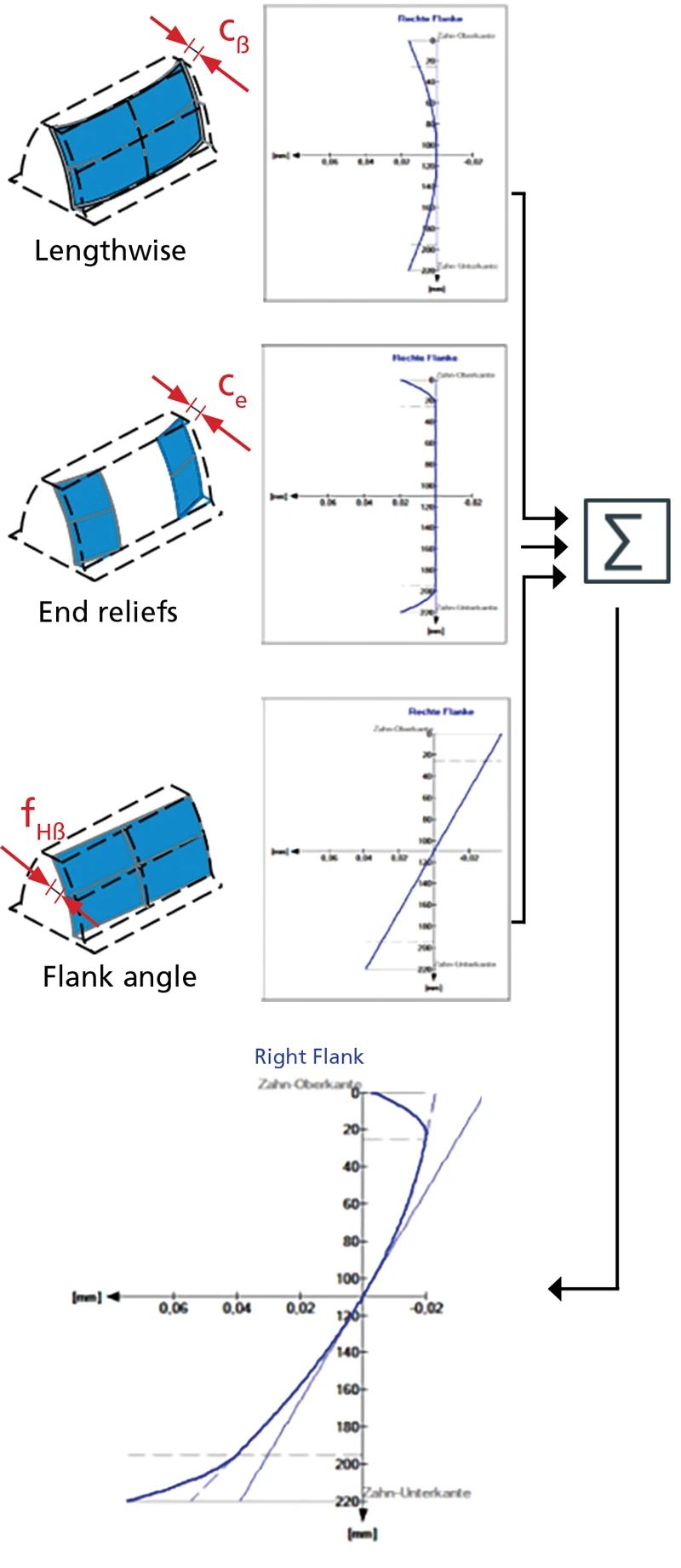

Only according to the structural deformation caused by the load can the design engineer set the optimal topography of the tooth surface of each gear, so as to ensure that the pressure when contacting the tooth surface teeth does not exceed the permissible range of material parameters under various load conditions. During production, it is necessary to ensure that the shape of the tooth surface is manufactured accurately. Figure 2 shows a typical modification of a tooth surface.

Figure 2: Typical change in gear tooth surface

Due to the large modulus and width of teeth, form grinding has become the standard method for grinding hard tooth surfaces, allowing a high degree of freedom in tooth surface design.

Being able to change the tooth surface in actual production is a prerequisite for gear design.

Gear production software for Hofler’s RAPID cylindrical gear grinding machines helps design engineers convert expected tooth surface shapes into feasible tooth surface geometries.

