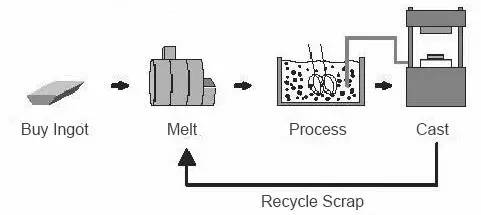

1. Casting

A production method in which liquid metal is poured into a mold cavity matched to the shape and size of the part, then cooled and solidified to obtain a blank or part, generally called liquid metal forming or casting.

Process flow: liquid metal → mold filling → solidification shrinkage → casting.

Process characteristics:

1) It can produce parts of any complex shape, especially parts with complex internal cavity shapes.

2) Strong adaptability, no restrictions on alloy types and almost no restrictions on the size of castings.

3) Materials come from a wide range of sources, scraps can be remelted, and equipment investments are low.

4) High scrap rate, low surface quality and poor working conditions.

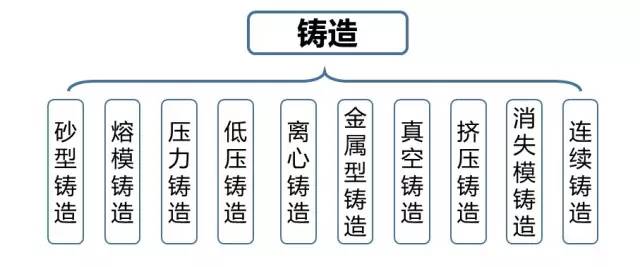

Cast ranking:

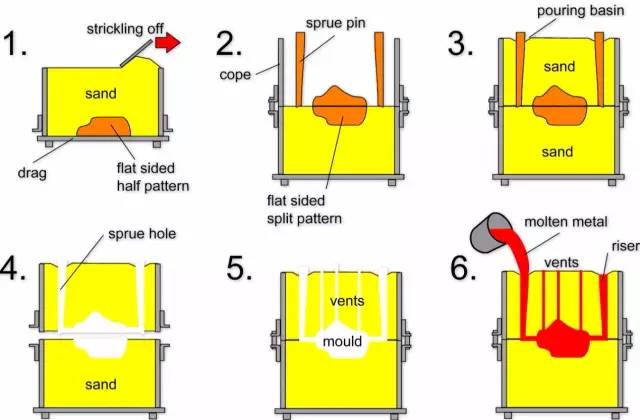

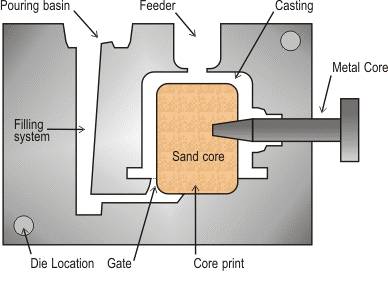

(1) Sand casting

Sand casting: A casting method that produces castings in a sand mold. Castings of steel, iron and most non-ferrous alloys can be obtained by sand casting methods.

Process flow:

Technical characteristics:

1) Suitable for manufacturing blanks of complex shapes, especially those with complex internal cavities;

2) Wide adaptability and low cost;

3) For some materials with low plasticity, such as cast iron, sand casting is the only forming process for manufacturing parts or blanks.

Application: Castings such as cylinder blocks, cylinder heads and crankshafts of automobile engines.

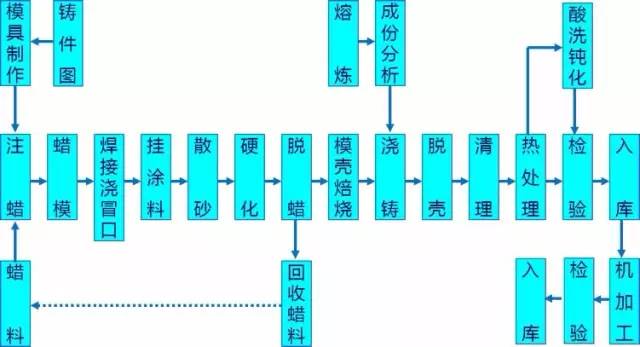

(2) Investment casting

Investment casting: generally refers to making a model from a fusible material, covering the surface of the model with several layers of refractory materials to form a mold shell, then melting the model and extruding the mold shell, thus obtaining a mold without separation surfaces. , which is then grilled at high temperature. Then the casting plane can be filled with sand. Often called “lost wax casting”.

Process flow:

advantage:

1) High dimensional accuracy and geometric accuracy;

2) High surface roughness;

3) It can cast castings of complex shapes, and the casting alloys are not limited.

Disadvantages: The process is complicated and the cost is high.

Application: Suitable for the production of small parts with complex shapes, high precision requirements and difficult to process by other processes, such as turbine engine blades, etc.

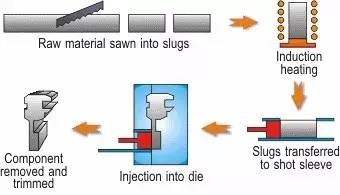

(3) Die casting

Die Casting: It uses high pressure to press molten metal into a precision metal mold cavity at high speed. The molten metal cools and solidifies under pressure to form a casting.

Process flow:

advantage:

1) During die casting, the metal liquid bears high pressure and has rapid flow;

2) The product has good quality, stable dimensions and good interchangeability;

3) High production efficiency and frequent use of die casting molds;

4) Suitable for mass production and good economic benefits.

default:

1) Castings are prone to small pores and shrinkage;

2) Die casting parts have low plasticity and are not suitable for working under impact loads and vibration;

3) When die casting high melting point alloys, the mold life is low, which affects the expansion of die casting production.

Application: Die castings were first used in the automobile industry and instrument industry, and then gradually expanded to various industries, such as agricultural machinery, machine tool industry, electronics industry, the national defense industry, computers, medical equipment, clocks, cameras and everyday life. material. .

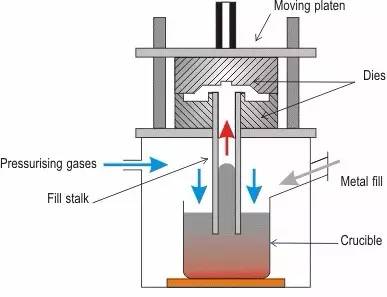

(4) Low pressure casting

Low pressure casting: refers to a method in which liquid metal fills the mold under low pressure (0.02 ~ 0.06 MPa) and crystallizes under the pressure to form a casting.

Process flow:

Technical characteristics:

1) The pressure and speed during casting can be adjusted, so it can be applied to various casting molds (such as metal molds, sand molds, etc.), casting various alloys and castings of different sizes;

2) Through bottom injection mold filling, the molten metal is filled smoothly without splashing, which can avoid gas inclusion and erosion of the mold wall and core and improve the qualification rate molded parts;

3) The casting crystallizes under pressure. The structure of the casting is dense, the outline is clear, the surface is smooth, and the mechanical properties are high, which is especially beneficial for the casting of large and thin-walled parts;

4) The feed riser is omitted and the metal utilization rate is increased to 90-98%;

5) Low labor intensity, good working conditions, simple equipment and easy to achieve mechanization and automation.

Application: Mainly traditional products (cylinder heads, wheel hubs, cylinder frames, etc.).

(5) Centrifugal casting

Centrifugal casting: It is a casting method that pours molten metal into a rotating mold, fills the mold under the action of centrifugal force, and solidifies.

Process flow:

advantage:

1) There is almost no metal consumption in the door system and riser system, thereby improving the process efficiency;

2) No core is needed when producing hollow castings, so the metal filling capacity can be greatly improved when producing long tubular castings;

3) The casting has high density, few defects such as pores and slag inclusions, and high mechanical properties;

4) It is convenient to manufacture composite metal castings of cylinders and sleeves.

default:

1) There are some limitations when used to produce special-shaped castings;

2) The inner hole diameter of the casting part is inaccurate, the inner hole surface is rough, the quality is poor, and the machining allowance is large;

3) Castings are subject to specific gravity segregation.

application:

Centrifugal casting technology was first used in the metallurgy, mining, transportation, drainage and irrigation machinery, aviation, national defense and automobile industries, in at home and abroad, to produce castings in steel, iron and non-ferrous carbon alloys. . Among them, the production of castings such as centrifugal cast iron pipes, cylinder liners and internal combustion engine rings is the most common.