The simulation of the system can therefore be carried out under realistic conditions. This prerequisite also facilitates production, as it eliminates the need for an iterative process between design and production to determine whether the gear actually produced meets the required precision requirements.

production ready process

Cost pressure and production growth often lead to process optimization, and ultimately the processing technology becomes powerful and efficient. For the mass production of large gears, the process level and production efficiency of machine tools play equally important roles. Machine tool temperature stability is essential for both. The development of RAPID series gear grinding machines began 20 years ago. Since then, experience has been accumulated and optimizations have been carried out several times.

But the frame and the column of the machine have never changed. They are always made of mineral cast iron.

This includes quartz particles, quartz sand and mineral dust, as well as a small amount of epoxy resin glue. This material gives high-precision grinding machines exceptional material properties: low thermal conductivity, high thermal capacity and ten times greater thermal attenuation than gray cast iron.

Based on this, the dimensional accuracy of large gears within a narrow tolerance range can be guaranteed regardless of the processing time. Excellent damping characteristics ensure high dynamics of the CNC axes, a prerequisite for efficient production.

Gear Alignment Solutions

Heat treatment deformation should be detected before machining, so that the grinding process can be designed to avoid unnecessary “empty tool strokes” and microstructural damage caused by excessive tool feed. To do this, you must move the stylus while detecting the maximum margin.

But what if the maximum tolerance is at the root of the tooth, at the top of the tooth, at the top or at the bottom of the tooth?

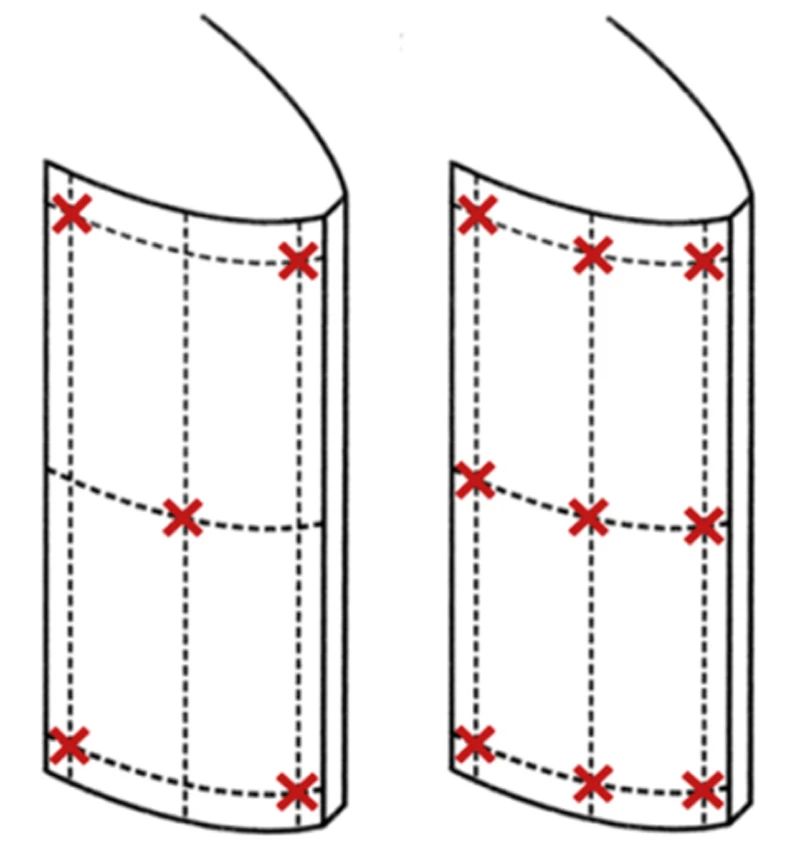

The greater the modification required to the tooth flank, the more problematic machining becomes. Extended alignment analysis provides a solution. During the analysis, several measurement points can be defined (see Figure 3). At the end, the position of the grinding wheel for uniform grinding can be calculated from the measurements.