(6) Gravity die casting

Metal Mold Casting: Refers to a forming method in which liquid metal fills a metal mold under the action of gravity and cools and solidifies in the mold to obtain a casting.

Process flow:

advantage:

1) The metal mold has high thermal conductivity and heat capacity, rapid cooling rate, dense casting structure and mechanical properties which are about 15% higher than those of sand castings;

2) Castings with higher dimensional accuracy and lower surface roughness values can be obtained, and the quality stability is good;

3) Because sand cores are not used or rarely used, the environment is improved, dust and harmful gases are reduced, and labor intensity is reduced.

default:

1) The metal mold itself is not breathable, and certain measures must be taken to exhaust the air from the mold cavity and the gas generated by the sand core;

2) The metal mold has no give and cracks are likely to occur when the casting solidifies;

3) The manufacturing cycle of metal types is long and the cost is high. Therefore, good economic effects can only be demonstrated when mass production is carried out in batches.

application:

Metal mold casting is not only suitable for the mass production of complex-shaped non-ferrous alloy castings such as aluminum alloys and magnesium alloys, but also suitable for the production of metal castings and ingots in iron and steel.

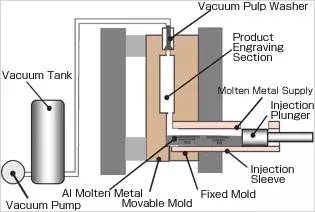

(7) Vacuum casting

Vacuum Casting: An advanced die casting process that eliminates or significantly reduces pores and dissolved gases in die casting parts by removing gas from the die casting mold cavity during the die casting process, improving thus the mechanical properties and the surface. quality of die casting parts.

Process flow:

advantage:

1) Eliminate or reduce pores inside die casting parts, improve the mechanical properties and surface quality of die casting parts, and improve plating performance;

2) Reduce the back pressure of the mold cavity, use lower specific pressure and alloys with poor casting performance, and it is possible to pressure cast larger castings with small machines;

3) Filling conditions are improved and thinner castings can be die cast.

default:

1) The mold sealing structure is complex and difficult to manufacture and install, so the cost is high;

2) If the vacuum casting method is not properly controlled, the effect will not be very significant.

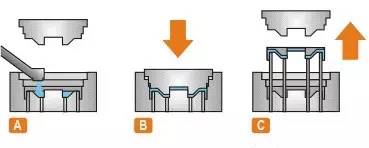

(8) Pressing die casting

Compression casting: It is a method of solidifying and creeping liquid or semi-solid metal under high pressure to directly obtain parts or blanks. It has the advantages of high utilization rate of liquid metal, simplified process and stable quality. It is an energy-saving metal forming technology with potential application prospects.

Process flow:

Direct compression casting: spray coating, alloy casting, mold closing, pressurization, pressure holding, decompression, mold splitting, blank demolding, reset;

Indirect compression casting: spray coating, mold clamping, feeding, mold filling, pressurization, pressure holding, decompression, mold splitting, blank demolding and resetting.

Technical characteristics:

1) It can eliminate internal defects such as pores, shrinkage cavities and shrinkage porosity;

2) Low surface roughness and high dimensional accuracy;

3) It can prevent the occurrence of casting cracks;

4) Facilitate mechanization and automation.

Application: Can be used to produce various types of alloys, such as aluminum alloys, zinc alloys, copper alloys, ductile iron, etc.

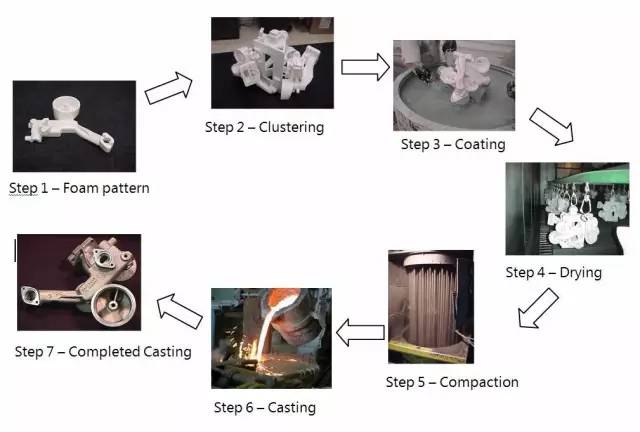

(9) Lost Foam Casting

Lost foam casting (also known as true mold casting): Paraffin or foam models similar in size and shape to the casting are linked and combined into model clusters. After being painted with refractory paint and dried, they are buried in dry quartz sand and vibrated. shape. This is a new casting method that vaporizes the model by pressing it down, and the liquid metal occupies the position of the model, then solidifies and cools to form a casting.

Process flow: Pre-foaming → Foaming → Paint dipping → Drying → Shaping → Pouring → Sand drying → Cleaning.

Technical characteristics:

1) The casting has high precision and does not contain sand core, which reduces processing time;

2) No separation surface, flexible design and high degree of freedom;

3) Clean production, no pollution;

4) Reduce investment and production costs.

application:

It is suitable for producing precision casting parts of various sizes with complex structures. There is no limit to the alloy type and production batch. Such as gray cast iron motor housing, high manganese steel elbow, etc.

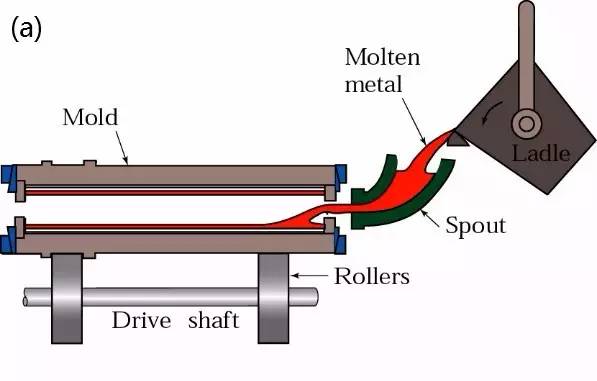

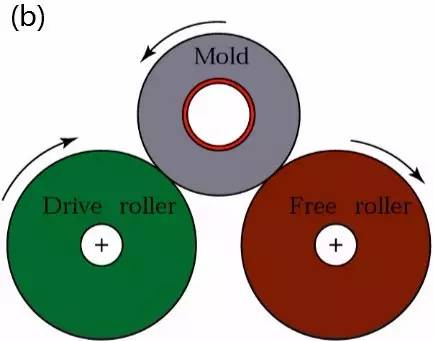

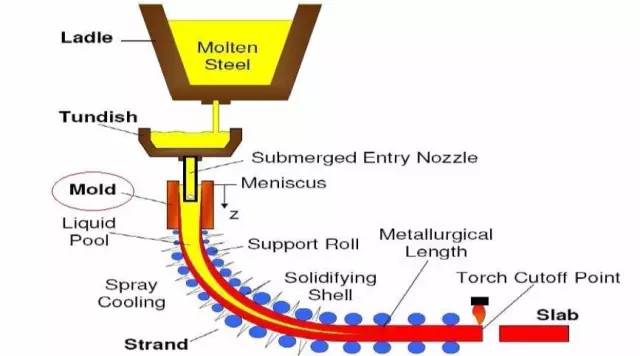

(10) Continuous casting

Continuous Casting: This is an advanced casting method. Its principle is to continuously pour molten metal into a special metal mold called a crystallizer. The solidified (crusted) castings are poured continuously to the other side of the crystallizer. it can get castings of any length or a specific length.

Process flow:

Technical characteristics:

1) Because the metal is cooled quickly, the crystallization is dense, the structure is uniform, and the mechanical properties are good;

2) Save metal and increase efficiency;

3) The process is simplified and shaping and other processes are eliminated, thereby reducing labor intensity, the required production area is also greatly reduced;

4) Continuous casting production is easy to mechanize and automate, thereby improving production efficiency.

application:

The continuous casting method can be used to cast steel, iron, copper alloys, aluminum alloys, magnesium alloys and other long castings with constant section shapes, such as ingots, slabs, bar blanks and pipes.

2. Plastic forming

Plastic forming: A process that uses the plasticity of materials to process parts with little or no cutting under the action of external forces from tools and molds. There are many types, including forging, rolling, extrusion, stamping and stamping.