Figure 3: Example of 5 points Example of 9 points Different positions of the measuring points for centering

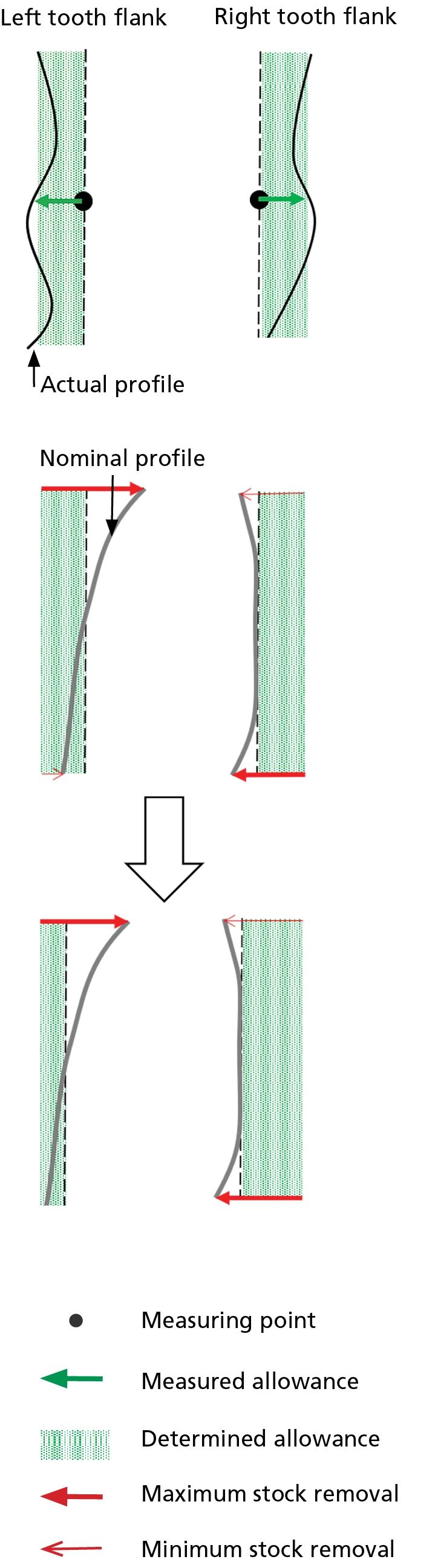

Figure 4 shows the principle using a single tooth as an example. The unmodified nominal tooth profile is the starting point for assessing tolerances. The margin is the difference between the position measured during measurement and the unmodified position of the tooth profile.

The upper left of Figure 4 shows a single point measurement as an example. When a multi-point measurement is performed, the margin position is different. There is an inclined line segment between two measurement points and a parabola between three measurement points.

Figure 4: Removal of material and material

To determine the material removal, the existing stock and the nominal profile of the tooth to be machined must be taken into account (see lower left part of Figure 4). It is clear that material removal is evolving. If grinding is done in this manner, only the upper left portion will be ground in the first few passes and no grinding shrinkage will occur on the right tooth surface.

In order to minimize the number of passes for grinding the tooth gap, the allowance can be cycled in such a way that the maximum allowance on the left and right tooth surfaces is consistent and its value is as small as possible. Here it is necessary to ensure that the material removal rate is not lower than the minimum value (see the lower right part of Figure 4). With this centered position, the left and right sides can be ground in the first few passes.

The more tooth gaps on the circumference and tooth width are used to calculate the centering position, the closer the grinding allowance for the current thermal deformation is to the minimum grinding allowance. The smaller the grinding allowance, the shorter the processing time.