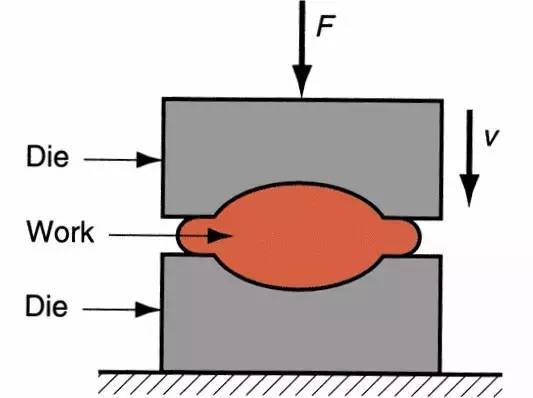

(1) Forging

Forging: This is a processing method that uses forging machines to exert pressure on metal blanks to cause plastic deformation to obtain forgings with certain mechanical properties, shapes and sizes.

According to the forming mechanism, forging can be divided into free forging, die forging, ring rolling and special forging.

Free Forging: This is generally a processing method that uses simple tools to hammer ingots or blocks of metal into the required shape and size on a forged hammer or hydraulic press.

Forging: It is formed using a die on a stamping hammer or hot stamping press.

Ring rolling: refers to the production of ring-shaped parts of different diameters by means of special equipment ring rolling machines. It is also used to produce wheel-shaped parts such as automobile hubs and train wheels.

Special forging: including forging methods such as roll forging, cross wedge rolling, radial forging and liquid pressure forging. These methods are more suitable for producing parts with certain special shapes.

Process flow: forging blank heating → forging preparation → stamping → trimming → punching → correction → intermediate inspection → heat treatment of forging → cleaning → correction → inspection.

Technical characteristics:

1) Forgings are of higher quality than castings and can withstand significant impact forces. Their plasticity, toughness and other mechanical properties are also superior to those of cast parts and even superior to those of rolled parts;

2) Save raw materials and shorten processing hours;

3) Examples of high production efficiency;

4) Free forging is suitable for single-piece and small batch production and provides greater flexibility.

application:

Herringbone rollers and gears of large steel rolling mills, rotors, wheels and retaining rings of steam turbine generators, huge cylinders and working columns of hydraulic presses, axles of locomotives, crankshafts and connecting rods of automobiles and tractors, etc. .

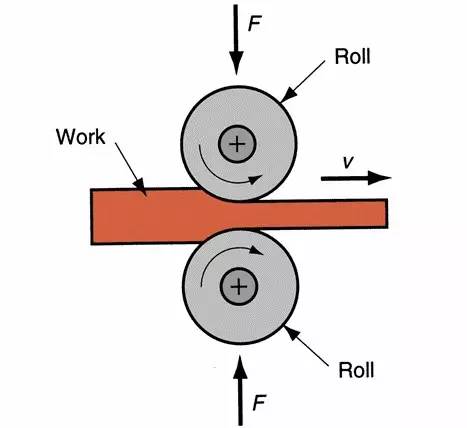

(2) Rolling

Rolling: A method of pressure processing in which the metal blank passes through the gap between a pair of rotating rollers (of different shapes) and is compressed and formed by the rollers. Rolling reduces the cross section of the material and increases the length.

Classification of rolling: According to the movement of the rolled part, it is divided into: longitudinal rolling, transverse rolling and transverse rolling.

Longitudinal rolling: It is a process in which the metal passes between two rollers rotating in opposite directions and produces plastic deformation during them.

Cross rolling: The direction of movement of the rolled part after deformation is consistent with the direction of the roller axis.

Cross rolling: the rolled part moves in a spiral, and the rolled part and the roller axis form a non-specific angle.

application:

Mainly used in profiles, plates, pipes, etc. in metallic materials, as well as in some non-metallic materials such as plastic products and glass products.

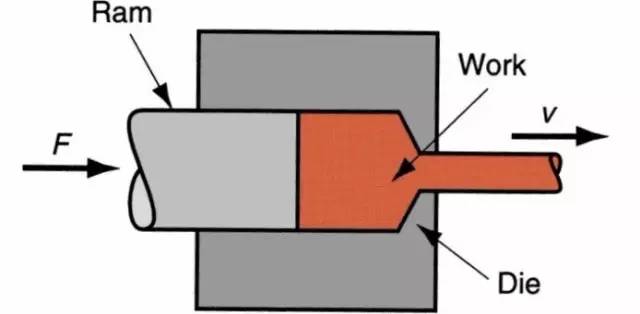

(3) Extrusion

Extrusion: under the action of unequal compressive stress in three directions, the blank is extruded from the mold hole or space to reduce the cross section and increase the length, and the processing method to become the desired product is called extrusion. This processing of the blank is called extrusion.

Process flow:

Preparation before extrusion → heating of cast rod → extrusion → drawing, twisting and straightening → sawing (to length) → sampling and inspection → manual aging → packaging and storage.

advantage:

1) Wide production range, numerous product specifications and varieties;

2) High production flexibility, suitable for small batch production;

3) The product has high dimensional accuracy and good surface quality;

4) The equipment investment is small, the factory area is small, and it is easy to realize automated production.

default:

1) Large loss of geometric waste;

2) Uneven metal flow;

3) The extrusion speed is low and the auxiliary time is long;

4) Tool loss is large and the cost is high.

Production scope: mainly used for manufacturing long rods, deep holes, thin walls and special-shaped cross-section parts.

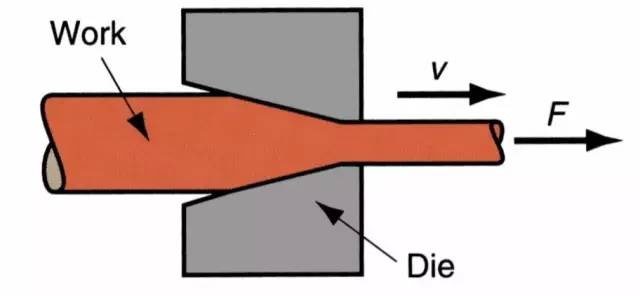

(4) Drawing

Drawing: A plastic processing method that uses external force to act on the front end of the metal to be drawn to pull the metal blank from the die hole smaller than the cross section of the blank to obtain products with shape and of corresponding size.

advantage:

1) Accurate size and smooth surface;

2) Tools and equipment are simple;

3) Continuously produce long products with small cross section at high speed.

default:

1) The amount of deformation of each pass and the total amount of deformation between two anneals are limited;

2) Length is limited.

Production scope: Drawing is the main processing method of metal pipes, bars, profiles and wires.

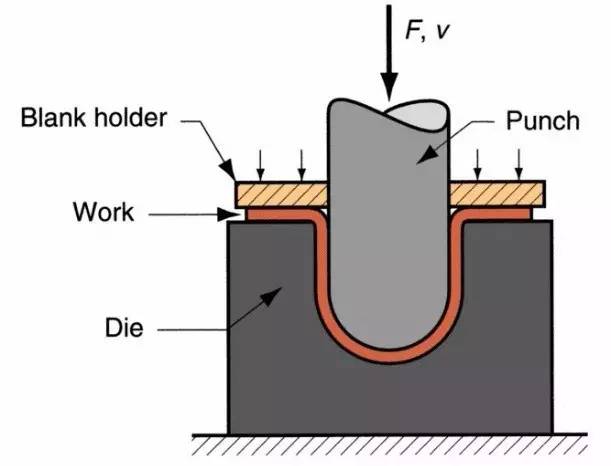

(5) Stamping

Stamping: It is a forming processing method that relies on presses and molds to apply external force to plates, strips, pipes and profiles to cause plasticity, deformation or separation, thus obtaining parts (stamping parts) of the required shape and size.

Technical characteristics:

1) Lightweight and high rigidity products can be obtained;

2) Good productivity, suitable for mass production and low cost;

3) Products of uniform quality can be obtained;

4) High material utilization, good shear and recyclability.

Scope of application:

60-70% of the world’s steel products are sheet metal, most of which is stamped to form finished products. The body, chassis, fuel tank, radiator fins of automobiles, boiler drums, container housings and silicon steel sheets of engines and electrical appliances are all stamped. There are also a large number of stamped parts in products such as instruments and meters, household appliances, bicycles, office machines and living utensils.

3. Machining

Machining: During the production process of parts, a tool is used to directly cut off the excessive thickness of the metal layer on the blank to make it conform to technical requirements such as dimensional accuracy, shape accuracy and shape accuracy. position, as well as the surface quality required by the design.