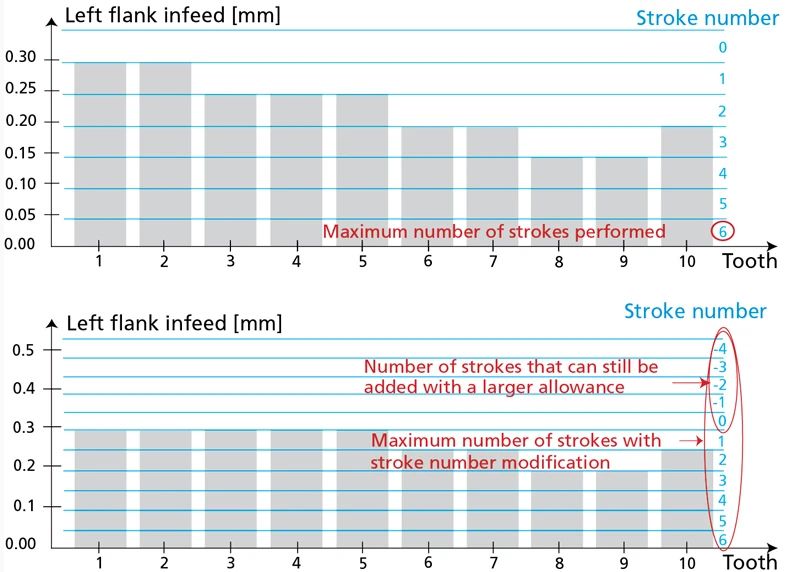

Figure 5: Optimized process parameters

Process Design Solutions

Since the more reliable the stock assessment, the more likely it is that maximum removal will be achieved, and the number of passes required to grind each tooth space can be determined automatically using different numbers of strokes. This avoids unnecessary passes and material removal beyond the feed limits. Because the number of tool passes will be automatically increased for tooth spaces with large margins.

All measurement data regarding stock and number of passes is presented to the operator (see Figure 5). Rather than blindly relying on algorithms, Gear Production software’s digital assistance systems provide optimal support to the operator.

Archiving and quality assurance solutions

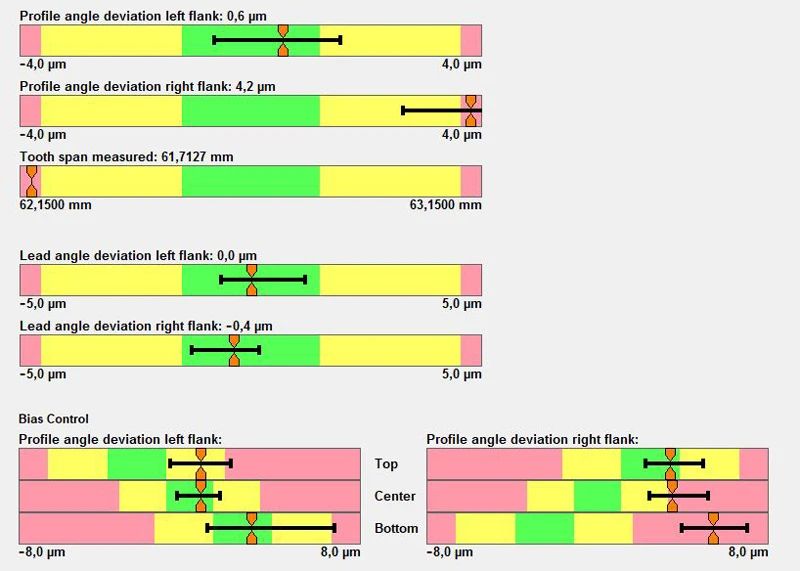

After the grinding process, the gears can still be automatically measured directly on the grinding machine. The correction values of machine tool settings generated based on the report can minimize production deviations as much as possible. Since we are machining tooth surface geometries that can actually be produced, there is no need to use an approximate scheme to calculate correction values: the algorithm will produce accurate values.

In principle, it does not matter whether the measurement results come from an online inspection system of the gear grinding machine or from a gear measuring center. In both cases, if corrections are necessary, the operator is informed before processing the next part (see Figure 6). The different deviations are displayed using the color display of the traffic lights (green, yellow and red) and their meaning is very clear.

automation

Planetary gears weighing up to 2.5 tonnes are extremely common in wind turbines. Automated systems are well suited to this type of machinery. By cooperating with users, although the processing of large-sized wind gears is more difficult than that of mass-produced small gears, appropriate automation solutions can be adopted. As the part is too heavy, it is recommended to use a chassis type loading and unloading device. In order to ensure that the automation system can be connected to the machine tool, it is necessary to adjust the protective cover of the machine tool and add protective devices in accordance with the Machinery Directive regulations. In addition to workpiece processing, the safety measures of the automatic loading and unloading device of the gear grinding machine should be strengthened to ensure data consistency and precise clamping and release of workpieces on the workpiece table. machine tool.

Once the part is clamped on the support, the measuring system integrated into the machine tool detects runout and axial concentricity. If the measured value exceeds the set tolerance, the position will be changed and tightened. If the clamping tolerances are still not met, the part is unloaded from the machine and series production is interrupted.

Figure 6: Visualization of production gaps

in conclusion

Efforts to reduce production costs and improve process productivity have, on the one hand, reduced the distance between development and design, and on the other hand, broken the restrictions imposed on mass production of large gears.

Mass production of large gears cannot simply be applied to designs from other sectors, such as the automotive industry. However, the principles are the same, and reliable gear design and processing solutions can create powerful processing technology.

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.