Commonly used machining methods:

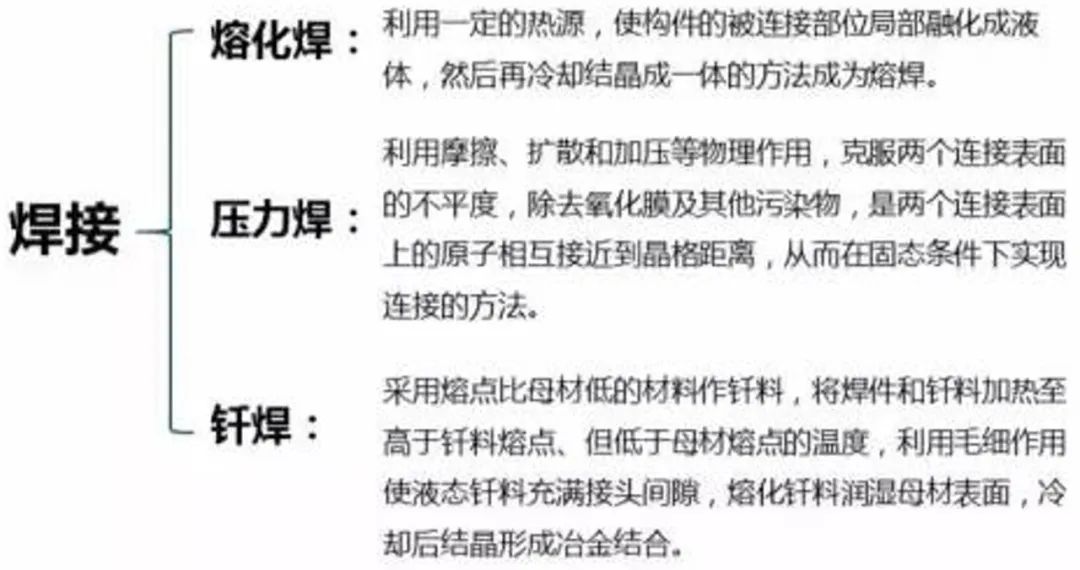

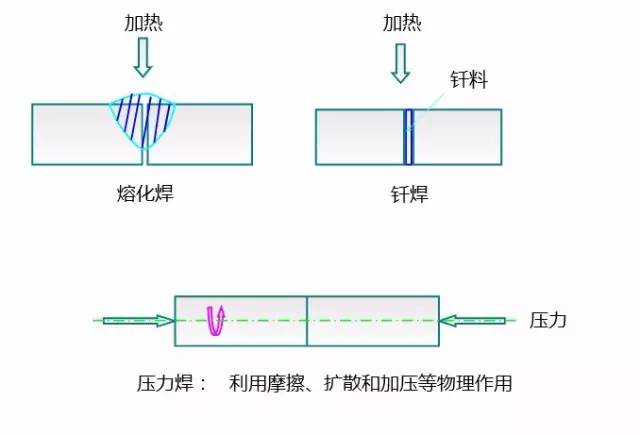

4. Welding

Welding: Also known as soldering, welding is a manufacturing process and technology that uses heat, high temperature, or high pressure to join metal or other thermoplastic materials such as plastics.

Welding classification:

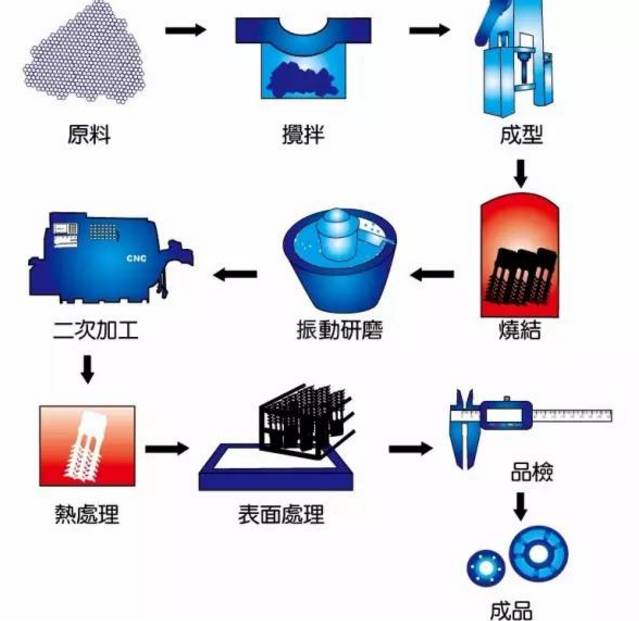

5. Powder metallurgy

Powder metallurgy: It is a processing technology that prepares metal or uses metal powder (or a mixture of metal powder and non-metallic powder) as raw material, and makes metal materials, composite materials and various types of products by shaping and sintering.

Basic process flow:

advantage:

1) Most refractory metals and their compounds, false alloys and porous materials can only be manufactured using powder metallurgy methods;

2) Save metal and reduce product costs;

3) It will not cause any pollution to the materials and it is possible to produce high purity materials;

4) Powder metallurgy can guarantee the accuracy and uniformity of material composition ratio;

5) Powder metallurgy is suitable for producing products of the same shape in large quantities and can significantly reduce production costs.

default:

1) Consider part size when there is no batch size;

2) The cost of molds is relatively higher than that of casting molds.

Production scope:

Powder metallurgy technology can directly manufacture porous, semi-dense or fully dense materials and products, such as oil-impregnated bearings, gears, cams, guide rods and cutting tools.

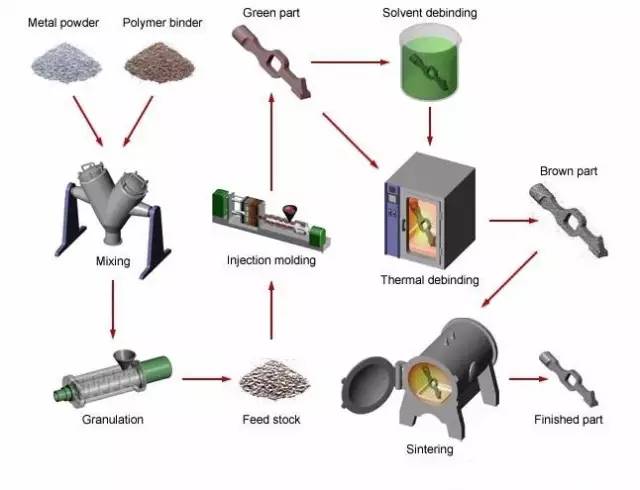

6. Metal injection molding

MIM (Metal injection Molding): is the abbreviation of metal injection molding. This is a molding process in which a plasticized mixture of metal powder and its binder is injected into the mold. This involves first mixing the selected powder with a binder, then granulating the mixture and then injection molding it into the desired shape.

MIM process flow:

The MIM process is divided into four unique processing steps (mixing, forming, degreasing and sintering) to achieve part production and determine whether surface treatment is required based on product characteristics.

Technical characteristics:

1) Unique forming parts;

2) The surface quality of parts is good, the scrap rate is low, the production efficiency is high, and it is easy to realize automation;

3) Low requirements for casting materials.

Technical core:

The binder is at the heart of MIM technology. Only by adding a certain amount of binder can the powder have improved fluidity to be suitable for injection molding and maintain the basic shape of the compact.

7. Semi-solid forming of metal

Semi-Solid Forming: Use the unique rheology and melting properties of non-dendritic semi-solid metals (semi-solid metals, called SSM) to control the quality of castings.

Semi-solid forming can be divided into flow forming and thixoforming.

(1) Rheoforming

(2) Thixoforming

Technical characteristics:

1) Reduce liquid formation defects and significantly improve quality and reliability;

2) The forming temperature is lower than the forming temperature of the full liquid, which greatly reduces the thermal impact on the mold;

3) It can produce alloys impossible to produce by conventional liquid forming methods.

application:

It has been successfully used in the manufacture of master cylinders, steering system parts, rocker arms, engine pistons, wheel hubs, transmission system parts, fuel system parts and parts air conditioning, etc. in aviation, electronics and consumer goods.

8. 3D printing

3D Printing: This is a type of rapid prototyping technology. This is a technology that uses bondable materials such as metal powder or plastic to build objects by printing layer by layer based on digital model files.

Comparison of 3D printing technologies:

Daguang focuses on providing solutions such as precision CNC machining services (3-axis, 4-axis, 5-axis machining), CNC milling, 3D printing and rapid prototyping services.